Page 334 - All Industrial Tool Supply | General Catalog

P. 334

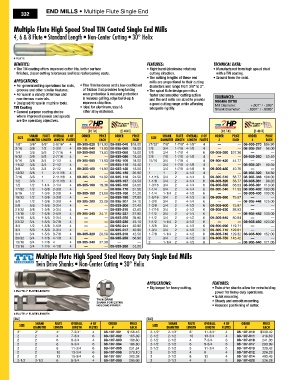

END MILLS • Multiple Flute Single End

332

Multiple Flute High Speed Steel TiN Coated Single End Mills

4, 6 & 8 Flute • Standard Length • Non-Center Cutting • 30° Helix

4 FLUTE

Benefits: feAtures: teChniCAL DAtA:

• The TiN coating offers improved cutter life, better surface • Right hand (clockwise rotation) • Manufactured from high speed steel

finishes, closer cutting tolerances and less resharpening costs. cutting direction. with a TiN coating.

• The cutting lengths of these end • Ground from the solid.

APPLiCAtiOns: mills are proportional to their cutting

• For general milling operations for slots, • Thin film hardness and a low coefficient diameters and range from 3/8" to 2".

grooves and other similar features. of friction that provides long lasting • The spiral flute design permits a

• For use in a variety of ferrous and wear protection & reduced protection faster and smoother cutting action TolEraNCES:

non-ferrous materials. & reduces galling, edge build-up & and the end mills are sized to provide

• Designed for use in machine tools. improves chip flow. a good cutting range while affording Niagara CuTTEr +.001" / -.000"

Mill Diameter:

TiN Coating • Ideal for aluminum, steel & adequate rigidity. Shank Diameter: -.0001" / -.0005"

• General purpose coating choice other alloy materials.

where improved speeds and speeds

are the operating objectives.

[D2 TiN] [S-404T] [D2 TiN] [S-404T]

SHaNk

FluTE ovErall # oF

SHaNk

FluTE ovErall # oF

SizE DiaMETEr lENgTH lENgTH FluTES orDEr PriCE orDEr PriCE SizE DiaMETEr lENgTH lENgTH FluTES orDEr PriCE orDEr PriCE

EaCH

#

EaCH

#

EaCH

#

EaCH

#

1/8" 3/8" 3/8" 2-5/16" 4 09-305-020 $11.93 08-935-040 $18.00 27/32" 7/8" 1-7/8" 4-1/8" 4 — — 08-935-270 $56.90

3/16 3/8 1/2 2-3/8 4 09-305-040 11.93 08-935-060 18.00 7/8 3/4 1-7/8 4-1/8 4 — — 08-935-287 56.00

1/4 3/8 5/8 2-7/16 4 09-305-060 11.93 08-935-080 18.00 7/8 3/4 1-7/8 4 6 09-305-380 $37.30 — —

9/32 3/8 5/8 2-7/16 4 — — 08-935-090 18.40 7/8 7/8 1-7/8 4-1/8 4 — — 08-935-280 53.40

5/16 3/8 3/4 2-1/2 4 09-305-080 11.93 08-935-100 18.00 15/16 3/4 1-7/8 4 4 09-305-420 44.77 — —

11/32 3/8 3/4 2-1/2 4 — — 08-935-110 18.40 1 3/4 1-7/8 4-1/8 4 — — 08-935-321 60.50

3/8 3/8 3/4 2-1/2 4 09-305-100 11.93 08-935-120 18.00 1 3/4 1-7/8 4-1/8 6 09-305-480 40.70 — —

13/32 3/8 1 2-11/16 4 — — 08-935-130 25.60 1 1 2 4-1/2 4 — — 08-935-320 64.30

7/16 3/8 1 2-11/16 4 09-305-120 14.02 08-935-140 24.50 1-1/16 3/4 2 4-1/4 6 09-305-510 58.77 08-935-348 104.00

1/2 3/8 1 2-11/16 4 — — 08-935-167 24.50 1-1/8 3/4 2 4-1/4 6 09-305-520 58.77 08-935-361 94.20

1/2 1/2 1-1/4 3-1/4 4 09-305-160 19.36 08-935-160 24.50 1-3/16 3/4 2 4-1/4 6 09-305-530 66.53 08-935-381 113.00

17/32 1/2 1-3/8 3-3/8 4 — — 08-935-170 31.50 1-1/4 3/4 2 4-1/4 6 09-305-540 71.53 08-935-402 103.00

