Page 279 - All Industrial Tool Supply | General Catalog

P. 279

High Performance Thread Forming • TAPS

277

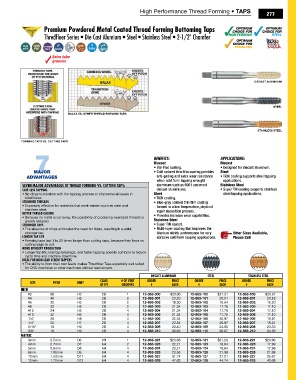

Premium Powdered Metal Coated Thread Forming Bottoming Taps

Thredfloer Series • Die Cast Alumium • Steel • Stainless Steel • 2-1/2" Chamfer

Extra lube

grooves

diecAST Aluminum

STeel

BAlAx vS. OTher ThreAd FOrming TAPS

STAinleSS STeel

FOrming TAPS vS. cuTTing TAPS

7 Benefits: APPLiCAtiOns:

Diecast

Diecast

major • Bal-Plus coating. • Designed for diecast aluminum.

• Gold colored thin-film coating provides

Steel

advantages anti-galling and extra wear resistance • TiCN coating supports steel tapping

when cold form tapping wrought applications.

Seven Major advanTageS oF Thread ForMing vS. CuTTing TaPS: aluminum such as 6061 and most Stainless Steel

ChiP-LeSS TaPPing diecast aluminiums. • Super TiN coating supports stainless

• No chips to interfere with the tapping process or chip removal issues in Steel steel tapping applications.

blind holes. • TiCN coating.

STronger ThreadS • Blue-gray colored thin film coating

• Especially effective for materials that work-harden such as steel and formed in a low temperature, physical

stainless steel. vapor deposition process.

BeTTer Thread gaging • Provides increase wear capabilities.

• Because no metal is cut away, the possibility of producing oversized threads is

greatly reduced. Stainless Steel

STronger TaPS • Super TiN coated.

• The absence of chips eliminates the need for flutes, resulting in a solid, • Multi-layer coating that improves the

stronger tap. titanium nitride performance for very Other Sizes Available,

Longer TaP LiFe abrasive cold form tapping applications. Please Call

• Forming taps last 3 to 20 times longer than cutting taps, because they have no

cutting edge to dull.

More eFFiCienT ProduCTion

• Longer tap life, less tap breakage, and faster tapping speeds combine to reduce

cycle time and machine downtime.

ideaL For non-Lead SCrew TaPPerS

• The ability to form their own leads makes Thredfloer Taps especially well suited

for CNC machines or other machines without lead screws.

dieCaST aLuMinuM STeeL STainLeSS STeeL

CLaSS # oF venT order PriCe order PriCe order PriCe

Size PiTCh LiMiT

oF FiT grooveS # eaCh # eaCh # eaCh

inCh

#2 56 H3 2B 1 12-863-000 $23.00 12-863-100 $21.21 12-863-200 $20.87

#4 40 H5 2B 2 12-863-001 22.29 12-863-101 20.51 12-863-201 20.18

#6 32 H5 2B 2 12-863-002 18.30 12-863-102 16.54 12-863-202 16.20

#8 32 H5 2B 2 12-863-003 21.34 12-863-103 17.76 12-863-203 17.10

#10 24 H5 2B 4 12-863-004 21.34 12-863-104 17.76 12-863-204 17.10

#10 32 H5 2B 4 12-863-005 21.34 12-863-105 17.76 12-863-205 17.10

1/4" 20 H8 2B 4 12-863-006 22.54 12-863-106 20.97 12-863-206 19.81

1/4" 28 H7 2B 4 12-863-007 22.54 12-863-107 20.97 12-863-207 19.81

5/16" 18 H9 2B 4 12-863-008 29.40 12-863-108 24.85 12-863-208 23.33

3/8" 16 H9 2B 4 12-863-010 30.62 12-863-110 26.07 12-863-210 24.55

MeTriC

3mm 0.5mm D6 6H 1 12-863-021 $23.08 12-863-121 $21.29 12-863-221 $20.96

4mm 0.7mm D7 6H 2 12-863-023 22.21 12-863-123 18.64 12-863-223 17.99

5mm 0.8mm D8 6H 4 12-863-024 22.21 12-863-124 18.64 12-863-224 17.99

6mm 1.00mm D9 6H 4 12-863-025 23.55 12-863-125 21.98 12-863-225 21.98

10mm 1.50mm D11 6H 4 12-863-027 31.74 12-863-127 27.21 12-863-227 25.67

12mm 1.75mm D12 6H 4 12-863-028 47.02 12-863-128 44.74 12-863-228 43.08