Page 357 - Tungaloy Catalog

P. 357

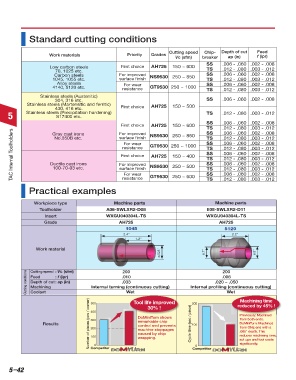

Standard cutting conditions

Cutting speed Chip- Depth of cut Feed

Work materials Priority Grades

Vc (sfm) breaker ap (in) f (ipr)

SS .006 - .060 .002 - .008

Low carbon steels First choice AH725 150 ~ 600 TS .012 - .080 .003 - .012

70, 1025 etc.

Carbon steels For improved NS9530 250 ~ 850 SS .006 - .060 .002 - .008

1045, 1055 etc. surface finish TS .012 - .080 .003 - .012

Alloy steels For wear SS .006 - .060 .002 - .008

4140, 5120 etc. resistance GT9530 250 ~ 1000 TS .012 - .080 .003 - .012

Stainless steels (Austenitic)

304, 316 etc. SS .006 - .060 .002 - .008

Stainless steels (Martensitic and ferritic) AH725 150 ~ 500

430, 416 etc. First choice

5 Stainless steels (Precipitation hardening) TS .012 - .080 .003 - .012

S17400 etc.

SS .006 - .060 .002 - .008

AH725

First choice NS9530 150 ~ 600 TS .012 - .080 .003 - .012

TAC Internal Toolholders Ductile cast irons For improved GT9530 250 ~ 1000 SS .006 - .060 .002 - .008

.006 - .060 .002 - .008

SS

For improved

Gray cast irons

250 ~ 850

surface finish

.012 - .080 .003 - .012

No.350B etc.

TS

For wear

resistance

TS

.012 - .080 .003 - .012

SS

.006 - .060 .002 - .008

AH725

First choice

150 ~ 400

.012 - .080 .003 - .012

TS

SS

.006 - .060 .002 - .008

NS9530

250 ~ 500

100-70-03 etc.

.012 - .080 .003 - .012

TS

surface finish

For wear

TS

.012 - .080 .003 - .012

Practical examples resistance GT9530 250 ~ 600 SS .006 - .060 .002 - .008

Workpiece type Machine parts Machine parts

Toolholder A06-SWLXR2-D08 E08-SWLXR2-D11

Insert WXGU040304L-TS WXGU040304L-TS

Grade AH725 AH725 Relating

1045 5120 pages

2.4" 2.2"

1.2"

Work material

ø.525" ø.7" ø.8"

Cutting speed : Vc (sfm) 200 200

Feed : f (ipr) .010 .006

Cutting conditions Depth of cut : ap (in) .033 .020 ~ .050

Machining Internal turning (continuous cutting) Internal profiling (continuous cutting)

Coolant 500 Wet Tool life improved 200 Wet reduced by 45% !

Machining time

30% !

from both ends.

300

remarkable chip

DoMiniTurn: Machined

Results Number of pieces (pcs / corner) 400 DoMiniTurn shows Cycle time (sec / piece) 100 Previously: Machined

control and prevents

from ONE end with a

200

machine stoppages

.085" depth. This

caused by chip

reduces machining time,

100

wrapping.

set ups and tool costs

significantly.

0

0

Competitor

Competitor

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

5–42