Page 1024 - Tungaloy Catalog

P. 1024

Technical Reference

Turning Tools

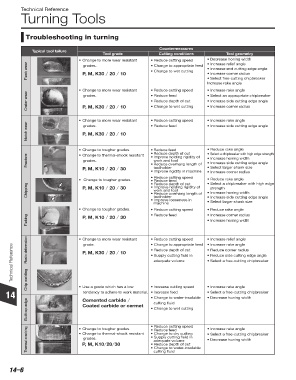

Troubleshooting in turning

Countermeasures

Typical tool failure

Tool grade Cutting conditions Tool geometry

• Change to more wear resistant • Reduce cutting speed • Decrease honing width

• Increase relief angle

Flank wear P, M, K30 / 20 / 10 • Change to wet cutting • Increase end cutting edge angle

grades.

• Change to appropriate feed

• Increase corner radius

• Select free-cutting chipbreaker

Increase rake angle

• Change to more wear resistant • Reduce cutting speed • Increase rake angle

Crater wear P, M, K30 / 20 / 10 • Reduce depth of cut • Increase side cutting edge angle

• Reduce feed

grades.

• Select an appropriate chipbreaker

• Change to wet cutting

• Increase corner radius

• Change to more wear resistant • Reduce cutting speed • Increase rake angle

Notch wear P, M, K30 / 20 / 10

• Reduce feed

grades.

• Increase side cutting edge angle

• Change to tougher grades. • Reduce feed • Reduce rake angle

• Reduce depth of cut

• Select a chipbreaker with high edge strength

Fracture • Change to thermal-shock resistant • Improve holding rigidity of • Increase honing width

grades.

work and tool

• Increase side cutting edge angle

• Reduce overhang length of

P, M, K10 / 20 / 30 toolholder • Select larger shank size

• Improve rigidity in machine • Increase corner radius

• Reduce cutting speed

• Change to tougher grades. • Reduce feed • Reduce rake angle

• Select a chipbreaker with high edge

• Reduce depth of cut

Chipping P, M, K10 / 20 / 30 • Improve holding rigidity of • Increase honing width

strength

work and tool

• Reduce overhang length of

toolholder

• Improve looseness in • Increase side cutting edge angle

machine • Select larger shank size

• Change to tougher grades. • Reduce cutting speed • Reduce rake angle

Flaking P, M, K10 / 20 / 30 • Reduce feed • Increase corner radius

• Increase honing width

• Reduce cutting speed

• Change to more wear resistant

• Increase relief angle

grade.

Technical Reference Plastic deformation P, M, K30 / 20 / 10 • Change to appropriate feed • Increase rake angle

• Reduce corner radius

• Reduce depth of cut

• Supply cutting fluid in

• Reduce side cutting edge angle

adequate volume

• Select a free-cutting chipbreaker

14 Chip welding • Use a grade which has a low • Increase cutting speed • Increase rake angle

tendency to adhere to work material. • Increase feed

• Select a free-cutting chipbreaker

• Change to water-insoluble

• Decrease honing width

Cemented carbide /

Built-up edge Coated carbide or cermet cutting fluid

• Change to wet cutting

• Reduce cutting speed • Increase rake angle

Thermal cracking • Change to thermal-shock resistant • Change to dry cutting • Select a free-cutting chipbreaker

• Change to tougher grades.

• Reduce feed

• Supply cutting fluid in

grades.

• Decrease honing width

adequate volume

P, M, K10/20/30

• Reduce depth of cut

• Change to water-insoluble

cutting fluid

14–6