Page 1448 - All Industrial Tool Supply | General Catalog

P. 1448

Water & Oil Hardening • DRILL ROD

1445

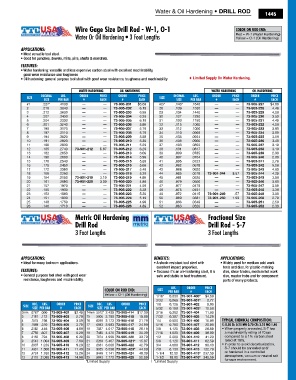

Wire Gage Size Drill Rod - W-1, O-1 COlOR On ROD EnD:

Water Or Oil Hardening • 3 Foot Lengths Red = W-1 (Water Hardening)

Yellow = O-1 (Oil Hardening)

APPLICATIONS:

• Most versatile tool steel.

• Good for punches, dowels, mills, pins, shafts & mandrels.

feATureS:

• Water hardening: versatile and less expensive carbon steel with excellent machinability,

good wear resistance and toughness

• Oil hardening: general purpose tool steel with good wear resistance, toughness and machinability ♦ Limited Supply On Water Hardening.

WaTER HaRDEninG Oil HaRDEninG WaTER HaRDEninG Oil HaRDEninG

DECiMal lbS. ORDER pRiCE ORDER pRiCE DECiMal lbS. ORDER pRiCE ORDER pRiCE

SizE SizE

SizE pER baR # EaCH # EaCH SizE pER baR # EaCH # EaCH

#1 .227" .4130 — — 73-905-201 $6.69 #27 .143" .1640 — — 73-905-227 $4.69

2 .219 .3840 — — 73-905-202 6.19 28 .139 .1550 — — 73-905-228 4.49

3 .212 .3600 — — 73-905-203 6.59 29 .134 .1440 — — 73-905-229 4.09

4 .207 .3430 — — 73-905-204 6.29 30 .127 .1290 — — 73-905-230 3.59

5 .204 .3330 — — 73-905-205 6.19 31 .120 .1150 — — 73-905-231 4.49

6 .201 .3240 — — 73-905-206 5.99 32 .115 .1060 — — 73-905-232 4.09

7 .199 .3170 — — 73-905-207 5.79 33 .112 .1000 — — 73-905-233 3.89

8 .197 .3110 — — 73-905-208 5.79 34 .110 .0969 — — 73-905-234 3.69

9 .194 .3020 — — 73-905-209 5.59 35 .108 .0934 — — 73-905-235 3.59

10 .191 .2920 — — 73-905-210 5.39 36 .106 .0900 — — 73-905-236 3.49

11 .188 .2830 — — 73-905-211 5.29 37 .103 .0850 — — 73-905-237 3.19

12 .185 .2740 73-901-212 $.87 73-905-212 6.29 38 .101 .0817 — — 73-905-238 3.19

13 .182 .2650 — — 73-905-213 6.09 39 .099 .0785 — — 73-905-239 2.99

14 .180 .2600 — — 73-905-214 5.99 40 .097 .0754 — — 73-905-240 2.89

15 .178 .2540 — — 73-905-215 5.89 41 .095 .0723 — — 73-905-241 2.79

16 .175 .2450 — — 73-905-216 5.69 42 .092 .0678 — — 73-905-242 5.09

17 .172 .2380 — — 73-905-217 5.49 43 .088 .0620 — — 73-905-243 4.69

18 .168 .2260 — — 73-905-218 5.29 44 .085 .0578 73-901-244 $.57 73-905-244 4.29

19 .164 .2150 73-901-219 3.19 73-905-219 4.99 45 .081 .0526 — — 73-905-245 3.99

20 .161 .2080 73-901-220 3.09 73-905-220 4.89 46 .079 .0500 — — 73-905-246 3.69

21 .157 .1970 — — 73-905-221 4.59 47 .077 .0479 — — 73-905-247 3.59

22 .155 .1900 — — 73-905-222 5.39 48 .075 .0451 — — 73-905-248 3.39

23 .153 .1880 — — 73-905-223 5.39 49 .072 .0415 73-901-249 .57 73-905-249 3.09

