Page 1486 - Ceratizit Catalog

P. 1486

Technical information

F489

Application of deep hole twist drills 16xØ and greater

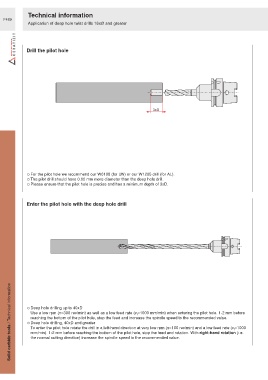

Drill the pilot hole

3xD

○ For the pilot hole we recommend our W0108 (for UN) or our W1205 drill (for AL).

○ The pilot drill should have 0.02 mm more diameter than the deep hole drill.

○ Please ensure that the pilot hole is precise and has a minimum depth of 3xD.

Enter the pilot hole with the deep hole drill

Solid carbide tools / Technical information ○ Deep hole drilling up to 40xD f f

Use a low rpm (n=300 rev/min) as well as a low feed rate (v =1000 mm/min) when entering the pilot hole. 1-2 mm before

reaching the bottom of the pilot hole, stop the feed and increase the spindle speed to the recommended value.

○ Deep hole drilling, 40xD and greater

To enter the pilot hole rotate the drill in a left-hand direction at very low rpm (n=100 rev/min) and a low feed rate (v =1000

mm/min). 1-2 mm before reaching the bottom of the pilot hole, stop the feed and rotation. With right-hand rotation (i.e.

the normal cutting direction) increase the spindle speed to the recommended value.