Page 344 - All Industrial Tool Supply | General Catalog

P. 344

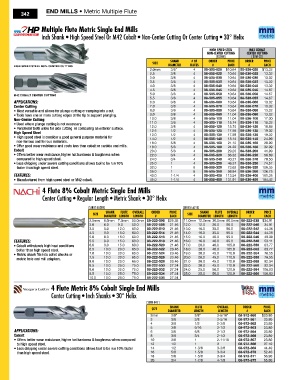

END MILLS • Metric Multiple Flute

342

Multiple Flute Metric Single End Mills

Inch Shank • High Speed Steel Or M42 Cobalt • Non-Center Cutting Or Center Cutting • 30° Helix

high SPEED StEEl M42 CObalt

nOn-CEntEr Cutting CEntEr Cutting

[D2MM] [D2M-CO]

Shank # OF OrDEr PriCE OrDEr PriCE

SizE

HigH Speed Steel NoN-CeNter CuttiNg DiaMEtEr FlutES # EaCh # EaCh

2.0mm 3/8" 4 08-505-020 $10.64 08-536-020 $13.32

2.5 3/8 4 08-505-025 10.64 08-536-025 13.32

3.0 3/8 4 08-505-030 10.64 08-536-030 13.32

3.5 3/8 4 08-505-035 10.64 08-536-035 13.32

4.0 3/8 4 08-505-040 10.64 08-536-040 13.32

4.5 3/8 4 08-505-045 10.64 08-536-045 14.67

5.0 3/8 4 08-505-050 10.64 08-536-050 14.67

M42 Cobalt CeNter CuttiNg

5.5 3/8 4 08-505-055 10.64 08-536-055 14.67

APPLICATIONS: 6.0 3/8 4 08-505-060 10.64 08-536-060 13.32

Center Cutting 7.0 3/8 4 08-505-070 10.64 08-536-070 13.32

• Most versatile and allows for plunge cutting or ramping into a cut. 8.0 3/8 4 08-505-080 10.64 08-536-080 13.32

• Tools have one or more cutting edges at the tip to support plunging. 9.0 3/8 4 08-505-090 11.04 08-536-090 13.32

Non-Center Cutting 10.0 3/8 4 08-505-100 11.04 08-536-100 17.30

• Used where plunge cutting is not necessary. 11.0 3/8 4 08-505-110 15.74 08-536-110 18.32

• Peripheral teeth allow for side cutting or contouring an exterior surface. 12.0 3/8 4 08-505-120 15.74 08-536-120 18.89

High Speed Steel 12.5 1/2 4 4 08-505-125 17.59 08-536-125 19.32

13.0

17.59

08-536-130

19.32

1/2

08-505-130

• High speed steel is consider a good general purpose material for 14.0 1/2 4 08-505-140 18.14 08-536-140 24.99

non-ferrous and ferrous materials. 16.0 5/8 4 08-505-160 21.12 08-536-160 28.99

• Offer good wear resistance and costs less than cobalt or carbide end mills. 18.0 5/8 4 08-505-180 24.22 08-536-180 32.99

Cobalt 20.0 5/8 4 08-505-200 29.20 08-536-200 41.99

• Offers better wear resistance, higher hot hardness & toughness when 22.0 3/4 4 08-505-220 36.32 08-536-220 56.69

compared to high speed steel. 24.0 3/4 4 08-505-240 40.27 08-536-240 70.50

• Less chipping under severe cutting conditions allows tool to be run 10% 25.0 1 4 08-505-250 46.37 08-536-250 74.57

faster than high speed steel. 32.0 1 6 08-505-320 73.62 08-536-320 106.35

36.0 1 6 08-505-360 98.84 08-536-360 126.75

FeATureS: 40.0 1-1/4 4 08-505-400 113.54 08-536-400 161.35

• Manufactured from high speed steel or M42 cobalt. 45.0 1-1/4 4 08-505-450 131.91 08-536-450 184.42

4 Flute 8% Cobalt Metric Single End Mills

Center Cutting • Regular Length • Metric Shank • 30° Helix

[SeRIeS L6210] [SeRIeS L6210]

Shank FlutE OvErall OrDEr PriCE Shank FlutE OvErall OrDEr PriCE

SizE SizE

DiaMEtEr lEngth lEngth # EaCh DiaMEtEr lEngth lEngth # EaCh

2.5mm 6.0mm 7.0mm 50.0mm 08-222-506 $25.35 11.0mm 12.0mm 30.0mm 80.0mm 08-222-538 $34.91

3.0 6.0 9.0 50.0 08-222-508 21.46 12.0 12.0 30.0 80.0 08-222-540 34.91

3.5 8.0 12.0 60.0 08-222-510 21.46 13.0 16.0 35.0 90.0 08-222-542 44.36

4.5 8.0 15.0 60.0 08-222-514 21.46 14.0 16.0 35.0 90.0 08-222-544 44.36

5.0 8.0 15.0 60.0 08-222-516 21.46 15.0 16.0 40.0 95.0 08-222-546 49.39

FeATureS: 5.5 8.0 15.0 60.0 08-222-518 21.46 16.0 16.0 40.0 95.0 08-222-548 53.11

• Cobalt withstands high heat conditions 6.0 8.0 15.0 60.0 08-222-520 21.46 17.0 20.0 40.0 105.0 08-222-550 63.77

better than high speed steel. 6.5 10.0 20.0 65.0 08-222-522 23.46 18.0 20.0 40.0 105.0 08-222-552 63.77

• Metric shank fits into collet chucks or 7.0 10.0 20.0 65.0 08-222-524 23.46 19.0 20.0 45.0 110.0 08-222-554 76.55

metric hole end mill adapters. 7.5 10.0 20.0 65.0 08-222-526 23.46 20.0 20.0 45.0 110.0 08-222-556 76.55

8.0 10.0 20.0 65.0 08-222-528 23.46 21.0 20.0 45.0 110.0 08-222-558 92.34

8.5 10.0 25.0 75.0 08-222-530 27.24 22.0 20.0 45.0 110.0 08-222-560 92.34

9.0 10.0 25.0 75.0 08-222-532 27.24 24.0 25.0 50.0 120.0 08-222-564 106.83

9.5 10.0 25.0 75.0 08-222-534 27.24 25.0 25.0 50.0 120.0 08-222-566 106.83

10.0 10.0 25.0 75.0 08-222-536 27.24

4 Flute Metric 8% Cobalt Single End Mills

Center Cutting • Inch Shanks • 30° Helix

[SMM-845]

Shank FlutE OvErall OrDEr PriCE

SizE

DiaMEtEr lEngth lEngth # EaCh

2mm 3/8" 3/8" 2-5/16" 08-972-860 $23.80

3 3/8 3/8 2-5/16 08-972-861 23.80

4 3/8 1/2 2-3/8 08-972-862 23.80

5 3/8 9/16 2-1/2 08-972-863 23.80

APPLICATIONS: 6 3/8 5/8 2-1/2 08-972-864 23.80

Cobalt 8 3/8 3/4 2-1/2 08-972-866 23.80

• Offers better wear resistance, higher hot hardness & toughness when compared 10 3/8 1 2-11/16 08-972-867 23.80

to high speed steel. 12 1/2 1 3 08-972-868 37.10

• Less chipping under severe cutting conditions allows tool to be run 10% faster 14 1/2 1-3/8 3-3/8 08-972-869 44.40

than high speed steel. 16 5/8 1-5/8 3-3/4 08-972-870 52.40

18 5/8 1-5/8 3-3/4 08-972-871 56.90

20 3/4 1-7/8 4-1/8 08-972-872 65.80