Page 553 - Ceratizit Catalog

P. 553

MaxiMill 260 system

B226

Assembly procedures

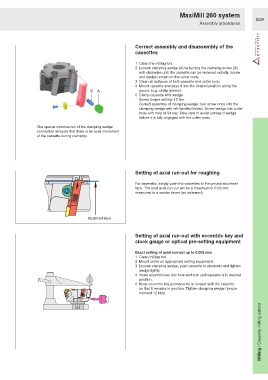

Correct assembly and disassembly of the

cassettes

1 Clean the milling tool.

2 Loosen clamping wedge (A) by turning the clamping screw (B)

anti-clockwise until the cassette can be removed radially. Screw

and wedge remain on the cutter body.

3 Clean all surfaces of both cassette and cutter body.

4 Mount cassette and ease it into the desired position along the

B A groove (e.g. circlip groove).

5 Clamp cassette with wedge.

Screw torque setting: 12 Nm.

Correct assembly of clamping wedge: turn screw once into the

clamping wedge with left-handed thread. Screw wedge into cutter

body with help of S4 key. Take care to avoid turning of wedge

before it is fully engaged with the cutter body.

The special construction of the clamping wedge

connection ensures that there is no axial movement

of the cassette during clamping.

Setting of axial run-out for roughing

For assembly, simply push the cassettes to the ground abutment

face. The total axial run-out will be a maximum of 0.03 mm

measured to a master insert (as delivered).

Abutment face

Setting of axial run-out with eccentric key and

clock gauge or optical pre-setting equipment

Exact setting of axial run-out up to 0.002 mm

1 Clean milling tool.

2 Mount cutter on appropriate setting equipment.

3 Loosen clamping wedge, push cassette to abutment and tighten

wedge lightly.

4 Insert eccentric key into hole and turn until cassette is in desired

position.

1

1000

5 Keep eccentric key permanently in contact with the cassette

so that it remains in position. Tighten clamping wedge (torque

moment 12 Nm).

Milling / Cassette milling cutters