Page 1404 - All Industrial Tool Supply | General Catalog

P. 1404

‘H’ Head Style & Technical Information • DRILL JIG BUSHINGS

1401

H Style Precision Drill Jig Bushings (Cont.) Quantity BreakS:

A.S.A. Standard • Outside Diameter Is Ground For Quantity Discount,

Please See Page 1400

Features: ♦ Tolerances Shown On Previous Page.

• The bushing head prevents you from pushing the

bushing all the way through the workpiece. ♦ Specify ID x OD x Length When Ordering.

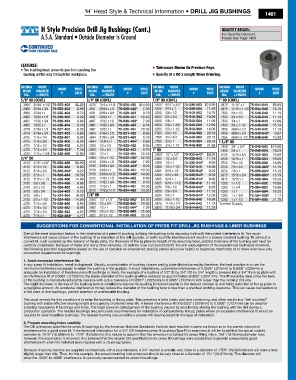

DeCimal inSiDe OrDer PriCe DeCimal inSiDe OrDer PriCe DeCimal inSiDe OrDer PriCe DeCimal inSiDe OrDer PriCe

inSiDe Diameter # eaCH inSiDe Diameter # eaCH inSiDe Diameter # eaCH inSiDe Diameter # eaCH

Dia. x lengtH Dia. x lengtH Dia. x lengtH Dia. x lengtH

5/8" OD (COnt.) 3/4" OD (COnt.) 7/8" OD (COnt.) 1" OD (COnt.)

.3906" 25/64" x 1/2" 75-525-402 $8.29 .4375" 7/16 x 1-1/2 75-528-480 $14.99 .5625" 9/16" x 3/4" 75-536-563 $10.99 .6875" 11/16" x 1" 75-544-644 $9.99

.3906 25/64 x 3/4 75-525-403 8.99 .4531 29/64 x 1/2 75-529-482* 7.39 .5625 9/16 x 1 75-536-564 11.59 .6875 11/16 x 1-1/2 75-544-640 15.19

.3906 25/64 x 1 75-525-404 9.79 .4531 29/64 x 3/4 75-529-483 9.79 .6250 5/8 x 1/2 75-540-562 10.79 .7500 3/4 x 1/2 75-548-642 11.19

.4062 13/32 x 1/2 75-526-402 8.29 .4531 29/64 x 1 75-529-484 10.49 .6250 5/8 x 3/4 75-540-563 10.99 .7500 3/4 x 3/4 75-548-643 11.19

.4062 13/32 x 3/4 75-526-403 8.99 .4687 15/32 x 1/2 75-530-482* 7.39 .6250 5/8 x 1 75-540-564 11.59 .7500 3/4 x 1 75-548-644 12.09

.4062 13/32 x 1 75-526-404 9.79 .4687 15/32 x 3/4 75-530-483 9.79 .6250 5/8 x 1-3/8 75-540-568 12.69 .7500 3/4 x 1-1/2 75-548-640 15.19

.4219 27/64 x 1/2 75-527-402 8.29 .4687 15/32 x 1 75-530-484 10.39 .6250 5/8 x 1-1/2 75-540-560 14.09 .7656 49/64 x 1/2 75-549-642 11.19

.4219 27/64 x 3/4 75-527-403 8.99 .4844 31/64 x 1/2 75-531-482 8.99 .7500 3/4 x 1/2 75-548-562 20.19 .7656 49/64 x 3/4 75-549-643* 9.97

.4375 7/16 x 1/4 75-528-401 8.99 .4844 31/64 x 3/4 75-531-483 9.79 .7500 3/4 x 3/4 75-548-563 20.19 .7656 49/64 x1-1/2 75-549-640 16.99

.4375 7/16 x 3/8 75-528-406 8.29 .4844 31/64 x 1 75-531-484* 8.69 .7500 3/4 x 1 75-548-564 20.19 1-3/8" OD

.4375 7/16 x 1/2 75-528-402 8.29 .5000 1/2 x 1/2 75-532-482 8.99 .7500 3/4 x 1-1/2 75-548-560 31.89 .7500" 3/4" x 3/4" 75-548-883 $16.69

.4375 7/16 x 3/4 75-528-403* 7.39 .5000 1/2 x 3/4 75-532-483 9.79 1" OD .7500 3/4 x 1 75-548-884 18.29

.4375 7/16 x 1-3/8 75-528-408 12.99 .5000 1/2 x 1 75-532-484 10.49 .5000" 1/2" x 1/2" 75-532-642* $9.29 .8125 13/16 x 3/4 75-552-883 16.69

3/4" OD .5000 1/2 x 1-1/2 75-532-480* 12.39 .5000 1/2 x 3/4 75-532-643 11.19 .8125 13/16 x 1 75-552-884 18.29

.3125" 5/16" x 3/8" 75-520-486 $8.99 .5156 33/64 x 1/2 75-533-482* 7.89 .5000 1/2 x 1 75-532-644* 9.99 .8750 7/8 x 1/2 75-556-882 18.09

.3125 5/16 x 1/2 75-520-482 8.99 .5156 33/64 x 3/4 75-533-483* 9.29 .5000 1/2 x 1-1/2 75-532-640 16.99 .8750 7/8 x 3/4 75-556-883* 13.79

.3125 5/16 x 3/4 75-520-483* 9.29 .5156 33/64 x 1 75-533-484 10.39 .5625 9/16 x 1/2 75-536-642* 9.29 .8750 7/8 x 1 75-556-884* 15.19

.3125 5/16 x 1 75-520-484 10.39 .5156 33/64x1-1/2 75-533-480* 14.99 .5625 9/16 x 3/4 75-536-643* 9.29 .9375 15/16 x 3/4 75-560-883* 13.79

