Page 30 - Ceratizit Catalog

P. 30

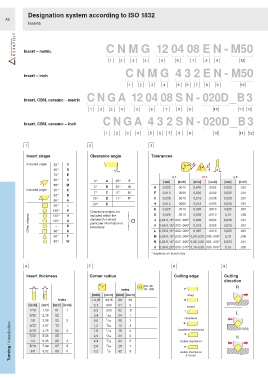

Designation system according to ISO 1832

A9

Inserts

CNMG 12 04 08EN- M50

Insert – metric

1 2 3 4 5 6 7 8 9 13

CNMG 432EN - M50

Insert – inch

1 2 3 4 5 6 7 8 9 13

C N GA 12 04 08SN- 020D_B3

Insert, CBN, ceramic – metric

1 2 3 4 5 6 7 8 9 10 11 12

C N GA 432 SN- 020D_B3

Insert, CBN, ceramic – inch

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3

Insert shape Clearance angle Tolerances

Included angle 35° V d m d m

55° D d m s

75° E

d ± m ± s ±

80° C 3° A 25° F [mm] [inch] [mm] [inch] [mm] [inch]

86° M

5° B 30° G A 0,025 .0010 0,005 .0002 0,025 .001

Included angle 55° K

7° C 0° N F 0,013 .0005 0,005 .0002 0,025 .001

82° B

15° D 11° P C 0,025 .0010 0,013 .0005 0,025 .001

85° A

20° E H 0,013 .0005 0,013 .0005 0,025 .001

90° L

108° H P Clearance angles not E 0,025 .0010 0,025 .0010 0,025 .001

.005

0,025

.0010

0,025

0,13

.0010

G

Other shapes 135° O standard for which O K 0,05-0,15* .002-.006* 0,005 .0002 0,025 .001

included within the

120°

J

0,05-0,15* .002-.006*

particular information is

.0005

0,025

0,013

.001

R

–

necessary

90°

0,13

.005

M 0,05-0,15* .002-.006* 0,05-0,20 .003-.008*

60° S T L 0,05-0,15* .002-.006* 0,025 .0010 0,025 .001

80° W N 0,05-0,15* .002-.006* 0,05-0,20 .003-.008* 0,025 .001

U 0,08-0,25* .003-.010* 0,13-0,38 .005-.015* 0,13 .005

* depends on insert size

6 7 8 9

Insert thickness Corner radius Cutting edge Cutting

direction

F F

F

s s s s r RN 00 F F

Index RC MO F

[mm] [inch] [mm] [inch] E E sharp

E

Index ≤ 0,05 .0015 00 X0 E E

E

[inch] [mm] [mm] [inch] 0,1 .004 01 0

honed

T T

1/16 1,59 01 1 0,2 .008 02 .5 T

T T

3/32 2,38 02 0,4 1 /64 04 1 T

chamfered

1/8 3,18 03 2 3 0,8 1 3 1 /32 08 2 3 4 chamfered and honed

S S

Turning / Introduction 7/32 5,56 05 4 5 6 2,0 5 3 7 1 /16 20 5 6 7 8 double chamfered N

S

S

1,2

T3

5/32

12

3,97

S

/64

S

1,6

04

16

4,76

3/16

K K

/64

K

K

K

1/4

06

24

2,4

K

6,35

/32

5/16

28

7,94

07

2,8

/64

P P

P

P

3/8

09

9,52

P

32

3,2

/8

double chamfered

P

& honed