Page 1103 - All Industrial Tool Supply | General Catalog

P. 1103

Technical Information • DIAMOND TOOLING

1101

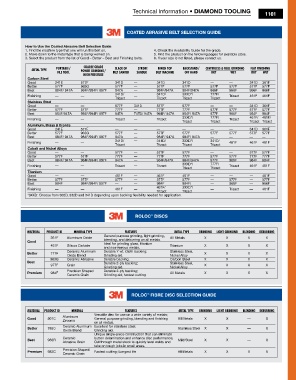

COATeD AbrAsIve beLT seLeCTION GuIDe

How to use the Coated Abrasive belt selection Guide

1. Find the machine type that you will run this belt on. 4. Check the Availability Guide for the grade.

2. Move down to the metal type that is being worked on. 5. Find the product on the following pages for available sizes.

3. Select the product from the list of Good – Better – Best and Finishing belts. 6. If your size is not listed, please contact us.

Coarse Grade

slaCk of

stroke

benCh top

Metal type portable/ power GrindinG/ belt sander sander belt MaChine baCkstand/ Centerless & roll GrindinG flat finishinG

wet

file tool

wet

dry

off hand

dry

hiGh pressure

Carbon steel

Good 241E 577F 341D — 341D 341D — — 341D 361F

Better 577F 963G 577F — 577F 577F 577F 577F 577F 577F

Best 984F/ 947A 984F/994F/ 997F 947A — 984F/947A 984F/947A 966F 966F 966F 966F

Finishing — — 341D/ — 341D/ 3XXD*/ 777F/ Trizact 461F 461F

Trizact Trizact Trizact Trizact

stainless steel

Good — — 577F 341D 577F 577F — — 341D 361F

Better 577F 577F 777F — 777F 777F 577F 577F 577F 577F

Best 984F/947A 984F/994F/ 997F 947A 747D/ 947A 984F/ 947A 984F/ 947A 977F 966F 984F 984F

Finishing — — Trizact — Trizact 3XXD*/ 777F/ Trizact 461F/ 461F/

Trizact Trizact Trizact Trizact

Aluminum, brass & bronze

Good 241E 577F — — — — — — 341D 361F

Better 577F 963G 577F — 577F 577F 577F 577F 577F 577F

Best 984F/ 947A 984F/994F/ 997F 947A — 984F/ 947A 984F/ 947A — — — —

Finishing — — 341D/ — 341D/ 3XXD*/ 341D/ 461F 461F 461F

Trizact Trizact Trizact Trizact

Cobalt and Nickel Alloys

Good — — 577F — 577F 577F — — 577F 577F

Better 577F 577F 777F — 777F 777F 577F 577F 777F 777F

Best 984F/ 947A 984F/994F/ 997F 947A — 984F/947A 984F/947A 977F 966F 984F 984F

Finishing — — Trizact — Trizact 3XXD*/ 777F/ Trizact 461F 461F

Trizact Trizact

Titanium

Good — — 461F — 461F 461F — — — 461F

Better 577F 577F 577F — 577F 577F — 577F — 577F

Best 984F 984F/994F/ 997F — — 984F 984F/ — 966F — 966F

Finishing — — 461F — 461F/ 3XXD*/ — Trizact — 461F

Trizact Trizact

*3XXD: Choose from 302D, 332D and 341D depending upon backing flexibility needed for application.

rOLOC DIsCs

™

Material produCt id Mineral type features Metal type GrindinG liGht GrindinG blendinG deburrinG

General purpose grinding, light grinding,

361F Aluminum Oxide blending, and deburring on all metals. All Metals X X X X

Good

461F Silicon Carbide Ideal for grinding glass, titanium Titanium X X X X

and non-ferrous metals.

better 777F Ceramic Aluminum Durable Y wt. Cloth backing; Stainless Steel, X X X X

Oxide Blend Grinding aid. Nickel Alloy

963G Ceramic Abrasive Durable backing. Carbon Steel X X X X

best Durable 2-ply backing; Stainless Steel,

977F Grain Grinding aid. Nickel Alloy X X X X

Precision Shaped Durable 2-ply backing;

Premium 984F All Metals X X X X

Ceramic Grain Grinding aid; fastest cutting

rOLOC FIbre DIsC seLeCTION GuIDe

™

Material produCt id Mineral features Metal type GrindinG liGht GrindinG blendinG deburrinG

Versatile disc for use on a wide variety of metals;

Aluminum

Good 501C Zirconia General purpose grinding, blending and finishing All Metals X X — X

on all metals.

Ceramic Aluminum Excellent for stainless steel;

better 785C Stainless Steel X X — X

Oxide Blend Grinding aid.

Unique single-piece construction that can eliminate

Ceramic button delamination and enhance disc performance;

best 988R Mild Steel X X — X

Abrasive Grain Cut through metal stock to quickly level welds and

take on tough jobs in small areas.

Precision Shaped

Premium 982C Fastest cutting; Longest life All Metals X X X X

Ceramic Grain