Page 431 - Tungaloy Catalog

P. 431

CGSS

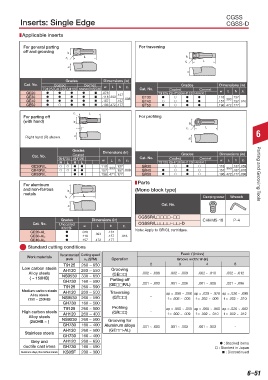

Inserts: Single Edge CGSS-D

Applicable inserts

For general parting For traversing

off and grooving w

w

r ε

r ε

Grades Dimensions (in)

Cat. No. Coated Cermet Grades Dimensions (in)

T9125 GH730 AH120 NS9530 NS530 w L h rε Cat. No. Coated Cermet

GE20 .078 T9125 GH730 AH120 NS9530 w L h rε

GE30 .118 .393 .137 .008 GT30 s .118 .137

GE40 .157 .157 GT40 s s .157 .393 .157 .016

GE50 s .196 .472 .177 GT50 s .196 .472 .177

r ε L

For parting off For profiling

(with hand) w w

r ε

8˚ 6

Right hand (R) shown. h

Grades Dimensions (in)

Cat. No. Coated Grades Dimensions (in)

GH730 AH120 w L h rε Cat. No. Coated Cermet w L h rε

R L R L T9125 GH730 AH120 NS9530

GE30R/L s s .118 .393 .137 GR30 s s .118 .393 .137 .059

GE40R/L s s .157 .157 .008 GR40 s s .157 .157 .078

GE50R/L .196 .471 .177 GR50 s s .196 .472 .177 .098 Parting and Grooving Tools

Parts

For aluminum

and non-ferrous w (Mono block type)

metals

r ε Clamping screw Wrench

Cat. No.

CGSSR/Lhhhh-hh

Grades Dimensions (in) CHHM5-18 P-4

Cat. No. Uncoated CGSSR/Lhhhh-hh-D

KS05F w L h rε Note: Apply to GR/GL cartridges.

GE20-AL .078 .137

GE30-AL .118 .393 .157 .016

GE40-AL .157 .472 .177

Standard cutting conditions

Feed: f (in/rev)

Work materials Recommended Cutting speed Operation Groove width: W (in)

grade

vc (SFM)

T9125 260 ~ 650 2 3 4 5

Low carbon steels AH120 260 ~ 550 Grooving

Alloy steels NS9530 (GEhh) .002 ~ .008 .002 ~ .009 .002 ~ .010 .002 ~ .012

( ~ 150HB) 330 ~ 650 Parting off

GH730 160 ~ 590 .001 ~ .003 .001 ~ .006 .001 ~ .006 .001 ~ .006

T9125 260 ~ 590 (GEhhR/L)

Medium carbon steels AH120 260 ~ 500 Traversing

Alloy steels (GThh) - ap = .008 ~ .060 ap = .020 ~ .078 ap = .020 ~ .098

(150 ~ 250HB) NS9530 260 ~ 590 f = .002 ~ .006 f = .002 ~ .009 f = .002 ~ .010

GH730 160 ~ 500

T9125 260 ~ 500 Profiling ap = .050 ~ .055 ap = .008 ~ .060 ap = .020 ~ .062

High carbon steels AH120 260 ~ 400 (GRhh) - f = .002 ~ .009 f = .002 ~ .010 f = .002 ~ .012

Alloy steels

(250HB ~ ) NS9530 260 ~ 500 Grooving for

GH730 160 ~ 400 Aluminum alloys .001 ~ .003 .001 ~ .003 .001 ~ .003 -

AH120 260 ~ 500 (GEhh-AL)

Stainless steels

GH730 160 ~ 400

Grey and AH120 260 ~ 650 : Stocked items

ductile cast irons GH730 160 ~ 590 : Stocked in Japan

Aluminum alloys, Non-ferrous metals KS05F 200 ~ 300 : Discontinued

6–51