Page 1464 - Ceratizit Catalog

P. 1464

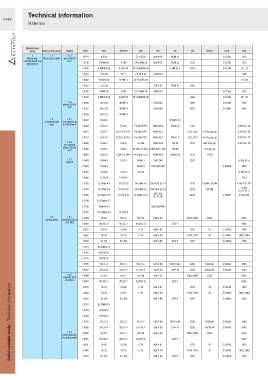

Technical information

F467

Materials

Material main

group Material sub-group Quality StNr DIN AFNOR UNI BS JIS SS GOST UNS USA

1 1.1 1.1.1 1.0711 9 S 20 CF 9 S 22 220 M 07 SUM 21 G 12120 1212

Machining, Machining steels up to 500 N/

constructional and mm 2 1.0715 9 SMn 28 S 250 CF 9 SMn 28 230 M 07 SUM 22 1912 G 12130 1213

spring steel

1.0718 9 SMnPb 28 S 250 Pb CF 9 SMnPb 28 SUM 22 L 1914 G 12134 12 L 13

1.0721 10 S 20 10 F 1 CF 10 S 20 210 M 15 1108

1.0722 10 SPb 20 10 PbF 2 CF 10 SPb 20 11 L 08

1.0723 15 S 20 210 A 15 SUM 32 1922

1.0736 9 SMn 36 S 300 CF 9 SMn 36 240 M 07 G 12150 1215

1.0737 9 SMnPb 36 S 300 Pb CF 9 SMnPb 36 1926 G 12144 12 L 14

1.1.2 1.0726 35 S 20 35 MF 4 212 M 36 1957 G 11400 1140

above 500 N/

mm 2

1.0727 45 S 20 45 MF 4 212 M 44 1973 G 11460 1146

1.0728 60 S 20 60 MF 4

1.2 1.2.1 1.0037 St 37-2 STKM 12 C

Constructional non alloyed up

steel to 500 N/mm 2

1.0044 St 44-2 E 28-2 Fe 430 B FN 4360-43 B SM 41 B 1412 A 570 Gr. 40

1.0116 St 37-3 E 24-3; E 24-4 Fe 360 D FF 4360-40 C 1312; 1313 St 3 kp; ps; sp A 573 Gr. 58

1.0144 St 44-3 E 28-3; E 28-4 Fe 430 D FF 4360-43 C SM 41 C 1412; 1414 St 4 kp; ps; sp A 573 Gr. 70

1.2.2 1.0050 St 50-2 A 50-2 Fe 490 4360-50 B SS 50 2172 BSt 5 ps; sp A 570 Gr. 50

non alloyed

above 500 N/ 1.0060 St 60-2 A 60-2 Fe 590; Fe 60-2 4360-SSE; SSC SM 58 St 6 ps; sp

mm 2

1.0570 St 52-3 E 36-3; E 36-4 Fe 510 B; C; D 4360-50 B SM 50 YA 2132 17 GS

1.2.3 1.5415 15 Mo 3 15 D 3 16 Mo 3 1501-240 2912 A 204 Gr. A

alloyed

1.5423 16 Mo 5 16 Mo 5 1503-245-420 G 45200 4520

1.5622 14 Ni 6 16 N 6 14 Ni 6 A 350-LF 5

1.5680 12 Ni 19 Z 18 N 5 2515

1.7335 13 CrMo 4 4 15 CD 3.5 14 CrMo 4 5 1501-620 Gr. 27 2216 12ChM; 15ChM A 182-F11; F12

A 387

1.7337 16 CrMo 4 4 15 CD 4.5 14 CrMo 4 5 1501-620 Gr. 27 2216 15ChM

Gr. 12 Cl. 2

1501-622

1.7380 10 CrMo 9 10 10 CD 9.10 12 CrMo 9 10 2218 J 21890 A 182-F22

Gr. 31; 45

1.7709 21 CrMoV 5 7

1.7715 14 MoV 6 3 1503-660-440

1.7735 14 CrMoV 6 9 15 CDV 6

1.3 1.3.1 1.0904 55 Si 7 55 S 7 55 Si 8 250 A 53 2085; 2090 55S2 9255

Spring steel annealed (up to

250 HB)

1.0961 60 SiCr 7 60 SC 7 60 SiCr 8 SUP 7 9262

1.1231 Ck 67 XC 68 C 70 060 A 67 1770 70 G 10700 1070

1.1248 Ck 75 XC 75 C 75 060 A 78 1774; 1778 75 G 10780 1078; 1080

1.1274 Ck 101 XC 100 060 A 96 SUP 4 1870 G 10950 1095

1.2101 62 SiMnCr 4

1.2103 58 SiCr 8

1.7103 67 SiCr 5

1.7176 55 Cr 3 55 C 3 55 Cr 3 527 A 60 SUP 9 (A) 2253 50ChGA G 51550 5155

1.8159 50 CrV 4 50 CV 4 51 CrV 4 735 A 50 SUP 10 2230 50ChGFA G 61500 6150

1.3.2 1.0904 55 Si 7 55 S 7 55 Si 8 250 A 53 2085; 2090 55S2 9255

naturally hard

materials

1.0961 60 SiCr 7 60 SC 7 60 SiCr 8 060 A 67 SUP 7 1774; 1778 70 G 10700 1078; 1080

9262

Solid carbide tools / Technical information for spring steel 1.2101 62 SiMnCr 4 50 CV 4 60 SiCr 8 527 A 60 SUP 9 (A) 2085; 2090 50ChGFA G 51550 1078; 1080

1070

C 70

1.1231

XC 68

1770

Ck 67

C 75

Ck 75

XC 75

G 10780

75

1.1248

060 A 78

1870

XC 100

G 10950

060 A 96

SUP 4

1095

1.1274

Ck 101

1.2103

58 SiCr 8

67 SiCr 5

1.7103

55 Cr 3

1.7176

55 Cr 3

5155

50ChGA

2253

55 C 3

735 A 50

G 61500

2230

1.8159

SUP 10

50 CrV 4

51 CrV 4

6150

1.3.3

55 S 7

1.0904

55 Si 7

55 Si 8

250 A 53

55S2

9255

hard materials

60 SC 7

60 SiCr 7

1.0961

SUP 7

9262

Ck 67

70

C 70

060 A 67

1070

1.1231

G 10700

1770

XC 68

G 10780

C 75

060 A 78

XC 75

1.1248

Ck 75

1774; 1778

75

Ck 101

1095

1.1274

1870

SUP 4

060 A 96

XC 100

G 10950