Page 5 - All Industrial Tool Supply | General Catalog

P. 5

Technical Information • DRILLS

3

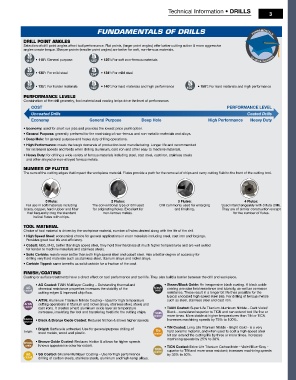

DRILL POINT ANGLES

Selection of drill point angles affect tool performance. Flat points, (larger point angles) offer better cutting action & more aggressive

angles create torque. Sharper points (smaller point angles) are better for soft, non-ferrous materials.

• 118°: General purpose • 125°: For soft non-ferrous materials

• 130°: For mild steel • 134°: For mild steel

• 135°: For harder materials • 140°: For hard materials and high performance • 150°: For hard materials and high performance

PERFORMANCE LEVELS

Combination of the drill geometry, tool material and coating helps drive the level of performance.

COST PERFORMANCE LEVEL

Uncoated Drills Coated Drills

Economy General Purpose Deep Hole High Performance Heavy Duty

• Economy: used for short run jobs and provides the lowest price point option.

• General Purpose: generally preferred for the machining of non-ferrous and non-metallic materials and alloys.

• Deep Hole: for general purpose and heavy duty drilling operations.

• High Performance: meets the tough demands of production level manufacturing. Longer life and recommended

for increased speeds and feeds when drilling aluminum, cast iron and other easy to machine materials.

• Heavy Duty: for drilling a wide variety of ferrous materials including steel, cast steel, cast iron, stainless steels

and other alloyed or non-alloyed ferrous metals.

NUMBER OF FLUTES

The sum of the cutting edges that impact the workpiece material. Flutes provide a path for the removal of chips and carry cutting fluid to the front of the cutting tool.

0 Flute: 2 Flutes: 3 Flutes: 4 Flutes:

For use in soft materials including The conventional type of drill used Drill commonly used for enlarging Used interchangeably with 3 flute drills.

brass, copper, hard rubber and fiber for originating holes. Excellent for and finishing. They are of similar construction except

that frequently clog the standard non-ferrous metals. for the number of flutes.

helical flutes with chips.

TOOL MATERIAL

Choice of tool material is driven by the workpiece material, number of holes desired along with the life of the drill.

• High Speed Steel: economical choice for general applications in most materials including steel, cast iron and forgings.

Provides good tool life and efficiency.

• Cobalt: M35, M42, better than high speed steel, they hold their hardness at much higher temperatures and are well suited

for harder to machine materials and stainless steels.

• Solid Carbide: resists wear better than both high speed steel and cobalt steel. Has a better degree of accuracy for

drilling very hard materials such as stainless steel, titanium alloys and nickel alloys.

• Carbide Tipped: same benefits as solid carbide for a fraction of the cost.

FINISH/COATING

Coating or surface treatments have a direct effect on tool performance and tool life. They also build a barrier between the drill and workpiece.

• AG Coated: TiAlN Multilayer Coating – Outstanding thermal and • Steam/Black Oxide: An inexpensive black coating. A black oxide

chemical resistance properties increases the stability of the coating provides heat resistance and lubricity, as well as corrosion

cutting edges & improved chip flow. resistance. These result in a longer bit life than possible for the

typical uncoated high speed steel bits. For drilling of ferrous metals

• AlTiN: Aluminum Titanium Nitride Coating – Ideal for high temperature such as steel, stainless steel and cast iron.

cutting operations in titanium and nickel alloys, stainless steel, steels and

cast irons. It creates a hard aluminum oxide layer as temperature • TiAIN Coated: Super Life Titanium Aluminum Nitride – Dark Violet/

increases, insulating the tool and transfering heat into the cutting chips. Black - considered superior to TiCN and can extend tool life five or

more times. More stable at higher temperatures than TiN or TiCN.

• Black & Bronze Oxide Coated: Reduces friction & allows higher speeds. Increases machining speeds by 75% to 100%.

• TiN Coated: Long Life Titanium Nitride - Bright Gold - is a very

• Bright: Surface is untreated. Use for general purpose drilling of

most metals, wood and plastic. hard ceramic material, and when used to coat a high-speed steel

bit can extend the cutting life by three or more times. Increases

machining speeds by 25% to 30%.

• Bronze Oxide Coated: Reduces friction & allows for higher speeds.

Known appearance color for cobalt. • TiCN Coated: Extra-Life Titanium Carbonitride – Violet/Blue-Gray -

superior to TiN and more wear resistant; increases machining speeds

• SG Coated: Silicone Multilayer Coating – Use for high performance by 35% to 50%.

drilling of carbon steels, stainless steels, aluminum and high-temp alloys.