Page 479 - All Industrial Tool Supply | General Catalog

P. 479

Technical Turning • KYOCERA

477

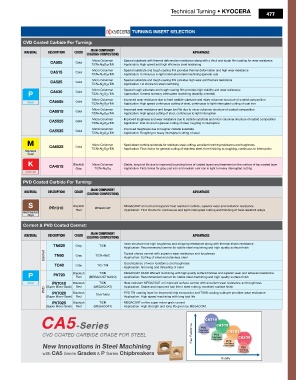

TuRning insERT sElECTiOn

CVD Coated Carbide For Turning:

Main coMponent

Material Description color aDvantages

(coating coMposition)

CA505 Gold Micro Columnar · Special substrate with thermal deformation resistance along with a thick and tough film coating for wear resistance

TiCN+Al 2 O 3 +TiN · Application: High speed and high efficiency steel machining

CA515 Gold Micro Columnar · Special substrate and tough coating film provides thermal deformation and high wear resistance

TiCN+Al 2 O 3 +TiN · Application: Continuous to light interrupted steel machining (general use)

Micro Columnar

CA525 Gold TiCN+Al 2 O 3 +TiN · Special substrate and tough coating film provides high wear and fracture resistance

· Application: 1st choice for steel machining

Micro Columnar

P CA530 Gold TiCN+Al 2 O 3 +TiN · Special tough substrate and tough coating film provides high stability and wear resistance

· Application: General to heavy interrupted machining (stability oriented)

Micro Columnar

Steel CA5505 Gold TiCN+Al 2 O 3 +TiN · Improved wear resistance due to hard carbide substrate and micro columnar structure of coated composition

· Application: High speed continuous cutting of steel, continuous to light interrupted cutting of cast iron

CA5515 Gold Micro Columnar · Improved wear resistance and longer tool life due to micro columnar structure of coated composition

TiCN+Al 2 O 3 +TiN · Application: High speed cutting of steel, continuous to light interruption

CA5525 Gold Micro Columnar · Improved toughness and wear resistance due to carbide substrate and micro columnar structure of coated composition

TiCN+Al 2 O 3 +TiN · Application: First choice for general cutting of steel, roughing to interruption

CA5535 Gold Micro Columnar · Improved toughness due to tougher carbide substrate

TiCN+Al 2 O 3 +TiN · Application: Roughing to heavy interrupted cutting of steel

M CA6525 Gold Micro Columnar · Specialized carbide substrate for stainless steel cutting, excellent notching resistance and toughness

Stainless TiCN+Al 2 O 3 +TiN · Application: First choice for general cutting of stainless steel, from finishing to roughing, continuous to interruption

Steel

K CA4515 Blackish Micro Columnar · Stable, long tool life due to improved bounding force of coated layers and treatment on the surface of top coated layer

Cast Iron Gray TiCN+Al 2 O 3 · Application: First choice for gray cast iron and nodular cast iron in light to heavy interrupted cutting

PVD Coated Carbide For Turning:

Main coMponent

Material Description color aDvantages

(coating coMposition)

s PR1310 Blackish MEGACOAT · MEGACOAT on hard and superior heat resistant carbide, superior wear and oxidation resistance

Heat-Resistant Red · Application: First choice for continuous and light interrupted cutting and finishing of heat-resistant alloys

Alloys

Cermet & PVD Coated Cermet:

Main coMponent

Material Description color aDvantages

(coating coMposition)

Tn620 Gray TiCN · Inner structure has high toughness and chipping resistance along with thermal shock resistance.

· Application: Recommended cermet for stable steel machining and high quality surface finish

Cermet Tn60 Gray TiCN+NbC · Typical choice cermet with superior wear resistance and toughness

· Application: Cutting of steel and stainless steel

TC40 Gray TiC+TiN · Good balance of wear resistance and toughness

· Application: Grooving and threading of steel

TiCN

P PV720 Blackish (MEGACOAT NANO) · MEGACOAT NANO efficient machining with high quality surface finishes and superior wear and adhesion resistance.

· Application: Recommended cermet for stable steel machining and high quality surface finish

Red

Steel PV7010 Blackish TiCN · Heat-resistant MEGACOAT on improved surface cermet with excellent wear resistance and toughness

Red

PVD (Super Micro-Grain) Blackish (MEGACOAT) · Application: Stable and improved tool life in steel cutting, excellent surface finish

PV7020

· PVD TiN coating layer for improved chip evacuation and TiAlN coating sublayer provides wear resistance

(Super Micro-Grain) Red TiN+TiAlN · Application: High speed machining with long tool life

PV7025 Blackish TiCN · MEGACOAT on the super micro-grain cermet

(Super Micro-Grain) Red (MEGACOAT) · Application: High strength and long life given by MEGACOAT.

CA510

CA5-series P05 CA515

Conventional

CVD COATED CARBIDE GRADE FOR STEEl Wear Resistance Coated Carbide Coated Carbide CA525 CA530

P15

Conventional

P25

new innovations in steel Machining Coated Carbide P35

Conventional

Conventional

with CA5 Series grades & P Series Chipbreakers Coated Carbide

Stability