Page 13 - All Industrial Tool Supply | General Catalog

P. 13

Jobbers • DRILLS

11

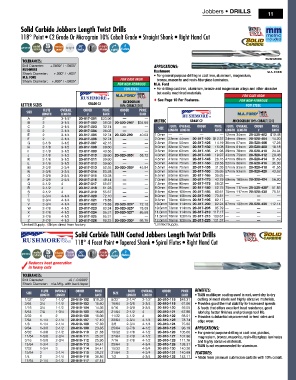

Solid Carbide Jobbers Length Twist Drills

118° Point • C2 Grade Or Micrograin 10% Cobalt Grade • Straight Shank • Right Hand Cut

RuShmoRe

ToLeranCeS:

Drill Diameter: +.0000" / -.0005" APPLICATIONS:

ruShmore

Shank Diameter: +.000" / -.001"

Rushmore m.A. FoRD

m.a. ForD • For general purpose drilling in cast iron, aluminum, magnesium,

For Cast Iron bronze, masonite and resin-fiberglass laminates.

Shank Diameter: +.000" / -.0005"

For non-Ferrous M.A. Ford

For steel • For drilling cast iron, aluminum, bronze and magnesium alloys and other abrasive

but easily machined materials.

For Cast Iron

miCrograin ♦ See Page 10 For Features. For non-Ferrous

LeTTer SizeS graDe C2 10% CobaLT [204] For steel

FLuTe

Size LengTh overaLL orDer PriCe orDer PriCe

eaCh

eaCh

#

LengTh

#

A 2" 3-1/4" 20-817-001 $33.96 — — meTriC graDe C2

B 2 3-1/4 20-817-002 36.02 20-520-296* $34.86 miCrograin 10% CobaLT [224]

C 2 3-1/4 20-817-003 32.74 — — Size FLuTe overaLL orDer PriCe FLuTe overaLL orDer PriCe

D 2 3-1/4 20-817-004 36.02 — — LengTh LengTh # eaCh LengTh LengTh # eaCh

E 2 3-1/4 20-817-005 32.74 20-520-299 40.03 1.0mm — — — — 12mm 34mm 20-520-402 $10.48

F 2 3-1/4 20-817-006 32.74 — — 2.0mm 22mm 44mm 20-817-120 $12.37 24mm 49mm 20-520-404 14.20

G 2-1/8 3-1/2 20-817-007 42.18 — — 2.5mm 25mm 50mm 20-817-125 14.19 30mm 57mm 20-520-406 17.25

H 2-1/8 3-1/2 20-817-008 39.60 — — 3.0mm 32mm 57mm 20-817-130 15.08 33mm 61mm 20-520-408 18.18

I 2-1/8 3-1/2 20-817-009 43.56 — — 3.5mm 35mm 63mm 20-817-135 21.98 39mm 70mm 20-520-410 24.04

J 2-1/8 3-1/2 20-817-010 39.60 20-520-305† 58.72 4.0mm 35mm 63mm 20-817-140 19.97 43mm 75mm 20-520-412 29.46

K 2-1/8 3-1/2 20-817-011 39.60 — — 4.5mm 41mm 70mm 20-817-145 26.15 47mm 80mm 20-520-414 31.59

L 2-1/8 3-1/2 20-817-012 39.60 — — 5.0mm 44mm 75mm 20-817-150 28.53 52mm 86mm 20-520-416 35.03

M 2-3/8 3-3/4 20-817-013 52.58 20-520-309* 45.94 5.5mm 44mm 75mm 20-817-155 31.38 57mm 93mm 20-520-418 41.55

N 2-3/8 3-3/4 20-817-014 53.28 — — 6.0mm 50mm 82mm 20-817-160 35.65 57mm 93mm 20-520-420 43.52

O 2-3/8 3-3/4 20-817-015 53.28 — — 6.5mm 50mm 82mm 20-817-165 35.65 — — — —

P 2-3/8 3-3/4 20-817-016 48.44 — — 7.0mm 54mm 89mm 20-817-170 43.79 69mm 109mm 20-520-424 56.80

Q 2-1/2 4 20-817-017 55.67 — — 7.5mm 60mm 95mm 20-817-175 58.02 — — — —

R 2-1/2 4 20-817-018 61.23 — — 8.0mm 60mm 95mm 20-817-180 52.75 75mm 117mm 20-520-428* 51.83

