Page 15 - Superior Abrasives sold by All Industrial Tool Supply

P. 15

Nonwoven Abrasives 13

Nonwoven Characteristics

All SHUR-BRITE® Nonwoven Abrasives consistently feature three components

- nylon fibers, abrasive grains and resin . Each component is equally important

and cannot perform a proper task without the others . The key to SHUR-BRITE®

Nonwoven Abrasives are the nylon fibers, which give products their dimensional,

open structure, and control the conformability .

The synthetic fiber structure, or fleece, is impregnated with abrasive grains and

resins . The grains attach to the fiber, and the resin bonds these components to-

gether, leaving open areas throughout the nonwoven structure . Synthetic nylon

fibers are the cushioning foundation which carry the grain media providing the

cutting action .

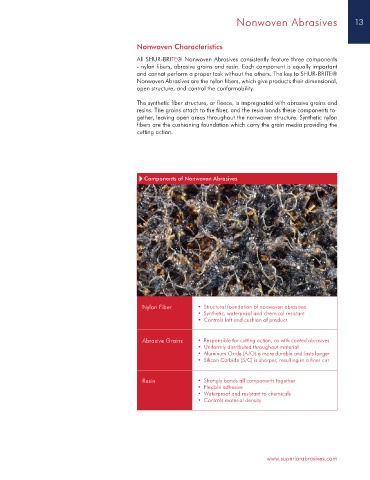

Components of Nonwoven Abrasives

Nylon Fiber • Structural foundation of nonwoven abrasives

• Synthetic, waterproof and chemical resistant

• Controls loft and cushion of product

Abrasive Grains • Responsible for cutting action, as with coated abrasives

• Uniformly distributed throughout material

• Aluminum Oxide (A/O) is more durable and lasts longer

• Silicon Carbide (S/C) is sharper, resulting in a finer cut

Resin • Strongly bonds all components together

• Flexible adhesive

• Waterproof and resistant to chemicals

• Controls material density

www .superiorabrasives .com