Page 492 - Ceratizit Catalog

P. 492

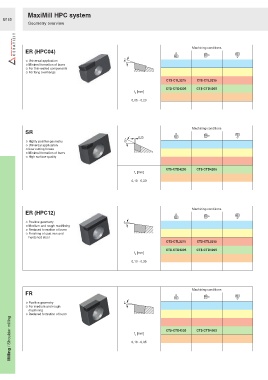

MaxiMill HPC system

B165

Geometry overview

Machining conditions

ER (HPC04)

○ Universal application 15°

○ Minimal formation of burrs

○ For thin-walled components

○ For long overhangs

CT$-CTL3215 CT$-CTL3215

CT$-CTD4205 CT$-CTD4205

f z [mm]

0,05 - 0,20

Machining conditions

SR

0,15

25°

○ Highly positive geometry

○ Universal applicaiton

○ Low cutting forces

○ Minimal formation of burrs

○ High surface quality

CT$-CTD4205 CT$-CTD4205

f z [mm]

0,10 - 0,30

Machining conditions

ER (HPC12)

○ Positive geometry 8°

○ Medium and rough machining

○ Reduced formation of burrs

○ Finishing of cast iron and

hardened steel

CT$-CTL3215 CT$-CTL3215

CT$-CTD4205 CT$-CTD4205

f z [mm]

0,10 - 0,35

Machining conditions

FR

○ Positive geometry 8°

○ For medium and rough

machining

○ Reduced formation of burrs

Milling / Shoulder milling 0,10 - 0,35 CT$-CTD4205 CT$-CTD4205

f z [mm]