Page 1488 - Ceratizit Catalog

P. 1488

Technical information

F491

Application of deep hole twist drills 16xØ and greater

Please note:

○ Under unfavourable application conditions, starting from drilling depth 30xØ the swarf must be removed every 3xØ.

The movement to evacuate the swarf (retraction) should take place at the depth of the pilot hole.

○ When the drill exits, and also when through holes are produced in transverse holes the feed rate has to be reduced by 50%

due to the risk of edge chipping.

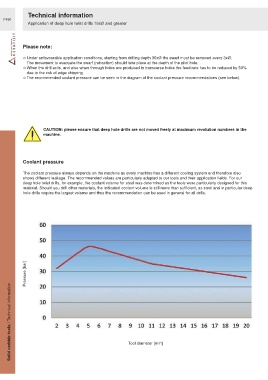

○ The recommended coolant pressure can be seen in the diagram of the coolant pressure recommendations (see below).

CAUTION: please ensure that deep hole drills are not moved freely at maximum revolution numbers in the

machine.

Coolant pressure

The coolant pressure always depends on the machine as every machine has a different cooling system and therefore also

shows different leakage. The recommended values are particularly adapted to our tools and their application fields. For our

deep hole twist drills, for example, the coolant volume for steel was determined as the tools were particularly designed for this

material. Should you drill other materials, the indicated coolant volume is still more than sufficient, as steel and in particular deep

hole drills require the largest volume and thus the recommendation can be used in general for all drills.

Pressure [bar]

Solid carbide tools / Technical information Tool diameter [mm]