S 2-1/2 4 20-817-019 55.67 — — 8.5mm 63mm 100mm 20-817-185 60.61 75mm 117mm 20-520-430 75.51

T 2-3/4 4-1/4 20-817-020 72.10 — — 9.0mm 70mm 100mm 20-817-190 73.51 — — — —

U 2-3/4 4-1/4 20-817-021 76.88 — — 9.5mm 70mm 108mm 20-817-195 82.17 — — — —

V 2-3/4 4-1/4 20-817-022 76.88 20-520-324* 72.10 10.0mm 73mm 114mm 20-817-200 92.24 87mm 133mm 20-520-436 112.14

W 2-7/8 4-1/2 20-817-023 93.34 20-520-325* 78.09 10.5mm 73mm 114mm 20-817-205 95.79 — — — —

X 2-7/8 4-1/2 20-817-024 95.31 20-520-327* 85.58 11.0mm 73mm 114mm 20-817-210 117.17 — — — —

Y 2-7/8 4-1/2 20-817-025 95.31 — — 11.5mm 76mm 120mm 20-817-215 133.67 — — — —

Z 2-7/8 4-1/2 20-817-026 99.23 20-520-330* 96.76 12.0mm 76mm 120mm 20-817-220 131.37 — — — —

*Limited Supply. †Ships direct from factory. *Limited Supply.

Solid Carbide Tialn Coated Jobbers Length Twist Drills

118° 4 Facet Point • Tapered Shank • Spiral Flutes • Right Hand Cut

Reduces heat generation

in heavy cuts

ToLeranCeS:

Drill Diameter: +0 / -0.0005"

Shank Diameter: n/a-Mfg. with back taper

FLuTe overaLL orDer PriCe FLuTe overaLL orDer PriCe BeNefITS:

Size Size

LengTh LengTh # eaCh LengTh LengTh # eaCh • TiAlN multilayer coating used in wet, semi-dry to dry

1/32" 1/2" 1-1/2" 20-810-102 $19.39 9/32" 2-1/4" 3-1/2" 20-810-118 $48.31 cutting of most steels and highly abrasive materials.

3/64 3/4 1-1/2 20-810-103 15.60 19/64 2-3/8 3-3/4 20-810-119 61.66 • Provides good thermal stability for increased speeds

1/16 3/4 1-1/2 20-810-104 14.36 5/16 2-3/8 3-3/4 20-810-120 56.05 & feeds that offers excellent heat resistance, good

5/64 7/8 1-3/4 20-810-105 16.05 21/64 2-1/2 4 20-810-121 67.86 lubricity, better finishes and prolongs tool life.

3/32 1 2 20-810-106 15.06 11/32 2-1/2 4 20-810-122 68.51 • Provides substantial improvement in feed rates and

7/64 1-1/4 2-1/4 20-810-107 17.10 23/64 2-3/4 4-1/4 20-810-123 78.74 edge wear.

1/8 1-1/4 2-1/4 20-810-108 17.89 3/8 2-3/4 4-1/4 20-810-124 75.68

9/64 1-3/8 2-1/2 20-810-109 23.85 25/64 2-7/8 4-1/2 20-810-125 96.19 APPLICATIONS:

5/32 1-3/8 2-1/2 20-810-110 21.68 13/32 2-7/8 4-1/2 20-810-126 105.60 • For general purpose drilling in cast iron, plastics,

11/64 1-5/8 2-3/4 20-810-111 25.37 27/64 2-7/8 4-1/2 20-810-127 107.96 magnesium, bronze, masonite, resin-fiberglass laminates

3/16 1-5/8 2-3/4 20-810-112 25.95 7/16 2-7/8 4-1/2 20-810-128 111.76 and highly abrasive materials.

13/64 1-3/4 3 20-810-113 34.41 29/64 3 4-3/4 20-810-129 138.31 • TiAlN is not recommended for aluminum.

7/32 1-3/4 3 20-810-114 34.41 15/32 3 4-3/4 20-810-130 140.20

15/64 2 3-1/4 20-810-115 39.27 31/64 3 4-3/4 20-810-131 140.69 feATureS:

1/4 2 3-1/4 20-810-116 36.86 1/2 3 4-3/4 20-810-132 142.11 • Made from premium submicron carbide with 10% cobalt.

17/64 2-1/4 3-1/2 20-810-117 47.14