Page 539 - All Industrial Tool Supply | General Catalog

P. 539

Technical Turning • T&O

537

Carbide Grades

Famous Brand Performance Without The Famous Brand Price

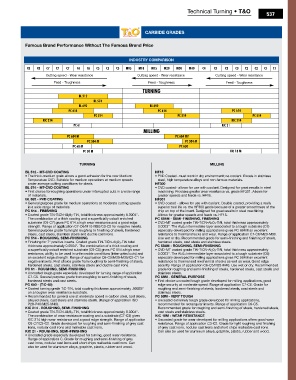

INDUSTRY COMPARISON

C8 C8 C7 C7 C7 C6 C6 C5 C5 C5 M05 M10 M15 M20 M30 M40 C4 C3 C3 C3 C2 C2 C1 C1

Cutting speed - Wear resistance Cutting speed - Wear resistance Cutting speed - Wear resistance

Feed - Toughness Feed - Toughness Feed - Toughness

TURNING

BL 512

BL 574

BL 692 BL 692

PC 614 PC 614 PC 614

PC 514 PC 514 PC 514

KIC 214 KIC 214

PC 61 KIC 21

MILLING

PC 684 M PC 684 MT

PC 584 M PC 584 M

PC 68 M PC 650

PC 58 M KIC 18 M

Turning MiLLing

BL 512 - MT-CVD COATing HF15

• The thick-medium grain allows a good adhesion for the new Medium • PVD Coated -must work in dry environment; no coolant. Excels in stainless

Temperature CVD. Suitable for medium operations at medium speeds steel, high temperature alloys and non-ferrous materials.

under average cutting conditions for steels. HF300

BL 574 - MT-CVD COATing • CVD coated- allows for use with coolant. Designed for great results in steel

• First choice for roughing operations under interrupted cuts in a wide range machining. Provides greater wear resistance vs. grade HF301. Allows for

of materials. greater speeds and feeds vs. HF15.

BL 692 - PVD COATing HF301

• General purpose grade for medium operations at moderate cutting speeds • CVD coated - allows for use with coolant. Double coated, providing a really

in a wide range of materials. superior tool life vs. the HF300 grade because of a greater smoothness of the

PC 614 - FiniSHing chip on top of the insert. Designed for great results in steel machining.

• Coated grade TiN-TiCN-Al203-TiN, total thickness approximately 0.0004". Allows for greater speeds and feeds vs. HF15.

The combination of a thick coating and a superficially cobalt enriched PC 684M - SEMi-FiniSHing, FiniSHing

substrate (C6-C7) gives PC 614 a high wear resistance and a good edge • CVD-MT coated grade TiN-TiCN-Al203-TiN, total thickness approximately

strength. Range of application C7-C6/M10-M30/C3-C2 for negative inserts. 0.0003". The Al203 intermediate layer associated to a tough substrate (C7)

General purpose grade from light roughing to finishing of steels, hardened especially developed for milling applications gives PC 684M an excellent

steels, cast steels, stainless steels and ductile cast irons. resistance to thermal shocks and wear. Range of application C7-C6/M20-M30.

PC 514 - rOugHing, SEMi-FiniSHing Use wet or dry. Recommended grade for semi-finishing and finishing of steels,

• Finishing for 7° positive inserts. Coated grade TiN-TiCN-Al203-TiN total hardened steels, cast steels and stainless steels.

thickness approximately 0.0004". The combination of a thick coating and PC 584M - rOugHing, SEMi-FiniSHing

a superficially cobalt enriched substrate (C6-C5) gives PC 514 a high wear • CVD-MT coated grade TiN-TiCN-Al203-TiN, total thickness approximately

resistance, ability to be used in unfavorable conditions (interrupted cuts) and 0.0003". The Al203 intermediate layer associated to a tough substrate (C6)

an excellent edge strength. Range of application C6-C5/M20-M35/C2-C1 for especially developed for milling applications gives PC 584M an excellent

negative inserts. First choice grade from roughing to semi-finishing of steels, resistance to thermal and mechanical shocks as well as wear. Good edge

hardened steels, cast steels, stainless steels and ductile cast irons. security. Range of application C6-C5/M25-M40. Use wet or dry. Recommended

PC 61 - rOugHing, SEMi-FiniSHing grade for roughing and semi-finishing of steels, hardened steels, cast steels and

• Uncoated tough grade especially developed for turning range of application stainless steels.

C7-C5. General purpose grade from roughing to semi-finishing of steels, PC 68M - gEnErAL PurPOSE

hardened steels and cast steels. • First choice uncoated tough grade developed for milling applications, good

PC 650 - (TiC-65) edge security at moderate speed. Range of application C7-C6. Grade for

• Coated turning grade TiC-TiN, total coating thickness approximately .00025" roughing and semi-finishing of steels, hardened steels, cast steels and

on a tougher wear resistance substrate. stainless steels.

• Recommended for general use at moderate speed in carbon steel, tool steels, PC 58M - VErY TOugH

alloyed steels, cast steels and stainless steels. (Range of application ISO • Uncoated extremely tough grade developed for milling applications,

P20-P40/M25-M40). recommended for rectangular inserts. Range of application C6-C5.

KiC 214 - rOugHing, SEMi-FiniSHing Recommended grade for roughing and semi-finishing of steels, hardened steels,

• Coated grade TiN-TiCN-Al203-TiN, total thickness approximately 0.0004". cast steels and stainless steels.

The combination of wear resistance coating and a substrate (C7-C3) gives KiC 18M - WEAr rESiSTAnCE

KIC 214 high wear resistance and a good edge strength. Range of application • Uncoated grade for wear developed for milling applications offers good wear

C8-C7/C3-C2. Grade developed for roughing and semi-finishing of grey cast resistance. Range of application C3-C2. Grade for light roughing and finishing

irons, nodular cast irons and malleable cast irons. of grey cast irons, nodular cast irons and short chips malleable cast irons.

KiC 21 - rOugHing, SEMi-FiniSHing Can also be used for aluminum alloys, graphite, plastic, rubber and wood.

• Uncoated grade especially developed for turning, good wear resistance.

Range of application C. Grade for roughing and semi-finishing of grey

cast irons, nodular cast irons and short chips malleable cast irons. Can

also be used for aluminum alloys, graphite, plastic, rubber and wood.