Page 779 - All Industrial Tool Supply | General Catalog

P. 779

Chuck Keys • DRILLING

777

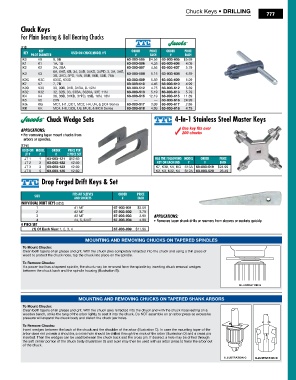

Chuck Keys

For Plain Bearing & Ball Bearing Chucks

[Y10]

Key

Key PIlot DIaMeter USeD on ChUCK MoDel #'S orDer PrICe orDer PrICe

eaCh

#

#

eaCh

K0 K0 0, 0B 63-003-505 $4.55 63-003-605 $5.69

K1 K1 1A, 1B 63-003-506 4.35 63-003-606 4.09

K2 K2 2A, 2BA 63-003-507 4.55 63-003-607 5.79

6A, 6AE, 6B, 34, 34B, 34KD, 34PD, 3, 3A, 3AE,

K3 K3 63-003-508 5.15 63-003-608 6.89

3B, 3KD, 3PD, 14N, 55B, 56B, 58B, 75A

K3C K3C 633C, 633D 63-003-509 5.59 63-003-609 8.29

K7 K7 7, 7B 63-003-510 4.45 63-003-610 4.99

K30 K30 30, 30B, 31B, 31BA, 8-1/2N 63-003-512 4.75 63-003-612 5.39

K32 K32 32, 32B, 33, 33BA, 3326A, 33F, 11N 63-003-513 5.19 63-003-613 5.79

K4 K4 36, 36B, 37KD, 37PD, 59B, 16N, 18N 63-003-515 12.19 63-003-615 11.39

K5 K5 20N — — 63-003-616 24.99

KG KG MC1, H1, DC1, MC2, H4, U4, & DC4 Series 63-003-517 3.09 63-003-617 2.89

KK KK MC4, H8, DC8, U8, MU8, & MC8 Series 63-003-518 4.99 63-003-618 4.79

Chuck Wedge Sets 4-In-1 Stainless Steel Master Keys

APPLICATIONS: One key fits over

200 chucks

• For removing taper mount chucks from

arbors or spindles.

[12-W]

USeD on MoDel orDer PrICe Per

Jt # # # 2 PIeCe Set

JT 1 1 63-003-121 $12.69 haS the FolloWIng MoDel orDer PrICe

JT 2 2 63-003-122 12.69 Key on eaCh enD # # eaCh

JT 3 3 63-003-123 12.69 K7, K30, KK, KG S13A 63-003-519 $24.99

JT 6 6 63-003-126 12.69 K2, K3, K32, K4 S12A 63-003-520 26.49

Drop Forged Drift Keys & Set

SIze FItS Mt SleeveS orDer PrICe

eaCh

#

anD SoCKetS

InDIvIDUal DrIFt KeyS [A25C]

1 #1 MT 67-003-001 $3.59

2 #2 MT 67-003-002 3.79

3 #3 MT 67-003-003 3.99 APPLICATIONS:

4 #4, 5, 6 MT 67-003-004 4.99 • Removes taper shank drills or reamers from sleeves or sockets quickly.

4 PIeCe Set

(1) of each size: 1, 2, 3, 4 67-003-009 $11.99

MouNtING AND ReMovING ChuCks oN tApeReD spINDLes

to Mount Chucks:

Clean both tapers of all grease and grit. With the chuck jaws completely retracted into the chuck and using a thin piece of

wood to protect the chuck nose, tap the chuck into place on the spindle.

to Remove Chucks:

If a power tool has a tapered spindle, the chuck may be removed from the spindle by inserting chuck removal wedges

between the chuck back and the spindle housing (Illustration B).

MouNtING AND ReMovING ChuCks oN tApeReD shANk ARboRs

to Mount Chucks:

Clean both tapers of all grease and grit. With the chuck jaws retracted into the chuck and with the chuck nose resting on a

wooden bench, strike the tang of the arbor lightly to seat it into the chuck. Do NOT assemble on an arbor press as excessive

pressure will expand the chuck body and distort the chuck jaw holes.

to Remove Chucks:

Insert wedges between the back of the chuck and the shoulder of the arbor (Illustration C). In case the mounting taper of the

arbor does not provide a shoulder, a cross hole should be drilled through the neck of the arbor (Illustration D) and a cross pin

inserted. Then the wedges can be used between the chuck back and the cross pin. If desired, a hole may be drilled through

the soft center portion of the chuck body (Illustration D) and a pin may then be used with an arbor press to force the arbor out

of the chuck.