Page 236 - Parlec Catalog

P. 236

Precision Finish Boring System

234 Finish Boring Speeds

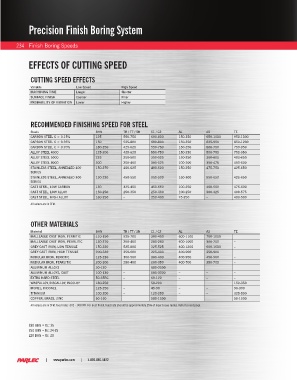

EFFECTS OF CUTTING SPEED

CUTTING SPEED EFFECTS

Variable Low Speed High Speed

MACHINING TIME Longer Shorter

SURFACE FINISH Coarser Finer

PROBABILITY OF VIBRATION Lower Higher

RECOMMENDED FINISHING SPEED FOR STEEL

Steels BHN TR / TT / SN C1 / C2 AL AS TE

CARBON STEEL C = 0.15% 125 550-750 600-800 150-350 650-1000 950-1300

CARBON STEEL C = 0.35% 150 525-800 600-800 150-350 625-950 850-1200

CARBON STEEL C = 0.70% 180-250 425-625 550-750 150-250 500-750 750-950

ALLOY STEEL 4000 125-200 425-625 550-750 150-250 500-750 750-950

ALLOY STEEL 5000 225 250-500 350-525 150-250 300-600 400-650

ALLOY STEEL 8000 300 200-400 300-525 100-200 350-475 400-500

STAINLESS STEEL, ANNEALED 400 150-270 400-625 400-600 150-250 475-750 425-650

SERIES

STAINLESS STEEL, ANNEALED 300 150-220 450-550 350-500 150-300 550-650 425-650

SERIES

CAST STEEL, LOW CARBON 150 325-450 450-650 100-250 400-550 475-600

CAST STEEL, LOW ALLOY 150-250 250-350 250-400 100-250 300-425 400-575

CAST STEEL, HIGH ALLOY 160-250 – 250-400 75-250 – 400-500

All values are in SFM.

OTHER MATERIALS

Material BHN TR / TT / SN C1 / C2 AL AS TE

MALLEABLE CAST IRON, FERRITIC 110-150 525-700 300-450 600-1100 700-1000 –

MALLEABLE CAST IRON, PEARLITIC 150-270 250-400 200-250 600-1000 300-750 –

GREY CAST IRON, LOW TENSILE 150-220 525-800 325-525 400-1200 600-1600 –

GREY CAST IRON, HIGH TENSILE 200-330 350-600 225-400 400-900 350-900 –

NODULAR IRON, FERRITIC 125-230 300-500 300-400 400-950 450-900 –

NODULAR IRON, PEARLITIC 200-300 250-400 200-350 400-700 350-700 –

ALUMINUM ALLOYS 30-120 – 600-3000 – – –

ALUMINUM ALLOYS, CAST 100-130 – 600-3000 – – –

EXTRA HARD STEEL 50-65RC – 60-120 – – –

WASPALLOY, DISCALLOY, INCOLOY 180-250 – 50-200 – – 150-350

MONEL, INCONEL 125-250 – 45-90 – – 90-300

TITANIUM 100-200 – 120-250 – – 325-500

COPPER, BRASS, ZINC 50-150 – 500-1000 – – 50-1500

All values are in SFM. Feed rates .002 - .008 IPR. For best finish, feed rate should be approximately 25% of insert nose radius. Refer to next page.

330 BHN = Rc: 35

250 BHN = Rc: 24-25

220 BHN = Rc: 20

| www.parlec.com | 1-800-866-5872