Page 567 - Tungaloy Catalog

P. 567

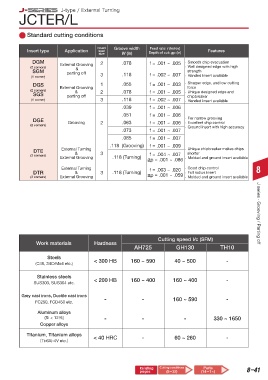

J-type / External Turning

JCTER/L

Standard cutting conditions

Insert Groove width Feed rate: f (in/rev)

Insert type Application seat Features

size W (in) Depth of cut: ap (in)

DGM External Grooving 2 .078 f = .001 ~ .005 • Smooth chip evacuation

(2 corners) & • Well designed edge with high

SGM parting off strength

(1 corner) 3 .118 f = .002 ~ .007 • Handed insert available

DGS External Grooving 1 .055 f = .001 ~ .003 • Sharper edge, and low cutting

force

(2 corners) & 2 .078 f = .001 ~ .005 • Unique designed edge and

SGS parting off chipbreaker

(1 corner) 3 .118 f = .002 ~ .007 • Handed insert available

.039 f = .001 ~ .006

.051 f = .001 ~ .006

DGE Grooving 2 .063 f = .001 ~ .006 • For narrow grooving

• Excellent chip control

(2 corners) • Ground insert with high accuracy

.073 f = .001 ~ .007

.085 f = .001 ~ .007

.118 (Grooving) f = .001 ~ .009

DTE External Turning 3 • Unique chipbreaker makes chips

&

shorter

(2 corners) f = .004 ~ .007

External Grooving .118 (Turning) • Molded and ground insert available

ap = .001 ~ .086

External Turning f = .003 ~ .020 • Good chip control 8

DTR & 3 .118 (Turning) • Full radius insert

(2 corners) External Grooving ap = .001 ~ .059 • Molded and ground insert available

Cutting speed Vc (SFM) J series · Grooving / Parting off

Work materials Hardness

AH725 GH130 TH10

Steels

(C45, 34CrMo4 etc.) < 300 HB 160 ~ 590 40 ~ 500 -

Stainless steels

SUS303, SUS304 etc. < 200 HB 160 ~ 400 160 ~ 400 -

Grey cast irons, Ductile cast irons

FC250, FCD450 etc. - - 160 ~ 590 -

Aluminum alloys

(Si < 12%) - - - 330 ~ 1650

Copper alloys

Titanium, Titanium alloys < 40 HRC - 60 ~ 260 -

(Ti-6Al-4V etc.)

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Cutting conditions Parts

pages (8-32) (14-1~) 8–41