Page 571 - Tungaloy Catalog

P. 571

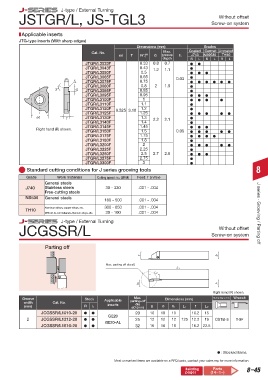

J-type / External Turning

JSTGR/L, JS-TGL3 Screw-on system

Without offset

Applicable inserts

JTG-type inserts (With sharp edges)

Dimensions (mm) Grades

Cat. No. Max. Coated Cermet Uncoated

ød T W +0.05 G groove rε J740 NS9530 TH10

0

depth R L R L R L

JTGR/L3033F 0.33 0.8 0.7

JTGR/L3043F 0.43 1.2 1.1

JTGR/L3050F 0.5

JTGR/L3065F 0.65

W 0.03

r ε JTGR/L3075F 0.75

JTGR/L3080F 0.8 2 1.9

2° G JTGR/L3085F 0.85

JTGR/L3095F 0.95

JTGR/L3100F 1

JTGR/L3110F 1.1

JTGR/L3120F 9.525 3.18 1.2

JTGR/L3125F 1.25

ød T JTGR/L3130F 1.3 2.2 2.1

JTGR/L3140F 1.4

JTGR/L3145F 1.45

Right hand (R) shown.

JTGR/L3150F 1.5 0.05

JTGR/L3175F 1.75

JTGR/L3180F 1.8

JTGR/L3200F 2

JTGR/L3225F 2.25

JTGR/L3250F 2.5 2.7 2.6

JTGR/L3275F 2.75

JTGR/L3300F 3

Standard cutting conditions for J series grooving tools 8

Grade Work materials Cutting speed: vc (SFM) Feed: f (in/rev)

General steels

J740 Stainless steels 30 - 330 .001 - .004

Free-cutting steels

NS530 General steels 160 - 500 .001 - .004

TH10 Aluminum alloys, copper alloys, etc. 300 - 650 .001 - .004

Difficult-to-cut materials, titanium alloys, etc. 30 - 100 .001 - .004 J series · Grooving / Parting off

J-type / External Turning

JCGSSR/L Screw-on system

Without offset

Parting off

f b

Max. parting off dia øD

L1

L2

h1 h

Right hand (R) shown.

Groove Stock Applicable Max. Dimensions (mm) Clamping screw Wrench

width Cat. No. parting-off

dia

(mm) R L inserts øD (mm) b h h1 L1 f L2

JCGSSR/L1010-20 20 10 10 10 10.2 15

2 JCGSSR/L1212-20 GE20 25 12 12 12 125 12.2 19 CSTB-3 T-9F

GE20-AL

JCGSSR/L1616-20 32 16 16 16 16.2 22.5

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Cutting conditions Relating Parts Parts

pages (8-32) pages (14-1~) 8–45

(14-1~)