Page 583 - All Industrial Tool Supply | General Catalog

P. 583

Technical Turning • ARNO WERKZEUGE

581

ChipbREAKER & GRAdE iNfORmAtiON

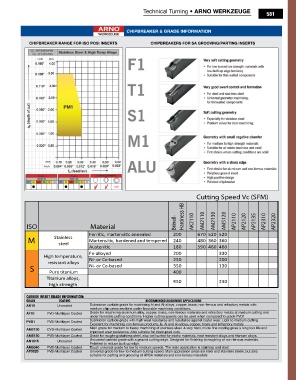

ChipbREAKER RANGE fOR iSO pOSi iNSERtS ChipbREAKERS fOR SA GROOViNG/pARtiNG iNSERtS

Cutting Speed Vc (SFM)

Brinell- Hardness HB AK2110 AM2110 AM2130 AM5120 AP2110 AP2120 AP2135 AP2310 AP2320

ISO Material

Ferric, martensic annealed 200 670 520 520

M Stainless Martensic, hardened and tempered 240 480 360 360

steel

Austenic 180 590 460 460

Fe-alloyed 200 330

High temperature,

resistant alloys Ni- or Co-based 250 200

S Pure tanium Ni- or Co-based 350 130

400

Titanium alloys, 950 230

high strength

carbide insert grade information:

grade coating recommended macHining aPPLications

AK10 Uncoated Submicron carbide grade for machining Al and Al-alloys, copper, brass, non-ferrous and refractory metals with

medium chip cross sections under favorable machining conditions.

At10 PVD-Multilayer Coated Grade for machining aluminum alloy, copper, brass, non-ferrous materials and refractory metals at medium cutting and

under favorable cutting conditions. Higher cutting speeds can be used when compared to grade PVD1

pVd1 PVD-Multilayer Coated Submicron carbide grade with high wear resistance and resistance against crater wear. Light to medium cutting.

Excellent for machining non-ferrous products, ie. Al and Al-alloys, copper, brass and refractory metals.

Am2130 CVD-Multilayer Coated Main grade for medium to heavy machining of stainless steel. A very hard, micro fine coating gives a long tool life and

improved wear resistance. Also suitable for interrupted cuts.

Am5120 PVD-Multilayer Coated Grade for roughing stainless steel, also well suited for exotic materials, heat resistant alloys and titanium alloys.

AN1015 Uncoated Uncoated carbide grade with a ground cutting edge. Designed for finishing to roughing of non-ferrous materials.

Polished to reduce built up edge.

Am5040 PVD-Multilayer Coated Tough universal grade for low to medium speeds. The main application is stainless and steel.

Ap5020 PVD-Multilayer Coated Universal grade for low to medium cutting speed. Main application areas are steel and stainless steels, but also

suitable for parting and grooving of HRSA materials and non-ferrous materials.