Page 429 - Tungaloy Catalog

P. 429

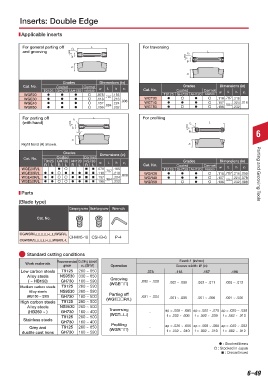

Inserts: Double Edge

Applicable inserts

For general parting off L For traversing

and grooving +.004 r Џ w 0 +.004 r Џ L

w 0

Grades Dimensions (in)

Cat. No. Coated Cermet Grades Dimensions (in)

T9125 GH730 AH120 NS9530 w L h rε Cat. No. Coated Cermet w L h rε

WGE20 .078 .185 T9125 GH730 AH120 NS9530

WGE30 .118 .787 .216 .008 WGT30 .118 .787 .216

WGE40 .157 .224 WGT40 .157 .984 .224 .016

WGE50 .196 .984 .232 WGT50 .196 .232

For parting off r ε L For profiling

(with hand) +.004 w 0 r ε L

w +.004 0

8˚ 6

Right hand (R) shown.

Grades Dimensions (in)

Cat. No. Coated Cermet

T9125 GH730 AH120 NS730 w L h rε Grades Dimensions (in)

R L R L R L R L Cat. No. Coated Cermet

WGE20R/L .078 .185 T9125 GH730 AH120 NS9530 w L h rε

WGE30R/L .118 .787 .216 .008 WGR30 .118 .787 .216 .059 Parting and Grooving Tools

WGE40R/L .157 .224 WGR40 .157 .224 .078

WGE50R/L .196 .984 .232 WGR50 .196 .984 .232 .098

Parts

(Blade type)

Clamping screw Blade fixing screw Wrench

Cat. No.

Note: Apply to GR/GL cartridges.

CGWSR/Lhhhh-hhWGR/L

CHHM5-18 CSHB-6 P-4

CGWSR/Lhhhh-hhWGR/L-L

Standard cutting conditions

Recommended Cutting speed Feed: f (in/rev)

Work materials

grade vc (SFM) Operation Groove width: W (in)

Low carbon steels T9125 260 ~ 650 .078 .118 .157 .196

Alloy steels NS9530 330 ~ 650

Grooving

( ~ HB150) GH730 160 ~ 590 (WGEhh) .002 ~ .008 .002 ~ .009 .003 ~ .011 .003 ~ .012

Medium carbon steels T9125 260 ~ 590

Alloy steels NS9530 260 ~ 590 Parting off

(HB150 ~ 250) GH730 160 ~ 500 (WGEhhR/L) .001 ~ .004 .001 ~ .006 .001 ~ .006 .001 ~ .006

High carbon steels T9125 260 ~ 500

Alloy steels NS9530 260 ~ 500

(HB250 ~ ) GH730 160 ~ 400 Traversing - ap = .008 ~ .060 ap = .020 ~ .078 ap = .020 ~ .098

T9125 260 ~ 500 (WGThh) f = .002 ~ .006 f = .002 ~ .009 f = .002 ~ .010

Stainless steels

GH730 160 ~ 400

Profiling

Grey and T9125 260 ~ 650 (WGRhh) - ap = .020 ~ .055 ap = .008 ~ .060 ap = .020 ~ .062

ductile cast irons GH730 160 ~ 590 f = .002 ~ .010 f = .002 ~ .010 f = .002 ~ .012

: Stocked items

: Stocked in Japan

: Discontinued

6–49