Page 327 - All Industrial Tool Supply | General Catalog

P. 327

2 Flute Single End • END MILLS

325

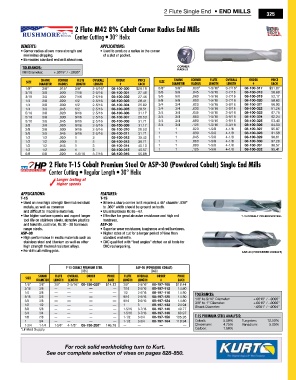

2 Flute M42 8% Cobalt Corner Radius End Mills

Center Cutting • 30° Helix

Benefits: APPLiCAtiOns:

• Corner radius allows more strength and • Used to produce a radius in the corner

minimizes chipping. of a slot or pocket.

• Eliminates standard end mill alterations.

TolERanCEs: CorNEr

raDIuS

Mill Diameter: +.0015" / -.0000"

shank CoRnER FluTE ovERall oRDER PRiCE shank CoRnER FluTE ovERall oRDER PRiCE

sizE sizE

DiaMETER RaDius lEngTh lEngTh # EaCh DiaMETER RaDius lEngTh lEngTh # EaCh

1/8" 3/8" .015" 3/8" 2-5/16" 08-100-300 $29.19 5/8" 5/8" .030" 1-5/16" 3-7/16" 08-100-317 $51.07

3/16 3/8 .020 7/16 2-5/16 08-100-301 27.46 5/8 5/8 .045 1-5/16 3-7/16 08-100-318 56.69

3/16 3/8 .030 7/16 2-5/16 08-100-302 27.46 5/8 5/8 .060 1-5/16 3-7/16 08-100-319 52.17

1/4 3/8 .020 1/2 2-5/16 08-100-303 28.41 5/8 5/8 .090 1-5/16 3-7/16 08-100-320 58.82

1/4 3/8 .030 1/2 2-5/16 08-100-304 25.82 3/4 3/4 .020 1-5/16 3-9/16 08-100-321 66.90

1/4 3/8 .045 1/2 2-5/16 08-100-305 28.51 3/4 3/4 .030 1-5/16 3-9/16 08-100-322 61.26

5/16 3/8 .020 9/16 2-5/16 08-100-306 31.17 3/4 3/4 .045 1-5/16 3-9/16 08-100-323 67.79

5/16 3/8 .030 9/16 2-5/16 08-100-307 28.53 3/4 3/4 .060 1-5/16 3-9/16 08-100-324 62.24

5/16 3/8 .045 9/16 2-5/16 08-100-308 31.71 3/4 3/4 .090 1-5/16 3-9/16 08-100-325 63.40

3/8 3/8 .020 9/16 2-5/16 08-100-309 31.17 3/4 3/4 .125 1-5/16 3-9/16 08-100-326 64.59

3/8 3/8 .030 9/16 2-5/16 08-100-310 28.53 1 1 .020 1-5/8 4-1/8 08-100-327 95.87

3/8 3/8 .045 9/16 2-5/16 08-100-311 31.71 1 1 .030 1-5/8 4-1/8 08-100-328 91.58

1/2 1/2 .020 1 3 08-100-312 39.42 1 1 .045 1-5/8 4-1/8 08-100-329 96.61

1/2 1/2 .030 1 3 08-100-313 39.71 1 1 .060 1-5/8 4-1/8 08-100-330 97.26

1/2 1/2 .045 1 3 08-100-314 40.10 1 1 .090 1-5/8 4-1/8 08-100-331 98.57

1/2 1/2 .060 1 3 08-100-315 40.57 1 1 .125 1-5/8 4-1/8 08-100-332 95.41

5/8 5/8 .020 1-5/16 3-7/16 08-100-316 55.88

2 Flute T-15 Cobalt Premium steel or asP-30 (Powdered Cobalt) single End Mills

Center Cutting • Regular Length • 30° Helix

Longer lasting at

higher speeds

APPLiCAtiOns: feAtures:

T-15 T-15

• Used on new high strength thermal resistant • Where a sharp corner isn't required, a 45° chamfer .030"

metals, as well as common to .060" width should be ground on tooth.

and difficult to machine materials. • Usual hardness Rc 65 - 67.

• Use higher surface speeds and expect longer • Effective for great abrasive resistance and high red T-15 CoBaLT PrEMIuM STEEL

tool life on stainless steels, abrasive plastics hardness.

and bakelite, cast iron, Rc 30 - 50 hardness ASP-30

range steels. • Superior wear resistance, toughness and red hardness.

ASP-30 • Higher rates of cut for a longer period of time than

• High performance in exotic materials such as standard end mills.

stainless steel and titanium as well as other • CNC qualified with “lead angles” etched on all tools for

high strength thermal resistant alloys. CNC resharpening.

• For difficult milling jobs. aSP-30 (PoWDErED CoBaLT)

T-15 CobalT PREMiuM sTEEl asP-30 (PowDERED CobalT)

[D26] [D63]

shank FluTE ovERall oRDER PRiCE FluTE ovERall oRDER PRiCE

sizE

DiaMETER lEngTh lEngTh # EaCh lEngTh lEngTh # EaCh

1/8" 3/8" 3/8" 2-5/16" 08-150-020* $14.13 3/8" 2-5/16" 08-197-108 $18.44

3/16 3/8 — — — — 7/16 2-5/16 08-197-112 14.80

1/4 3/8 — — — — 1/2 2-5/16 08-197-116 14.80 TolERanCEs:

5/16 3/8 — — — — 9/16 2-5/16 08-197-120 14.80 1/8" to 5/16" Diameter: +.0010" / -.0000"

3/8 3/8 — — — — 9/16 2-5/16 08-197-124 14.80 3/8" to 1" Diameter: +.0015" / -.0000"

1/2 1/2 — — — — 1 3 08-197-132 24.94 Shank Diameter: -.0001" / -.0004"

5/8 5/8 — — — — 1-5/16 3-7/16 08-197-140 40.77

3/4 3/4 — — — — 1-5/16 3-7/16 08-197-148 60.97

7/8 7/8 — — — — 1-1/2 3-3/4 08-197-156 105.26 T-15 PREMiuM sTEEl analysis:

1 3/4 — — — — 1-1/2 3-3/4 08-197-164 118.94 Cobalt: 5.00% Tungsten: 12.50%

1-3/4 1-1/4 1-5/8" 4-1/8" 08-150-280* 146.76 — — — — Chromium: 4.75% Vanadium: 5.00%

*Limited Supply. Carbon: 1.50%

For rock solid workholding turn to Kurt.

See our complete selection of vises on pages 828-850.