Page 473 - All Industrial Tool Supply | General Catalog

P. 473

Milling - Face Mills & Inserts • ISCAR

471

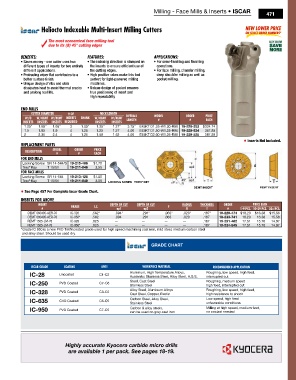

Heliocto Indexable Multi-Insert Milling Cutters

The most economical face milling tool

due to its (8) 45° cutting edges

Benefits: feAtures: APPLiCAtiOns:

• Saves money - one cutter uses two • The indexing direction is stamped on • For semi-finishing and finishing

different types of inserts for two entirely the inserts to ensure efficient use of operations.

different applications. the cutting edges. • For face milling, chamfer milling,

• Protruding wiper flat contributes to a • High positive rakes make this tool deep shoulder milling as well as

better surface finish. perfect for light-powered milling pocket milling.

• Unique design of ribs and slots machines.

dissipates heat to avoid thermal cracks • Unique design of pocket ensures

and prolong tool life. true positioning of insert and

high repeatablity

enD MIlls

_____CutteR DIaMeteR_____ # oF ____neCk lengtH____ oveRall MoDel oRDeR pRICe

W/o W/oeMt W/ReMt InseRts sHank W/oeMt W/ReMt lengtH # # eaCH

InseRts InseRts InseRts RequIReD InseRts InseRts

1.25" 1.60" 1.65" 3 1.00" 1.25" 1.27" 3.75" E45KT D1.25-W1.00-R06 19-229-533 $324.74

1.5 1.85 1.9 4 1.25 1.25 1.27 4.00 E45KT D1.50-W1.25-R06 19-229-534 367.89

2 2.35 2.4 4 1.25 1.50 1.52 4.00 E45KT D2.00-W1.25-R06 19-229-535 387.28

♦ Inserts Not Included.

ReplaCeMent paRts

DesCRIptIon MoDel oRDeR pRICe

eaCH

#

#

FoR enD MIlls

Locking Screw SR 14-544/S 19-215-466 $1.70

Torx Key T 15/51 19-211-849 3.55

®

FoR FaCe MIlls

Locking Screw SR 14-544 19-213-128 $1.80

Torx Key T 15/51 19-211-849 3.55 LOCKING SCREW TORX ® KEY

®

OEMT INSERT REMT INSERT

♦ See Page 457 For Complete Iscar Grade Chart.

InseRts FoR above

InseRt gRaDe I.C. DeptH oF Cut DeptH oF Cut F RaDIus tHICkness oRDeR _______pRICe eaCH_______

# ap1 ap2 R t # 1-9 pCs. 10-29 pCs. 30+ pCs.

OEMT 060405-AER-76 IC-328 .562" .094" .291" .063" .020" .187" 19-229-474 $18.20 $16.38 $15.56

OEMT 060405-AER-76 IC-950* .562 .094 .291 .063 .020 .187 19-233-741 18.20 16.38 15.56

REMT 1505-LM-76 IC-328 .625 — — — — .187 19-231-482 17.51 15.76 14.97

REMT 1505-LM-76 IC-950* .625 — — — — .187 19-234-949 17.51 15.76 14.97

*Grade IC 950 is a new PVD TiAlN coated grade used for high speed machining cast iron, mild steel, medium carbon steel

and alloy steel. Should be used dry.

GRAdE ChART

ISCAR GRADE COATING ANSI WORKPIECE MATERIAL RECOMMENDED APPLICATION

IC-28 Uncoated C1-C2 Aluminum, High Temperature Alloys, Roughing, low speed, high feed,

Austenitic Stainless Steel, Alloy Steel, H.S.S.

interrupted cut

IC-250 PVD Coated C7-C6 Steel, Cast Steel Roughing, medium speed

high feed, interrupted cut

Stainless Steel

IC-328 PVD Coated C3-C2 Alloy Steel, Aluminum Alloys Roughing, low speed, high feed,

high resistance to shock

Cast Steel, Copper, Exotic

IC-635 CVD Coated C6-C5 Carbon Steel, Alloy Steel, Low speed, high feed

unfavorable conditions

Stainless Steel

IC-950 PVD Coated C7-C5 Carbon & alloy steels, Milling at high speed, medium feed,

no coolant needed

can be used on grey cast iron

Highly accurate Kyocera carbide micro drills

are available 1 per pack. See pages 18-19.