Page 1025 - Tungaloy Catalog

P. 1025

Technical Reference

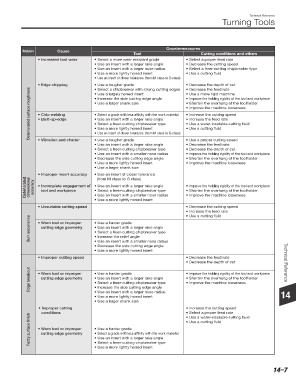

Turning Tools

Countermeasures

Problem Cause

Tool Cutting conditions and others

• Increased tool wear • Select a more wear resistant grade • Select a proper feed rate

• Use an insert with a larger rake angle • Decrease the cutting speed

• Use an insert with a larger nose radius • Select a freer-cutting chipbreaker type

• Use a more lightly honed insert • Use a cutting fluid

• Use an insert of closer tolerance. (from M class to G class)

• Edge chipping • Use a tougher grade • Decrease the depth of cut

• Select a chipbreaker with strong cutting edges

Deteriorated surface roughness • Chip welding • Use a larger shank size • Shorten the overhang of the toolholder

• Decrease the feed rate

• Use a more rigid machine

• Use a largely honed insert

• Increase the side cutting edge angle

• Improve the holding rigidity of the tool and workpiece

• Improve the machine looseness

• Select a grade with less affinity with the work material

• Increase the cutting speed

• Use an insert with a larger rake angle

• Increase the feed rate

• Built-up-edge

• Select a freer-cutting chipbreaker type

• Use a water-insoluble cutting fluid

• Use a more lightly honed insert

• Use a cutting fluid

• Use an insert of closer tolerance. (from M class to G class)

• Use a tougher grade

• Vibration and chatter

• Use an insert with a larger rake angle • Use a proper cutting speed

• Decrease the feed rate

• Select a freer-cutting chipbreaker type • Decrease the depth of cut

• Use an insert with a smaller nose radius • Improve the holding rigidity of the tool and workpiece

• Decrease the side cutting edge angle • Shorten the overhang of the toolholder

• Use a more lightly honed insert • Improve the machine looseness

• Use a larger shank size

• Improper insert accuracy • Use an insert of closer tolerance

Deteriorated dimensional accuracy • Incomplete engagement of • Use an insert with a larger rake angle • Improve the holding rigidity of the tool and workpiece

(from M class to G class)

• Shorten the overhang of the toolholder

• Select a freer-cutting chipbreaker type

tool and workpiece

• Use an insert with a smaller nose radius

• Use a more lightly honed insert • Improve the machine looseness

• Unsuitable cutting speed • Decrease the cutting speed

• Increase the feed rate

• Use a cutting fluid

Burr occurrence • Worn tool or improper • Use a harder grade

• Use an insert with a larger rake angle

cutting edge geometry

• Select a freer-cutting chipbreaker type

• Increase the relief angle

• Use an insert with a smaller nose radius

• Decrease the side cutting edge angle

• Use a more lightly honed insert

• Improper cutting speed • Decrease the feed rate

• Decrease the depth of cut Technical Reference

Edge breakout • Worn tool or improper • Use a harder grade • Improve the holding rigidity of the tool and workpiece

• Use an insert with a larger rake angle

cutting edge geometry

• Shorten the overhang of the toolholder

• Select a freer-cutting chipbreaker type

• Improve the machine looseness

• Increase the side cutting edge angle

• Use an insert with a larger nose radius

• Use a more lightly honed insert 14

• Use a larger shank size

• Improper cutting • Increase the cutting speed

conditions • Select a proper feed rate

Fuzzy surface finish • Worn tool or improper • Use a harder grade • Use a cutting fluid

• Use a water-insoluble cutting fluid

• Select a grade with less affinity with the work material

cutting edge geometry

• Use an insert with a larger rake angle

• Select a freer-cutting chipbreaker type

• Use a more lightly honed insert

14–7