9/16 1/2 1-3/8 3-3/8 4 09-305-180 21.68 08-935-180 31.20 1-1/4 1-1/4 2 4-1/2 6 — — 08-935-400 100.00

19/32 1/2 1-3/8 3-3/8 4 — — 08-935-190 37.80 1-5/16 3/4 2 4-1/2 6 09-305-590 75.87 — —

5/8 1/2 1-3/8 3-3/8 4 09-305-200 23.09 08-935-207 34.10 1-3/8 3/4 2 4-1/4 6 — — 08-935-448 125.00

5/8 5/8 1-5/8 3-3/4 4 — — 08-935-200 37.40 1-3/8 3/4 2 4-1/2 6 09-305-600 75.87 — —

21/32 5/8 1-5/8 3-3/4 4 — — 08-935-210 42.60 1-7/16 3/4 2 4-1/2 6 09-305-630 88.93 — —

11/16 1/2 1-5/8 3-5/8 4 09-305-240 24.11 08-935-227 37.80 1-1/2 3/4 2 4-1/4 6 — — 08-935-482 133.00

11/16 5/8 1-5/8 3-3/4 4 — — 08-935-220 39.90 1-1/2 3/4 2 4-1/2 6 09-305-640 80.84 — —

23/32 3/4 1-5/8 3-7/8 4 — — 08-935-230 45.10 1-1/2 1-1/4 2 4-1/2 6 — — 08-935-480 123.00

3/4 1/2 1-5/8 3-5/8 4 — — 08-935-241 40.90 1-5/8 3/4 2 4-1/2 6 09-305-690 119.71 — —

3/4 5/8 1-5/8 3-3/4 4 — — 08-935-247 40.90 1-3/4 3/4 2 4-1/2 6 09-305-710 129.81 — —

3/4 3/4 1-5/8 3-7/8 4 09-305-320 28.56 08-935-240 42.50 1-7/8 1-1/4 2 4-1/2 6 09-305-740 129.32 08-935-600 152.00

25/32 3/4 1-7/8 4-1/8 4 — — 08-935-250 56.90 2 3/4 2 4-1/2 8 09-305-750 145.42 — —

13/16 3/4 1-7/8 4 4 09-305-340 37.30 — — 2 1-1/4 2 4-1/2 8 — — 08-935-640 171.00

13/16 3/4 1-7/8 4-1/8 4 — — 08-935-260 53.00

Multiple Flute High Speed Steel Heavy Duty Single End Mills

Twin Drive Shanks • Non-Center Cutting • 30° Helix

APPLiCAtiOns: feAtures:

• Big torque for heavy cutting. • Twin drive shanks allow for extra holding

4 FLUTE 4" FLUTE LEngTh power for heavy duty operations.

• Quick mounting.

Twin drivE • Steady and smooth mounting.

shank For ExTra

hoLding powEr • Accurate positioning of cutter.

6 FLUTE 4" FLUTE LEngTh

[D60] [D60]

SHaNk FluTE ovErall # oF orDEr PriCE SHaNk FluTE ovErall # oF orDEr PriCE

SizE SizE

DiaMETEr lENgTH lENgTH FluTES # EaCH DiaMETEr lENgTH lENgTH FluTES # EaCH

2" 2" 4" 7-3/4" 4 08-107-001 $158.45 2-1/2" 2-1/2" 8" 11-3/4" 4 08-107-010 $330.42

2 2 4 7-3/4 6 08-107-002 165.89 2-1/2 2-1/2 10 13-3/4 4 08-107-011 416.69

2 2 6 9-3/4 4 08-107-003 186.80 2-1/2 2-1/2 4 7-3/4 6 08-107-016 241.06

2 2 6 9-3/4 6 08-107-004 186.80 2-1/2 2-1/2 6 9-3/4 6 08-107-017 293.99

2 2 8 11-3/4 6 08-107-005 231.84 2-1/2 2-1/2 8 11-3/4 6 08-107-018 330.42

2 2 10 13-3/4 6 08-107-006 279.10 3 2-1/2 4 8 4 08-107-012 326.28

2 2 12 15-3/4 6 08-107-007 302.38 3 2-1/2 8 12 4 08-107-014 493.49

2-1/2 2-1/2 6 9-3/4 4 08-107-009 295.09 3 2-1/2 4 8 6 08-107-020 326.28