.3125 5/16 x 1-1/2 75-520-480 14.99 .5312 17/32 x 1/2 75-534-482 8.99 .5625 9/16 x 1 75-536-644* 9.99 .9375 15/16 x 1 75-560-884 18.29

.3750 3/8 x 3/8 75-524-486 8.99 .5312 17/32 x 3/4 75-534-483 9.79 .5625 9/16 x 1-1/2 75-536-640 11.19 1.000 1 x 1/2 75-564-882 18.09

.3750 3/8 x 1/2 75-524-482 8.99 .5312 17/32 x 1 75-534-484 10.39 .6250 5/8 x 1/2 75-540-642* 9.29 1.000 1 x 3/4 75-564-883 16.69

.3750 3/8 x 3/4 75-524-483 9.79 .5312 17/32x1-1/2 75-534-480 13.59 .6250 5/8 x 3/4 75-540-643 11.19 1.000 1 x 1 75-564-884 18.29

.3750 3/8 x 1 75-524-484 10.39 7/8" OD .6250 5/8 x 1 75-540-644* 12.09 1.000 1 x 1-3/8 75-564-888* 7.17

.3750 3/8 x 1-1/2 75-524-480 14.99 .5000" 1/2" x 1/2" 75-532-562* $6.99 .6250 5/8 x 1-1/2 75-540-640 16.99 1.000 1 x 1-1/2 75-564-880 21.79

.4375 7/16 x 3/8 75-528-486 8.99 .5000 1/2 x 3/4 75-532-563 10.89 .6875 11/16 x 1/2 75-544-642 11.19 *Limited Supply.

.4375 7/16 x 1/2 75-528-482 8.99 .5000 1/2 x 1 75-532-564* 7.99 .6875 11/16 x 3/4 75-544-643 11.19

.4375 7/16 x 3/4 75-528-483 8.59 .5000 1/2 x 1-1/2 75-532-560 15.59

.4375 7/16 x 1 75-528-484* 4.17 .5625 9/16 x 1/2 75-536-562 10.79

SUGGeStIoNS FoR CoNveNtIoNaL INStaLLatIoN oF PReSS FIt DRILL JIG BUSHINGS & LINeR BUSHINGS

One of the more important factors in the installation of a press fit bushing is fitting the bushing to its mounting hole with the correct interference fit. Too much

interference will cause closure of the bushing ID or distortion of the drill jig plate, or both; too little interference will result in a loosely installed bushing. To arrive at a

correct fit, such variables as the material of the jig plate, the thickness of the jig plate (or length of the mounting hole), and the thickness of the bushing wall must be

carefully considered. Because of these and many other variables, no definite rules can substitute for the skill and judgment of the experienced toolmaker. However,

the following practical suggestions (based on the use of cast-iron or unhardened steel jig plates) will prove helpful to beginning machinists or to those who have only

occasional requirements for bushings.

1. avoid excessive interference fits

In any press fit installation, metal is displaced. Usually, a combination of bushing closure and jig plate distortion results; therefore, the best practice is to use the

minimum interference necessary to retain the bushing in the jig plate. In most installations, a diametral interference of 0.0005" (.013mm) to 0.0008" (.020mm) is

adequate for installation of headless press fit bushings or liners. For example, if a bushing of 1/2" ID by 3/4" OD by 3/4" length is pressed into a 3/4" thick jig plate with

an interference fit of 0.0006" (.0152mm), the inside diameter of the bushing will be reduced by approximately 0.0002" (.0051mm). This fit would be ideal since the bore

of the bushing is manufactured slightly oversize with a plus tolerance of 0.0001" (.0025mm) to 0.0005" (.0127mm) inch larger than the nominal drill size.

The slight decrease in the size of the bushing bore at installation reduces the bushing ID almost exactly to the desired nominal ID and holds distortion of the jig plate to

a negligible amount. An excessive interference fit may reduce the diameter of the bushing bore to less than a practical working clearance. This can cause tool seizure or,

in the case of liner bushings, prevent insertion of a renewable bushing.

The usual remedy for this condition is to relap the bushing in the jig plate. This operation is both costly and time consuming, and often results in a “bell mouthed”

bushing with a less effective bearing length and a greatly shortened wear life. A lesser interference fit of 0.0003" (.0076mm) to 0.0005" (.0127mm) can be used for

installing head press fit bushings and liners. The head prevents dislodgement of the bushing caused by accidentally striking the bushing with the drill during a

production operation. The headed bushings are particularly recommended for installation in comparatively thin jig plates where an excessive interference fit would be

required to retain headless bushings. The headed bushing also provides a greater drill bearing length in this type of installation.

2. Prepare mounting holes carefully

The OD tolerances specified for press fit bushings by the American National Standards Institute have resulted in some confusion as to the correct amount of

interference for a good press fit. If the technical information for a 3/4" OD headless press fit bushing (Type P) is examined, it will be found that the actual outside

diameter is .7515" (19.088mm) to .7518" (19.096mm). It is natural to assume that this dimension is correct for press fitting into a .750" (19.05mm) diameter hole;

however, this assumption is incorrect. It is believed that the original OD specifications for press fit bushings were established to provide a reasonably good

interference fit when the hole had been reamed with a chucking reamer.

Because chucking reamers are supplied commercially with a plus tolerance, a 3/4" reamer is actually very close to a diameter of .7505" (19.063mm) and will ream a hole

slightly larger than this. Thus, for this example, the actual mounting hole produced should be very close to a diameter of .751" (19.075mm). This diameter will

allow the .0005" to .0008" interference fit previously recommended for press fit bushings.