Page 1812 - All Industrial Tool Supply | General Catalog

P. 1812

Technical Information Listing Acronyms & Abbreviations

1810

1810

1810

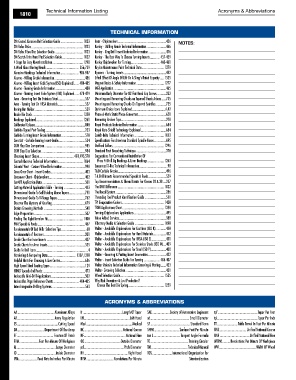

Technical informaTion

3M Coated Abrasive Belt Selection Guide ............................. 1023 Iscar - Chipbreakers ...............................................................436 Notes:

3M Roloc Disks ................................................................... 1023 Korloy - Milling Grade Technical Information ..........................466

3M Roloc Fibre Disc Selection Guide ..................................... 1023 Korloy - King Drill Insert Technical Information .......................476

3M Scotch-Brite Hand Pad Selection Guide ........................... 1032 Korloy - The Best Way To Choose Turning Inserts .............457-459

4 Steps for Easy Rivet Installation ........................................ 1298 Korloy Chipbreaker For Turning ......................................460-461

A Word About Boring Heads ........................................... 356,739 Krylon Maintenance Paint Technical Data ............................. 1379

Abrasive Markings Technical Information ........................986-987 Kyocera - Turning Inserts .......................................................452

Akuma - Milling Grade Information ........................................486 Liftall Effect Of Angle Of LIft On A Sling's Rated Capacity ..... 1535

Akuma - Milling Insert Code System (ISO) Explained .......484-485 Magnet Basics & Safety Information .................................... 1277

Akuma - Turning Grade Information .......................................480 MGT Application .....................................................................465

Akuma - Turning Insert Code System (ISO) Explained ......478-479 Minimum Body Diameter for 82 Flat Head Cap Screws ............222

Arno - Grooving Test On Stainless Steel ...................................537 Mounting and Removing Chucks on Tapered Shank Arbors ......735

Arno - Turning Test On HRSA Materials ....................................537 Mounting and Removing Chucks On Tapered Spindles ..............735

Boring Bar Holder ..................................................................529 Optimum Choice Icons Explained ...........................................4,42

Brake Die Stock .................................................................. 1310 Phase-A-Matic Static Phase Converters ....................................658

Bushings Explained ............................................................. 1261 Removing Broken Taps...........................................................278

Calibrated Calipers .................................................................840 Royal Products Technical Information ......................................684

Carbide Tipped Port Tooling ....................................................233 Royal Roto-Shield Technology Explained .................................684

Carbide Turning Insert Grade Information ...............................570 Scotch-Brite Technical Information ....................................... 1013

Ceratizit - Carbide Turning Insert Guide ...................................524 Specifications For American Standard Spindle Noses ................695

CGW Flap Disc Comparison .....................................................985 Stafford Collars ................................................................... 1296

CGW Slap Disc Selection .........................................................984 Standard Push Broaching Technique........................................370

Choosing Insert Shape ............................................. 481,495,570 Suggestions For Conventional Installation Of

Coated Abrasive Technical Information ................................. 1064 Press Fit Drill Jig Bushings & Liner Bushings ...................... 1263

Colonial West - Custom Wheel Information ..............................998 Superceed X-Roc Technical Information .....................................98

Cross Over Chart - Insert Grades .............................................403 T&O Carbide Grades ...............................................................496

Crossover Chart - Chipbreakers ...............................................402 T-A Drill Inserts Recommended Speeds & Feeds .......................559

Cut-Off Application Data ........................................................501 Tap Recommendations & Thread Limits For Classes 2B & 3B ....237

Cutting Material Application Table - Turning ............................413 The DMT Difference ............................................................ 1022

Dimensional Guide To Self Holding Morse Tapers .....................751 The Recoil System ..................................................................286

Dimensional Guide To V-Flange Tapers ....................................762 Threading Tool Product Identification Guide ............................511

Discover The Mystery of Knurling ...........................................679 TPI Evaporative Coolers ....................................................... 1420

Dorian Grooving Methods ......................................................548 TRIM Applications Chart ...................................................... 1358

Edge Preparation ...................................................................507 Turning Chipbreakers Applications ..........................................495

Finding The Right Terralux Fit .............................................. 1400 Value Added Services .............................................................388

FMA Speeds & Feeds ..............................................................467 Vibratory Media & Selection Guide ...................................... 1090

Fundamentals Of End Mills Selection Tips .................................60 Walter - Available Chipbreakers For Cast Iron (ISO K) ..............410

Fundamentals of Reamers ......................................................201 Walter - Available Chipbreakers For Hard Materials .................412

Grade Chart for Iscar Inserts ..................................................437 Walter - Available Chipbreakers For HRSA (ISO S) ...................411

Grade Charts for Arno Inserts .................................................535 Walter - Available Chipbreakers For Stainless Steels (ISO M) ....409

Guide To Drill Icons ....................................................................4 Walter - Available Chipbreakers For Steel (ISO P) ....................408

Hardening & Tempering Data ..................................... 1307,1310 Walter - Grooving & Parting Insert Geometries ........................422

Helpful Hints For Choosing A Live Center.................................686 Walter - Insert Selection Guide For Turning .....................406-407

High Speed Steel Coating Types ..............................................129 Walter Valenite Technical Information Grooving & Parting .......423

HRMD Speeds And Feeds ........................................................473 Walter- Grooving Selection .....................................................421

Indexable Mini-Drill Applications ............................................502 Wheel Selection Guide ......................................................... 1525

Indexables Page Reference Charts ..................................404-405 Why Risk Downtime & Lost Production?

Interchangeable Drilling Systems ............................................563 Choose The Best Die Spring. ............................................. 1259

acronyms & abbreviaTions

AA.............................................. Aluminum Alloys It .................................................Length Of Taper SAE ......................Society of Automotive Engineers tpf .................................................Taper Per Foot

AR.............................................. Army Regulation LH .........................................................Left Hand sd ................................................ Small Diameter tpi ..................................................Taper Per Inch

CS ...................................................Cutting Speed Med .........................................................Medical SF .................................................Standard Form TT .........................Table Travel In Feet Per Minute

DA .................................Department Of The Army NC ...............................................National Coarse SFPM ...............................Surface Feet Per Minute UNC .................................Unified National Coarse

FF ............................................. Fraction Of Finish NF ....................................................National Fine tan L .................................Tangent Angle Formula UNF .....................................Unified National Fine

FPM ........................Feet Per Minute Of Workpiece OD .............................................Outside Diameter TC ...............................................Training Circular WRPM ..........Revolutions Per Minute Of Workpiece

Id .................................................Large Diameter pd ..................................................Pitch Diameter TM .............................................Technical Manual WW ..............................................Width Of Wheel

ID ................................................Inside Diameter RH ......................................................Right Hand TOS .........................International Organization for

IPM .......................Feed Rate In Inches Per Minute RPM ..................................Revolutions Per Minute Standardization