Page 273 - All Industrial Tool Supply | General Catalog

P. 273

Spiral Pointed • TAPS

271

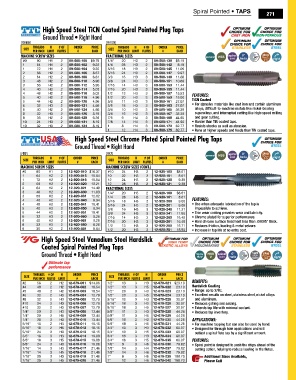

High Speed Steel TiCN Coated Spiral Pointed Plug Taps

Ground Thread • Right Hand

[F8-TiCN] [F8-TiCN]

THreadS H # Of Order PriCe THreadS H # Of Order PriCe

Size Size

Per iNCH limiT fluTeS # eaCH Per iNCH limiT fluTeS # eaCH

maCHiNe SCrew SizeS fraCTiONal SizeS

#0 80 H1 2 09-500-100 $9.79 1/4" 20 H3 2 09-500-139 $8.19

1 64 H1 2 09-500-102 9.22 1/4 28 H3 2 09-500-142 8.19

1 72 H1 2 09-500-104 9.22 5/16 18 H3 2 09-500-145 11.05

2 56 H2 2 09-500-106 8.67 5/16 24 H3 2 09-500-147 9.97

2 64 H2 2 09-500-108 6.81 3/8 16 H3 3 09-500-149 11.88

3 48 H2 2 09-500-110 5.90 3/8 24 H3 3 09-500-151 10.69

3 56 H2 2 09-500-112 5.90 7/16 14 H3 3 09-500-153 11.44

4 40 H2 2 09-500-114 5.03 7/16 20 H3 3 09-500-155 11.44

4 48 H2 2 09-500-116 5.03 1/2 13 H3 3 09-500-157 15.53 feAtures:

5 40 H2 2 09-500-118 4.96 1/2 20 H3 3 09-500-159 15.00 TiCN Coated

5 44 H2 2 09-500-120 4.96 5/8 11 H3 3 09-500-161 27.07

6 32 H3 2 09-500-121 4.66 5/8 18 H3 3 09-500-163 27.07 • For abrasive materials like cast iron and certain aluminum

6 40 H2 2 09-500-124 4.66 3/4 10 H3 3 09-500-165 35.39 alloys, difficult-to-machine metals like nickel-bearing

8 32 H3 2 09-500-126 8.19 3/4 16 H3 3 09-500-167 35.39 superalloys, and interrupted cutting like high-speed milling

8 36 H2 2 09-500-129 6.39 7/8 9 H4 3 09-500-169 44.90 and gear cutting.

10 24 H3 2 09-500-131 8.19 7/8 14 H4 3 09-500-171 44.90 • Harder than TiN coated taps.

10 32 H3 2 09-500-134 8.19 1 8 H4 3 09-500-173 62.77 • Resists shocks as well as abrasion.

1 12 H4 3 09-500-175 62.77 • Runs at higher speeds and feeds than TiN coated taps.

High Speed Steel Chrome Plated Spiral Pointed Plug Taps

Ground Thread • Right Hand

[F8CP] [F8CP]

THreadS H # Of Order PriCe THreadS H # Of Order PriCe

Size Size

Per iNCH limiT fluTeS # eaCH Per iNCH limiT fluTeS # eaCH

maCHiNe SCrew SizeS maCHiNe SCrew SizeS (CONT.)

#0 80 H1 2 12-920-010 $16.37 #10 24 H3 2 12-920-100 $8.61

1 64 H2 2 12-920-015 15.04 10 32 H3 2 12-920-101 8.61

1 72 H2 2 12-920-016 15.04 12 24 H3 2 12-920-120 9.38

2 56 H2 2 12-920-020 13.21 12 28 H3 2 12-920-121 9.38

2 64 H2 2 12-920-021 14.49 fraCTiONal SizeS

3 48 H2 2 12-920-030 11.03 1/4" 20 H3 2 12-920-160 $8.61

3 56 H2 2 12-920-031 12.02 1/4 28 H3 2 12-920-161 8.61

4 40 H2 2 12-920-040 9.34 5/16 18 H3 2 12-920-200 9.06 feAtures:

4 48 H2 2 12-920-041 10.41 5/16 24 H3 2 12-920-201 9.06 • Use when adequate lubrication of the tap is

5 40 H2 2 12-920-050 9.34 3/8 16 H3 3 12-920-240 11.31 impossible to achieve.

