Page 350 - Tungaloy Catalog

P. 350

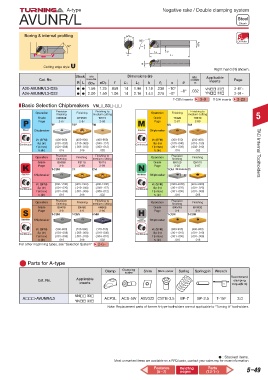

A-type Negative rake / Double clamping system

AVUNR/L Steel

Shank

Boring & internal profiling øDm

93° Oil Hole

øDs

50° f

L2 f2

α L1

U θ

Cutting edge style

Right hand (R) shown.

Stock Min Dimensions (in) Std. Applicable

Cat. No. bore.dia. corner inserts Page

R L ØDm øDs f L1 L2 h f2 α θ rε

A20-AVUNR/L3-D25 d d 1.56 1.25 .859 14 1.96 1.18 .236 −10° −6° .032 VNoo 33o 2-87~

A24-AVUNR/L3-D32 d d 2.00 1.50 1.06 14 2.16 1.44 .275 −8° YNoo 33o 2-91~

T-CBN inserts 3-9 T-DIA inserts 3-23

Basic Selection Chipbreakers VNuu33u-uu

Finishing to

Finishing to

Operation Precision Finishing medium cutting Operation Finishing medium cutting

finishing

Grade NS9530 GT9530 T9115 Grade T6120 T6130 5

Page 2-87 2-87 2-89 Page 2-87 2-89

TF TSF TM SS SM

Steel Chipbreaker Stainless Chipbreaker

Vc (SFM) (400-800) (400-900) (400-900) Vc (SFM) (300-550) (250-400)

ap (in) (.001-.020) (.010-.060) (.040-.157) ap (in) (.010-.040) (.010-.150)

Continuous Continuous

f (in/rev) (.001-.008) (.003-.010) (.003-.012) f (in/rev) (.001-.008) (.003-.012)

rε (in) .016 .016 .032 rε (in) .016 .032

Precision Finishing to Precision TAC Internal Toolholders

Operation Finishing Operation Finishing

finishing medium cutting finishing

Grade BX930 T5115 T5115 Grade DX120 GH110

Page 3-9 2-88 2-89 Page 3-23 2-87

T-CBN CF CM T-DIA With chipbreaker 01

Cast lron Chipbreaker Non-ferrous Chipbreaker

Vc (SFM) (300-1200) (450-1300) (400-1300) Vc (SFM) (1500-4000) (400-3000)

ap (in) (.001-.020) (.010-.040) (.040-.157) ap (in) (.001-.025) (.001-.025)

Continuous Continuous

f (in/rev) (.001-.006) (.001-.006) (.006-.012) f (in/rev) (.001-.006) (.001-.008)

rε (in) .016 .016 .032 rε (in) .016 .008

Operation Precision Finishing Finishing to Operation Precision Finishing

finishing medium cutting finishing

Grade BX470 BX480 AH905 Grade BXM10 BXM20

Page 3-9 3-9 2-90 Page 3-9 3-9

T-CBN T-CBN HMM T-CBN T-CBN

Hard

Superalloys Chipbreaker Materials Chipbreaker

Vc (SFM) (300-800) (230-900) (120-350) Vc (SFM) (800-900) (400-800)

ap (in) (.003-.008) (.003-.008) (.010-.040) ap (in) (.001-.010) (.001-.010)

Continuous Continuous

f (in/rev) (.001-.006) (.001-.010) (.004-.010) f (in/rev) (.001-.006) (.001-.006)

rε (in) .016 .016 .032 rε (in) .016 .016

For other machining types, see “Selection System” 2-6~

Parts for A-type

Clamp Clamping Shim Shim screw Spring Springpin Wrench

screw

Recommend

Cat. No. Applicable clamping

inserts torque(N·m)

VNoo 33o

Ahhh-AVUNR/L3 ACP3L ACS-5W ASV322 CSTB-3.5 BP-7 SP-2.5 T-15F 3.0

YNoo 33o

Note: Replacement parts of former A-type toolholders are not applicable to “Turning A” toolholders.

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Features Relating Parts 5–49

(5-7) pages (13-1~)