24 .151 .1830 — — 73-905-224 5.19 50 .069 .0381 73-901-250 1.99 73-905-250 2.79

25 .148 .1750 — — 73-905-225 4.99 51 .066 .0349 — — 73-905-251 2.59

26 .146 .1710 — — 73-905-226 4.89 52 .063 .0320 — — 73-905-252 2.39

Metric Oil Hardening Fractional Size

Drill Rod Drill Rod - S-7

3 Foot Lengths 3 Foot Lengths

APPLICATIONS: BeNefITS: APPLICATIONS:

• Ideal for many toolroom applications. • A shock-resistant tool steel with • Widely used for medium cold work

excellent impact properties. tools and dies, for plastic-molding

feATureS: • Because it's an air-hardening steel, it is dies, shear blades, medium hot work

• General purpose tool steel with good wear safe and stable in heat treatment. dies, master hobs and for component

resistance, toughness and machinability. parts of many products.

lbS. ORDER pRiCE

COlOR On ROD EnD: SizE pER baR # EaCH

Yellow = O-1 (Oil Hardening) 1/16" 0.030 73-901-400* $4.59

3/32 0.069 73-901-401* 2.77

DEC. lbS. ORDER pRiCE DEC. lbS. ORDER pRiCE 1/8 0.126 73-901-402 8.09

SizE SizE

SizE pER baR # EaCH SizE pER baR # EaCH 5/32 0.198 73-901-403* 10.59

2mm .0787" .050 73-905-402 $2.49 14mm .5512" 2.430 73-905-414 $17.39 3/16 0.282 73-901-404 11.99

3 .1181 .112 73-905-403 2.79 15 .5906 2.790 73-905-415 19.89 7/32 0.387 73-901-405 14.29

4 .1575 .198 73-905-404 3.09 16 .6299 3.173 73-905-416 21.79 1/4 0.500 73-901-406 16.09 TypiCal CHEMiCal COMpOSiTiOn:

5 .1969 .310 73-905-405 3.79 17 .6693 3.583 73-905-417 24.99 5/16 0.780 73-901-407 20.99 C: 0.50 Si: 0.25 Mn 0.70 CR: 3.25 MO 1.40

6 .2362 .446 73-905-406 4.89 18 .7087 4.017 73-905-418 28.19 3/8 1.120 73-901-408 28.69 • When properly annealed, S-7 has

7 .2756 .607 73-905-407 5.29 19 .7480 4.475 73-905-419 30.39 7/16 1.530 73-901-409 38.99 a machinability rating of 70 (as

8 .3150 .794 73-905-408 6.29 20 .7874 4.959 73-905-420 33.79 1/2 2.000 73-901-410 41.29 compared to a 1% carbon steel

9 .3543 1.004 73-905-409 7.69 21 .8268 5.467 73-905-421* 15.87 5/8 3.120 73-901-411 62.59 rated at 100).

10 .3937 1.239 73-905-410 9.29 22 .8661 6.000 73-905-422 42.79 3/4 4.500 73-901-412 90.19 • In order to avoid decarburization,

11 .4331 1.500 73-905-411 11.49 23 .9055 6.558 73-905-423* 44.09 7/8 6.130 73-901-413 122.79 S-7 should be annealed and/

12 .4724 1.785 73-905-412 13.29 24 .9449 7.141 73-905-424 48.39 1-1/4 12.50 73-901-415* 237.59 or hardened in a controlled

13 .5118 2.095 73-905-413 14.99 25 .9843 7.772 73-905-425 52.59 1-1/2 18.00 73-901-416* 345.59 atmosphere, vacuum or neutral salt

furnace environment.

*Limited Supply. *Limited Supply.