5 44 H2 2 12-920-051 10.41 3/8 24 H3 3 12-920-241 11.86 • Thin wear coating provides wear and lubricity.

6 32 H3 2 12-920-060 8.26 7/16 14 H3 3 12-920-260 16.48 • Chrome plated for superior performance.

6 40 H2 2 12-920-061 8.26 7/16 20 H3 3 12-920-261 16.48 • Hard chrome surface treatment less than .00005" thick.

8 32 H3 2 12-920-080 8.26 1/2 13 H3 3 12-920-280 16.71 • Reduces friction, loading & metal seizure.

8 36 H2 2 12-920-081 9.04 1/2 20 H3 3 12-920-281 18.95 • Increase in tap life at no extra cost.

High Speed Steel Vanadium Steel Hardslick

Coated Spiral Pointed Plug Taps

Ground Thread • Right Hand

Ultimate tap

performance

THreadS # Of H Order PriCe THreadS # Of H Order PriCe

Size Size

Per iNCH fluTeS limiT # eaCH Per iNCH fluTeS limiT # eaCH

#2 56 2 H2 12-679-001 $14.06 1/2" 13 3 H3 12-679-021 $23.10 Benefits:

#4 40 2 H2 12-679-002 10.54 1/2" 13 3 H5 12-679-022 23.10 Hardslick Coating

#5 40 2 H2 12-679-003 10.54 1/2" 20 3 H3 12-679-023 23.10 • Range: up to 37Rc.

#6 32 2 H3 12-679-004 12.79 1/2" 20 3 H5 12-679-024 23.10 • Excellent results on steel, stainless steel, nickel alloys

#8 32 2 H3 12-679-005 12.79 9/16" 12 3 H3 12-679-025 30.97 and aluminum.

#10 24 2 H3 12-679-006 12.79 9/16" 18 3 H3 12-679-026 30.97 • Reduces galling and seizing.

#10 32 2 H3 12-679-007 12.79 9/16" 18 3 H5 12-679-027 30.97 • Extends tap life with minimal coolant.

1/4" 20 2 H3 12-679-008 13.44 5/8" 11 3 H3 12-679-028 44.26 • Reduces tap inventory.

1/4" 20 2 H5 12-679-009 13.44 5/8" 11 3 H5 12-679-029 44.26

1/4" 28 3 H3 12-679-010 13.44 5/8" 18 3 H3 12-679-030 44.26 APPLiCAtiOns:

5/16" 18 2 H3 12-679-011 18.15 5/8" 18 3 H5 12-679-031 44.26 • For machine tapping but can also be used by hand.

5/16" 18 2 H5 12-679-012 18.15 3/4" 10 3 H3 12-679-032 60.07 • Designed for through hole applications and will

5/16" 24 3 H3 12-679-013 18.15 3/4" 10 3 H5 12-679-033 60.07 outlast a spiral flute tap by a significant amount.

3/8" 16 3 H3 12-679-014 19.08 3/4" 16 3 H3 12-679-034 60.07

3/8" 16 3 H5 12-679-015 19.08 3/4" 16 3 H5 12-679-035 60.07 feAtures:

3/8" 24 3 H3 12-679-016 19.08 7/8" 9 3 H6 12-679-036 79.82 • Spiral point is designed to push the chips ahead of the

7/16" 14 3 H3 12-679-017 21.46 7/8" 14 3 H4 12-679-037 79.82 cutting action, helping to reduce loading in the flutes.

7/16" 14 3 H5 12-679-018 21.46 7/8" 14 3 H6 12-679-038 79.82

7/16" 20 3 H3 12-679-019 21.46 1" 8 3 H6 12-679-039 108.73 Additional Sizes Available,

7/16" 20 3 H5 12-679-020 21.46 1" 12 3 H6 12-679-040 108.73 Please Call