Page 390 - Tungaloy Catalog

P. 390

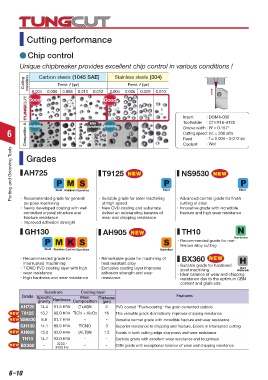

Cutting performance

Chip control

Unique chipbreaker provides excellent chip control in various conditions !

Cutting condition Carbon steels (1045 SAE) Stainless steels (304)

Feed: f (ipr)

Feed: f (ipr)

0.004 0.006 0.008 0.010 0.012 0.004 0.006 0.008 0.010

Good Good

Insert : DGM4-030

Toolholder : CTER16-4T25

With

Competitor A Feed : f = 0.004 - 0.012 ipr

6 Unstable vibration Unstable Groove width : W = 0.157"

Cutting speed: Vc = 330 sfm

: Wet

Coolant

Parting and Grooving Tools AH725 T9125 NEW NS9530 NEW

Grades

Steel

Steel

Steel Stainless Superalloys

・ Recommended grade for general

purpose machining ・ Suitable grade for steel machining ・ Advanced cermet grade for finish

cutting of steel

at high speed

・ Newly developed coating with well ・ New CVD coating and substrate ・ Innovative grade with incredible

controlled crystal structure and deliver an outstanding balance of fracture and high wear resistance

fracture resistance wear and chipping resistance

・ Improved adhesion strength

GH130 AH905 NEW TH10

Non-ferrous

・ Recommended grade for non-

ferrous alloy cutting

Steel Stainless Cast Iron Superalloys Superalloys

・ Recommended grade for ・ Remarkable grade for machining of BX360 NEW

interrupted machining heat resistant alloy ・ Suitable grade for hardened

・ TiCNO PVD coating layer with high ・ Exclusive coating layer improves steel machining Materials

Hard

wear resistance adhesion strength and wear ・ Ideal balance of wear and chipping

・ High hardness and wear resistance resistance resistance due to the optimum CBN

content and grain size

Substrate Coating layer

Grade Specific Main Thickness Features

gravity Hardness Composition (μm)

AH725 14.4 91.5 HRA (Ti,AI)N 2 PVD coated "Flash-coating" fine grain cemented carbide

NEW T9125 13.7 90.0 HRA TiCN + Al2O3 16 This versatile grade dramatically improves chipping resistance

NEW NS9530 6.8 91.7 HRA - - Versatile cermet grade with incredible fracture and wear resistance

GH130 14.1 89.5 HRA TiCNO 3 Superior resistance to chipping and fracture. Excels in interrupted cutting

NEW AH905 15.0 93.0 HRA (AI,Ti)N 1.5 Excels in both cutting edge sharpness and wear resistance

TH10 14.7 92.0 HRA - - Carbide grade with excellent wear resistance and toughness

3200 -

NEW BX360 - 3400 Hv - - CBN grade with exceptional balance of wear and chipping resistance

6–10