Page 1492 - Ceratizit Catalog

P. 1492

Technical information

F495

Application data - reaming

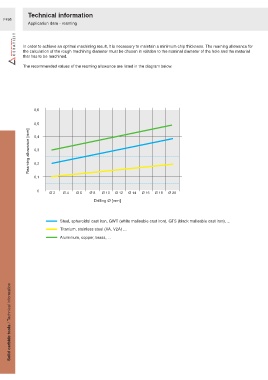

In order to achieve an optimal machining result, it is necessary to maintain a minimum chip thickness. The reaming allowance for

the calculation of the rough machining diameter must be chosen in relation to the nominal diameter of the hole and the material

that has to be machined.

The recommended values of the reaming allowance are listed in the diagram below.

0,6

0,5

Reaming allowance [mm] 0,3

0,4

0,2

0,1

0

Ø 2 Ø 4 Ø 6 Ø 8 Ø 10 Ø 12 Ø 14 Ø 16 Ø 18 Ø 20

Drilling Ø [mm]

Steel, spheroidal cast iron, GWT (white malleable cast iron), GTS (black malleable cast iron), ...

Titanium, stainless steel (VA, V2A) ...

Aluminium, copper, brass, ...

Solid carbide tools / Technical information