Page 629 - Ceratizit Catalog

P. 629

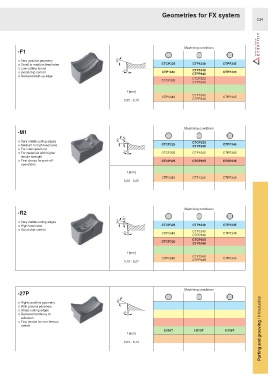

Geometries for FX system

C24

Machining conditions

-F1

25°

○ Very positive geometry

○ Small to medium feed rates CTCP325 CTP1340 CTPP345

○ Low cutting forces

7° CTP1340

○ Good chip control CTP1340 CTPP345

CTPP345

○ Reduced built-up edge

CTCP325

CTCP325

CTP1340

f [mm]

CTP1340

CTP1340 CTPP345

0,05 - 0,15 CTPP345

Machining conditions

-M1

26° 12°

○ Very stable cutting edges CTCP335

○ Medium to high feed rates CTCP325 CTP1340 CTPP345

○ For interrupted cut

○ For materials with higher 7° CTCP335 CTP1340 CTPP345

tensile strength

○ First choice for part-off CTCP325 CTCP325 CTCP335

operations

f [mm]

CTP1340 CTP1340 CTPP345

0,08 - 0,20

Machining conditions

-R2

12°

○ Very stable cutting edges 24°

○ High feed rates CTCP325 CTP1340 CTPP345

○ Good chip control

CTP1340 CTPP345

7° CTP1340

CTPP345

CTCP325

CTCP325

CTP1340

f [mm]

CTP1340

CTP1340 CTPP345

0,10 - 0,27 CTPP345

Machining conditions

-27P

25°

○ Highly positive geometry

○ With ground periphery

○ Sharp cutting edges

7°

○ Reduced tendency to

adhesion

○ First choice for non-ferrous

metals

H216T H216T H216T Parting and grooving / Introduction

f [mm]

0,03 - 0,13