Page 537 - All Industrial Tool Supply | General Catalog

P. 537

Turning Inserts • LAMINA

535

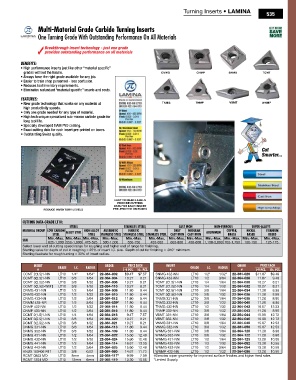

Multi-Material Grade Carbide Turning Inserts

One Turning Grade With Outstanding Performance On All Materials

Breakthrough insert technology - just one grade

provides outstanding performance on all materials

Benefits:

• High performance inserts just like other “material specific”

grades without the hassle. CNMG CNMp SNMG TCMT

• Always have the right grade available for any job.

• Easier to train shop personnel - less confusion.

• Reduces tool inventory requirements.

• Eliminates redundant “material specific” inserts and costs.

features:

• New grade technology that works on any material at TNMG TNMp VBMT WNMp

high productivity speeds.

• Only one grade needed for any type of material.

• High tech unique specialized sub-micron carbide grade for

long tool life.

• Specially developed TiAlN PVD coating.

• Exact cutting data for each insert pre-printed on boxes.

• Outstanding Swiss quality.

...

EASY TO READ LABELS

pROVIDE CUTTING

DATA fOR EACh INSERT

REDUCE INVENTORY LEVELS pRE-pRINTED ON BOxES

CuTTInG DaTa-GraDe LT10:

STeeLS STaInLeSS STeeLS CaST Iron non-FerrouS Super-aLLoyS

MaTerIaL Group Low Carbon aLLoy STeeL HIGH aLLoy auSTenITIC FerrITIC pH Grey noDuLar aLuMInuM Copper, nICkeL TITanIuM

STeeL STeeL STaInLeSS STeeL STaInLeSS STeeL STaInLeSS STeeL CaST Iron CaST Iron braSS baSeD baSeD

SFM Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max. Min.-Max.

825-1,300 550-1,000 475-525 500-1,000 550-750 450-650 600-850 450-600 1,100-3,000 700-1,700 100-150 125-175

Select lower end of cutting speed range for roughing and higher end of range for finishing.

Starting value for depth of cut in roughing = 25% of insert I.C. size. Depth of cut for finishing = .010" minimum.

Starting feedrate for rough turning = 33% of insert radius.

InSerT GraDe I.C. raDIuS orDer ___prICe eaCH___ InSerT GraDe I.C. raDIuS orDer ___prICe eaCH___

# # 1-9 pCS. 10+ pCS. # # 1-9 pCS. 10+ pCS.

CCMT 2(1.5)1-NN LT10 1/4" 1/64" 22-364-002 $9.47 $7.57 SNMG 432-NN LT10 1/2" 1/32" 22-364-026 $11.87 $9.49

CCMT 3(2.5)1-NN LT10 3/8 1/64 22-364-004 10.27 8.21 SNMG 433-NN LT10 1/2 3/64 22-364-028 11.87 9.49

CCMT 3(2.5)2-NN LT10 3/8 1/32 22-364-006 10.27 8.21 TCMT 2(1.5)1-NN LT10 1/4 1/64 22-364-030 10.27 8.21

CCMT 3(2.5)2-WM† LT10 3/8 1/32 22-364-110 10.27 8.21 TCMT 2(1.5)2-NN LT10 1/4 1/32 22-364-032 10.27 8.21

CNMG 431-NN LT10 1/2 1/64 22-364-008 11.80 9.44 TCMT 3(2.5)1-NN LT10 3/8 1/64 22-364-034 11.20 8.96

CNMG 432-NN LT10 1/2 1/32 22-364-010 11.80 9.44 TCMT 3(2.5)2-NN LT10 3/8 1/32 22-364-036 11.20 8.96

CNMG 433-NN LT10 1/2 3/64 22-364-012 11.80 9.44 TNMG 331-NN LT10 3/8 1/64 22-364-038 11.20 8.96

CNMM 433-NR LT10 1/2 3/64 22-364-059* 11.80 9.44 TNMG 332-NN LT10 3/8 1/32 22-364-040 11.20 8.96

CNMP 432 NN LT10 1/2 1/32 22-364-014 11.80 9.44 TNMG 432-NN LT10 1/2 1/32 22-364-042 16.67 13.33

CNMP 433-NN LT10 1/2 3/64 22-364-016 11.80 9.44 TNMP 332-NN LT10 3/8 1/32 22-364-043 11.20 8.96

DCMT 2(1.5)1-NN LT10 1/4 1/64 22-364-018 9.47 7.57 VBMT 331-NN LT10 3/8 1/64 22-364-044 15.90 12.72

DCMT 3(2.5)1-NN LT10 3/8 1/64 22-364-020 10.27 8.21 VBMT 332-NN LT10 3/8 1/32 22-364-046 15.90 12.72

DCMT 3(2.5)2-NN LT10 3/8 1/32 22-364-021 10.27 8.21 VNMG 331-NN LT10 3/8 1/64 22-364-048 15.67 12.53

DNMG 331-NN LT10 3/8 1/64 22-364-113 11.80 9.44 VNMG 332-NN LT10 3/8 1/32 22-364-050 15.67 12.53

DNMG 332-NN LT10 3/8 1/32 22-364-109 11.80 9.44 WNMG 331-NN LT10 3/8 1/64 22-364-120 11.20 8.96

DNMG 431-NN LT10 1/2 1/64 22-364-022 15.60 12.48 WNMG 332-NN LT10 3/8 1/32 22-364-122 11.20 8.96

DNMG 432-NN LT10 1/2 1/32 22-364-024 15.60 12.48 WNMG 431-NN LT10 1/2 1/64 22-364-123 13.20 10.56

DNMG 441-NN LT10 1/2 1/64 22-364-114 16.67 13.33 WNMG 432-NN LT10 1/2 1/32 22-364-052 13.20 10.56

DNMG 443-NN LT10 1/2 3/64 22-364-025 15.60 12.48 WNMG 433-NN LT10 1/2 3/64 22-364-054 13.20 10.56

KNUX 160405 R11 LT10 3/8 0.02 22-364-060 14.67 11.73 WNMP 432-NN LT10 1/2 1/32 22-364-056 13.20 10.56

RCMT 0803 MO LT10 8mm 4mm 22-364-117* 9.99 7.99 †Denotes wiper geometry for improved surface finishes and higher feed rates.

RCMT 1204 MO LT10 12mm 6mm 22-364-119 13.20 10.56 *Limited Supply.