Page 721 - All Industrial Tool Supply | General Catalog

P. 721

Knurls • TURNING

719

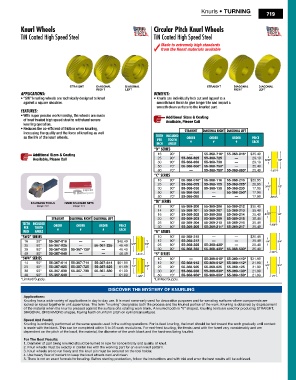

Knurl Wheels Circular Pitch Knurl Wheels

TiN Coated High Speed Steel TiN Coated High Speed Steel

Made to extremely high standards

from the finest materials available

STRAIGHT DIAGoNAl DIAGoNAl STRAIGHT DIAGoNAl DIAGoNAl

RIGHT lefT RIGHT lefT

APPLICATIONS: BeNeFITS:

• “SW” knurling wheels are technically designed to knurl • Knurls are individually hob cut and lapped to a

against a square shoulder. smooth hard finish to give longer life and impart a

smooth clean surface to the knurled part.

FeATureS:

• With super precise workmanship, the wheels are made Additional Sizes & Coating

of heat treated high speed steel to withstand severe Available, Please Call

knurling operation.

• Reduces the co-efficient of friction when knurling,

increasing the quality and the force of knurling as well Straight Diagonal right Diagonal left

as the life of the knurl wheels. teeth inCluDeD orDer orDer orDer PriCe

Per tooth

inCh angle # # # eaCh

“D” SerieS

Additional Sizes & Coating 16 90° — 55-368-716* 55-368-816* $25.49

Available, Please Call 25 90° 55-368-625 55-368-725 — 29.19 3/16" 1/2"

30 90° 55-368-630 55-368-730 — 29.19

50 70° 55-368-650* 55-368-750* — 25.49

80 70° — 55-368-780* 55-368-880* 25.49 .157"

“C” SerieS

16 90° 55-368-016* 55-368-116 55-368-216 $20.95

25 90° 55-368-025 55-368-125 55-368-225* 20.95 3/16" 1/2"

30 90° 55-368-030 55-368-130 55-368-230 17.99

50 90° 55-368-050 — 55-368-250* 17.99

80 70° 55-368-080 — — 17.99 3/16"

“M” SerieS

KNURlING ToolS HAND KNURleR SeTS

PAGE 722 PAGE 721 12 90° 55-369-200 55-369-206 55-369-212 $35.49

14 90° 55-369-201 55-369-207 55-369-213 35.49

16 90° 55-369-202 55-369-208 55-369-214 35.49 5/16" 1.0"

Straight Diagonal right Diagonal left 20 90° 55-369-203 55-369-209 55-369-215 35.49

teeth inCluDeD orDer orDer orDer PriCe 25 90° 55-369-204 55-369-210 55-369-216 35.49 .236"

Per tooth 30 90° 55-369-205 55-369-211* 55-369-217 35.49

inCh angle # # # eaCh “r” SerieS

“SW2” SerieS 10 90° 55-368-310 — — $25.49

16 90° 55-367-016 — — $46.49 12 90° 55-368-312 — — 25.49 1/4" 3/4"

25 90° 55-367-025 — 55-367-225 46.49 1/2" 1/4" 25 90° 55-368-325 55-368-425* — 25.49

30 90° 55-367-030 55-367-130* — 46.49 30 90° 55-368-330 55-368-430* 55-368-530* 25.49

40 90° 55-367-040 — — 46.49 1/4" “S” SerieS .197"

“SW4” SerieS 10 90° — 55-369-010* 55-369-110* $21.99

14 90° 55-367-614 55-367-714 55-367-814 $61.99 12 90° 55-368-912 55-369-012* 55-369-112* 21.99 1/4" 3/4"

25 90° 55-367-625 55-367-725 55-367-825 61.99 1.0" 1/2" 25 90° 55-368-925 55-369-025 55-369-125 21.99

30 90° 55-367-630 55-367-730 55-367-830 61.99 30 90° 55-368-930 55-369-030* 55-369-130* 21.99

40 90° 55-367-640 — — 61.99 3/8" 50 70° 55-368-950* 55-369-050* 55-369-150* 21.99 1/4"

*Limited Supply. *Limited Supply.

DIScoveR THe MySTeRy of KNURlING

Applications:

Knurling has a wide variety of applications in day to day use. It is most commonly used for decorative purposes and for serrating surfaces where components are

locked or keyed together in unit assemblies. The term “knurling” designates both the process and the knurled portion of the work. Knurling is obtained by displacement

of the material when the knurl is pressed against the surface of a rotating work blank. A knurled tooth is “V” shaped. Knurling tools are used for producing STRAIGHT,

DIAGONAL OR DIAMOND shapes, having teeth of uniform pitch on cylindrical surfaces.

Speed And feeds:

Knurling is ordinarily performed at the same speeds used in the cutting operations. For in-feed knurling, the knurl should be fed toward the work gradually until contact

is made with the blank. This can be completed within 5 to 25 work revolutions. For end-feed knurling, the feeds used with the turret vary considerably and are

dependent on the pitch of the knurl, the material, the diameter of the work blank and the hardness being knurled.

for The Best Results:

1. Diameter of part being knurled should be turned to size for concentricity and quality of knurl.

2. Knurl wheels must be exactly in center line with the working part for an even knurl pattern.

3. Knurl wheels are to run freely and the knurl pin must be secured on the tool holder.

4. Use heavy flow of coolant to keep the knurl wheels cool and clean.

5. There is not an exact formula for knurling. Before starting production, follow the instructions and with trial and error the best results will be achieved.