Page 475 - All Industrial Tool Supply | General Catalog

P. 475

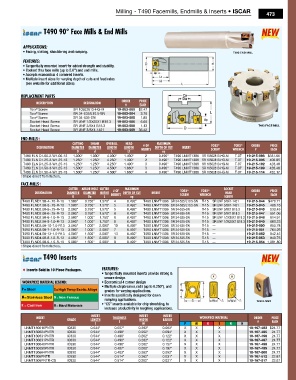

Milling - T490 Facemills, Endmills & Inserts • ISCAR

473

T490 90° Face Mills & End Mills

APPLICATIONS:

• Facing, slotting, shouldering and ramping. T490 END MILL

FeATureS:

• Tangentially mounted insert for added strength and stability.

• Coolant thru face mills (up to 5.0") and end mills.

• Accepts economical 4 cornered inserts.

• Multiple insert sizes for varying depth of cuts and feed rates

(see website for additional sizes).

REplacEMEnT paRTs

oRDER pRicE

DEscRipTion DEsignaTion

# Each

Torx Screw SR 10502813-HG-M 19-003-000 $2.47

®

Torx Screw SR 34-535/L10.5-SN 19-003-004 3.76

®

Torx Screw SR 34-535-SN 19-003-005 1.85

®

Socket Head Screw SR UNF 1/2X20X1 B18.3 19-003-006 6.65

Socket Head Screw SR UNF 3/8X1 B18.3 19-003-008 1.13 T490 FACE MILL

Socket Head Screw SR UNF 3/8X1-1421 19-003-009 36.42

EnD Mills†

cuTTing shank ovERall hEaD MaxiMuM ® ®

ToRx

ToRx

# oF

DEsignaTion DiaMETER DiaMETER lEngTh lEngTh insERTs DEpTh oF cuT insERT scREw wREnch oRDER pRicE

#

Each

D d l l1 ap

T490 ELN D1.00-2-W1.00-13 1.000" 1.000" 4.000" 1.400" 2 0.490" T490 LNMT1306 SR 10502813-HG-M T-07 19-215-086 $331.66

T490 ELN D1.25-2-W1.25-13 1.250" 1.250" 4.250" 1.400" 2 0.490" T490 LNMT1306 SR 10502813-HG-M T-07 19-215-095 406.85

T490 ELN D1.25-3-W1.25-13 1.250" 1.250" 4.250" 1.400" 3 0.490" T490 LNMT1306 SR 10502813-HG-M T-07 19-215-102 428.48

T490 ELN D1.50-3-W1.25-13 1.500" 1.250" 4.500" 1.660" 3 0.490" T490 LNMT1306 SR 10502813-HG-M T-07 19-215-109 428.48

T490 ELN D1.50-4-W1.25-13 1.500" 1.250" 4.500" 1.660" 4 0.490" T490 LNMT1306 SR 10502813-HG-M T-07 19-215-114 452.17

†Ships direct from factory.

FacE Mills†

cuTTER aRboR holE cuTTER MaxiMuM ® ® sockET

# oF

ToRx

ToRx

DEsignaTion DiaMETER DiaMETER hEighT insERTs DEpTh oF cuT insERT scREw wREnch hEaD oRDER pRicE

#

Each

D Da l ap scREw

T490 FLND1.50-4-.75-R-13 1.500" 0.750" 1.570" 4 0.492" T490 LNMT1306 SR 34-535/L10.5-SN T-15 SR UNF 3/8X1-1421 19-215-044 $470.71

T490 FLND1.50-5-.75-R-13 1.500" 0.750" 1.570" 5 0.492" T490 LNMT1306 SR 34-535/L10.5-SN T-15 SR UNF 3/8X1-1421 19-215-045 486.16

T490 FLND2.00-5-.75-R-13 2.000" 0.750" 1.570" 5 0.492" T490 LNMT1306 SR 34-535-SN T-15 SR UNF 3/8X1 B18.3 19-215-046 530.45

T490 FLND2.00-6-.75-R-13 2.000" 0.750" 1.570" 6 0.492" T490 LNMT1306 SR 34-535-SN T-15 SR UNF 3/8X1 B18.3 19-215-047 551.05

T490 FLND2.50-6-1.0-R-13 2.500" 1.000" 1.750" 6 0.492" T490 LNMT1306 SR 34-535-SN T-15 SR UNF 1/2X20X1 B18.3 19-215-048 614.91

T490 FLND2.50-8-1.0-R-13 2.500" 1.000" 1.750" 8 0.492" T490 LNMT1306 SR 34-535-SN T-15 SR UNF 1/2X20X1 B18.3 19-215-049 660.23

T490 FLND3.00-10-1.0-R13 3.000" 1.000" 2.000" 10 0.492" T490 LNMT1306 SR 34-535-SN T-15 — 19-215-050 850.78

T490 FLND3.00-7-1.0-R-13 3.000" 1.000" 2.000" 7 0.492" T490 LNMT1306 SR 34-535-SN T-15 — 19-215-051 764.26

T490 FLND4.00-13-1.5-R13 4.000" 1.500" 2.000" 13 0.492" T490 LNMT1306 SR 34-535-SN T-15 — 19-215-052 942.45

T490 FLND4.00-8-1.5-R-13 4.000" 1.500" 2.000" 8 0.492" T490 LNMT1306 SR 34-535-SN T-15 — 19-215-053 849.75

T490 FLND5.00-9-1.5-R-13 5.000" 1.500" 2.000" 9 0.492" T490 LNMT1306 SR 34-535-SN T-15 — 19-215-054 1,091.80

†Ships direct from factory.

T490 inserts

♦ Inserts Sold In 10 Piece Packages. FeATureS:

• Tangentially mounted inserts provide strong &

secure design.

• Economical 4 corner design

• Multiple chipbreaker, radii (up to 0.250"), and

grades for varying applications.

• Inserts specifically designed for down

ramping applications. T490 LNMT

• “CS” inserts available for chip shredding, to

increase productivity in roughing applications.

insERT insERT insERT

insERT gRaDE lEngTh ThicknEss wiDTh RaDius woRkpiEcE MaTERial oRDER pRicE

# s # Each

l w r p M k s n h

LNMT130616PNTR IC830 0.544" 0.507" 0.262" 0.063" X X X 19-167-493 $24.77

LNMT130624PNTR IC830 0.544" 0.498" 0.262" 0.094" X X X 19-167-495 24.77

LNMT130631PNTR IC330 0.544" 0.490" 0.262" 0.122" X X X 19-167-496 24.77

LNMT130631PNTR IC830 0.544" 0.490" 0.262" 0.122" X X X 19-167-497 24.77

LNMT130640PNTR IC830 0.544" 0.496" 0.262" 0.157" X X X 19-167-498 24.77

LNMT130650PNTR IC830 0.544" 0.487" 0.262" 0.197" X X X 19-167-499 24.77

LNMT130664PNTR IC830 0.544" 0.483" 0.262" 0.252" X X X 19-167-500 24.77

LNMT1306PNTR IC830 0.544" 0.514" 0.262" 0.031" X X X 19-167-512 22.87

LNMT1306PNTR-CS IC830 0.544" 0.514" 0.262" 0.031" X X X 19-167-517 22.87