Page 544 - All Industrial Tool Supply | General Catalog

P. 544

T&O • Grooving, Parting & Forming - Holder, Sets, & Inserts

542

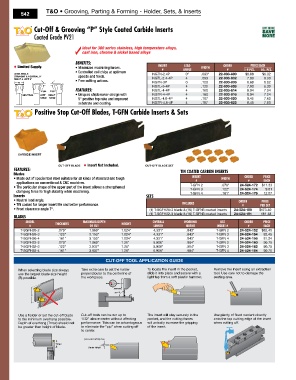

Cut-Off & Grooving “P” Style Coated Carbide Inserts

Coated Grade PV21

Ideal for 300 series stainless, high temperature alloys,

cast iron, chrome & nickel based alloys

Benefits:

♦ Limited Supply. • Minimizes machining forces. INSerT Lead WIdTh Order ____PrICe eaCh____

• Controlled coil chips at optimum # aNGLe # 1-9 PCS. 10+ PCS.

LEAD ANGLE: NGTN-2.4P 0° .093" 22-003-800 $6.68 $6.02

STRAIGHT & NEUTRAL 0° speeds and feeds.

RIGHT & LEFT 8° • Free cutting actions. NGTL-2.4-4P 4 0 .093 22-003-802 7.00 6.30

.120

22-003-806

6.68

6.02

NGTN-3P

NGTL-3-4P 4 .120 22-003-808 7.00 6.30

features: NGTL-4-4P 4 .160 22-003-814 8.04 7.24

NEUTRAL LEFT RIGHT • Uniques chipbreaker design with NGTR-4-4P 4 .160 22-003-816 8.04 7.24

HAND HAND 5° positive top rake and improved NGTL-4.8-4P 4 .187 22-003-820 8.45 7.60

substrate and coating. NGTR-4.8-4P 4 .187 22-003-822 8.45 7.60

Positive Stop Cut-Off Blades, T-GFN Carbide Inserts & Sets

CarBide insert

Cut-Off Blade ♦ Insert Not Included. Cut-Off Blade set

features: TiN COaTed CarBIde INSerTS

Blades

• Made out of special tool steel suitable for all kinds of standard and tough INSerT WIdTh Order PrICe

#

eaCh

#

applications on conventional & CNC machines.

• The particular shape of the upper part of the insert allows a strengthened T-GFN 2 .079" 24-524-172 $11.33

24-524-174

.122"

9.61

T-GFN 3

clamping force for high stability while machining. 24-524-176

Inserts SeTS T-GFN 4 .161" 12.07

• Neutral lead angle. Order PrICe

• TiN coated for longer insert life and better performance. INCLudeS # Per SeT

• Front clearance angle 7°. (1) T-SGFH26-3 blade & (10) T-GFN3 coated inserts 24-524-180 $173.40

(1) T-SGFH32-3 blade & (10) T-GFN3 coated inserts 24-524-181 181.48

BLadeS

MOdeL ThICkNeSS MaxIMuM dePTh heIGhT OveraLL WOrkING uSe Order PrICe

# OF CuT LeNGTh heIGhT INSerT # # eaCh

T-SGFH26-2 .079" 1.969" 1.024" 4.331" .843" T-GFN 2 24-524-152 $82.45

T-SGFH26-3 .122" 3.150" 1.024" 4.331" .843" T-GFN 3 24-524-154 82.45

T-SGFH26-4 .161" 3.150" 1.024" 4.331" .843" T-GFN 4 24-524-156 81.24

T-SGFH32-2 .079" 1.969" 1.26" 5.906" .984" T-GFN 2 24-524-160 90.75

T-SGFH32-3 .122" 3.937" 1.26" 5.906" .984" T-GFN 3 24-524-162 90.75

T-SGFH32-4 .161" 3.937" 1.26" 5.906" .984" T-GFN 4 24-524-164 90.75

Cut-Off tOOl appliCatiOn Guide

When selecting blade size always Take extra care to set the holder To locate the insert in the pocket, Remove the insert using an extraction

use the largest blade size height perpendicular to the centerline of slide it into place and secure with a tool. Use care not to damage the

(B) possible. the workpiece. light tap from a soft plastic hammer. seating area.

Use a holder or set the cut-off blade Cut-off tools can be run up to The insert will stay securely in the Use plenty of flood coolant directly

to the minimum overhang possible. 1/32" above center without affecting pocket, and the cutting forces onto the top cutting edge of the insert

Depth of overhang (Tmax) should not performance. This can be advantageous will actually increase the gripping when cutting off.

be greater than height of blade. to eliminate the “pip” when cutting off of the insert.

to center.