Page 323 - Tungaloy Catalog

P. 323

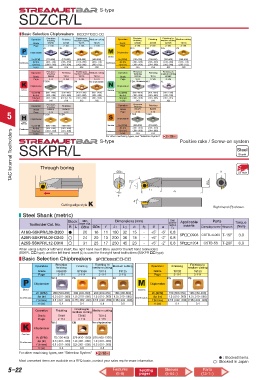

S-type

SDZCR/L

Basic Selection Chipbreakers DCoo11T3oo-oo

Precision Finishing to Precision Finishing to

Operation finishing Finishing medium cutting Medium cutting Operation finishing Finishing medium cutting Medium cutting

Grade SH730 AH725 T9115 T9125 Grade GH330 AH725 AH725 T9115

Page 2-108 2-105 2-106 2-109 Page 2-105 2-105 2-106 2-109

JS PSF PS PM W15 PSF PSS PM

Chipbreaker Chipbreaker

Steel Stainless

Vc (SFM) (170-600) (170-600) (400-800) (400-800) Vc (SFM) (100-150) (150-600) (150-600) (250-400)

ap (in) (.001-.120) (.005-.030) (.010-.060) (.040-.118) ap (in) (.001-.080) (.005-.030) (.010-.060) (.040-.118)

Continuous Continuous

f (in/rev) (.0001-.003) (.001-.006) (.002-.008) (.003-.012) f (in/rev) (.001-.006) (.001-.006) (.002-.008) (.003-.012)

rε (in) .008 .016 .032 .032 rε (in) .016 .016 .032 .032

Precision Finishing to Precision Finishing to

Operation finishing Finishing medium cutting Medium cutting Operation finishing Finishing medium cutting

Grade BX930 TH10 T5115 T5115 Grade DX120 TH10 KF05F

Page 3-14 2-105 2-106 2-110 Page 3-24 2-105 2-106

T-CBN W15 CM No chipbreaker T-DIA With chipbreaker W15 AL

Chipbreaker Chipbreaker

Cast lron Non-ferrous

Vc (SFM) (600-1400) (100-400) (450-1300) (450-1300) Vc (SFM) (800-4000) (300-3000) (200-1500)

ap (in) (.001-.006) (.001-.080) (.001-.080) (.001-.080) ap (in) (.001-.006) (.001-.080) (.020-.180)

Continuous Continuous

f (in/rev) (.001-.008) (0.0.3-0.15) (.001-.008) (.001-.008) f (in/rev) (.001-.008) (.001-.006) (.007-.015)

rε (in) .016 .016 .032 .032 rε (in) .016 .016 .032

Operation Precision Finishing Operation Precision Finishing

finishing

finishing

Grade BXM10 BXM20 Grade BX470 BX950

Page

3-14

5 Chipbreaker T-CBN T-CBN Chipbreaker T-CBN T-CBN

3-12

3-12

Page

3-12

Hard

Materials

Superalloys

(300-800)

(230-900)

Vc (SFM)

(500-1100)

Vc (SFM) (.0001-.003) (.001-.006) For other machining types, see “Selection System” 2-18~

(400-750)

(.005-.030)

(.001-.006)

ap (in)

ap (in)

(.001-.006)

Continuous

TAC Internal Toolholders SSKPR/L S-type Positive rake / Screw-on system

f (in/rev)

(.001-.008)

(.001-.008)

(.001-.006)

f (in/rev)

Continuous

.016

rε (in)

.016

.016

.016

rε (in)

Steel

Shank

Through boring

ØDm

75°

f ØDs h Oil Hole

L2

L1

α

Cutting edge style K θ

Right hand (R) shown.

Steel Shank (metric)

Std.

Stock Min Dimensions (mm) corner Applicable Parts Torque

Toolholder Cat. No. bore.dia. radius

R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench (N·m)

A16Q-SSKPR/L09-D200 d 20 16 11 180 32 15 - +5˚ -6˚ 0.8 SPoo0903 CSTB-4L060 T-15F 3.0

A20R-SSKPR/L09-D240 24 20 13 200 36 18 - +5˚ -2˚ 0.8

A25S-SSKPR/L12-D310 31 25 17 250 45 23 - +5˚ -2˚ 0.8 SPoo1204 CSTB-5S T-20F 6.0

When using a right or left hand insert, the right hand insert (R) is used for the left hand toolholders

(SSKPL oo type), and the left hand insert (L) is used for the right hand toolholders (SSKPR oo type).

Basic Selection Chipbreakers SPoo0903oo-oo

Precision Finishing to Finishing to

Operation Finishing Medium cutting Operation Finishing

finishing medium cutting medium cutting

Grade NS9530 GT9530 T9115 T9125 Grade T6120 T6130

Page 2-114 2-114 2-114 2-115 Page 2-114 2-114

W15 PS PS 24 PS PS

Chipbreaker Chipbreaker

Steel Stainless

Vc (SFM) 200 (500-800) 200 (400-850) 220 (400-850) 180 (400-800) Vc (SFM) 150 (300-550) 120 (250-400)

ap (in) 0.5 (.001-.080) 1.5 (.010-.060) 1.5 (.010-.060) 1.5 (.015-.080) ap (in) 1.5 (.010-.060) 1.5 (.010-.060)

Continuous Continuous

f (in/rev) 0.1 (.001-.006) 0.15 (.002-.008) 0.15 (.002-.008) 0.15 (.002-.008) f (in/rev) 0.15 (.002-.008) 0.15 (.002-.008)

rε (in) 0.4 0.4 0.8 0.8 rε (in) 0.4 0.4

Finishing to

Operation Finishing medium cutting Medium cutting

Grade TH10 T5115 T5115

Page 2-114 2-114 2-115

W15 CM No chipbreaker

Chipbreaker

Cast lron

Vc (SFM) 70 (100-400) 270 (450-1300) 270 (450-1300)

ap (in) 0.5 (.001-.080) 1.0 (.001-.080) 1.0 (.001-.080)

Continuous

f (in/rev) 0.1 (.001-.006) 0.2 (.001-.008) 0.2 (.001-.008)

rε (in) 0.4 0.8 0.8

For other machining types, see “Selection System” 2-18~

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. : Stocked in Japan

5–22 Features Relating Sleeves Parts

(5-6) pages (5-64~) (13-1~)