Page 215 - Tungaloy Catalog

P. 215

Super lightweight, all PCD-tipped TAC Mills

DPD09∙EDPD09

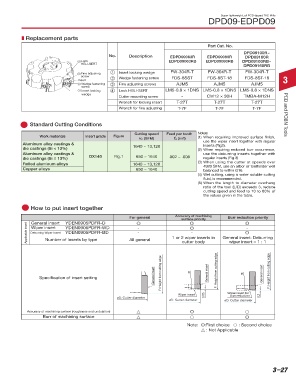

Replacement parts

Part Cat. No.

DPD09100R~

No. Description EDPD09063R EDPD09080R DPD09160R

r Lock EDPD09063RB EDPD09080RB DPD09100RB~

HELI-SERT

DPD09160RB

e Fine adjusting a Insert locking wedge FW-304R-T FW-304R-T FW-304R-T

screw FDS-8SST FDS-8ST-18 FDS-8ST-18

Insert b Wedge fastening screw 3

w Wedge fastening c Fine adjusting screws AJM5 AJM5 AJM5

screw

q Insert locking d Lock HELI-SERT LM5-0.8 × 1DNS LM5-0.8 × 1DNS LM5-0.8 × 1DNS

wedge

Cutter mounting screw - CM12 × 30H TMBA-M12H

Wrench for locking insert T-27T T-27T T-27T

Wrench for fine adjusting T-7F T-7F T-7F PCD and PCBN Tools

Standard Cutting Conditions

Cutting speed Feed per tooth Notes:

Work materials Insert grade Figure (1) When requiring improved surface finish,

vc (SFM) fz (in/t)

Aluminum alloy castings & 1640 ~ 13,120 use the wiper insert together with regular

inserts (Fig2).

die castings (Si < 13%) (2) When requiring reduced burr occurrence,

Aluminum alloy castings & use the deburring inserts together with

die castings (Si ≥ 13%) DX140 Fig.1 650 ~ 1640 .002 ~ .008 regular inserts (Fig.3)

Rolled aluminum alloys 1640 ~ 13,120 (3) When using the cutter at speeds over

4920 SFM, use an arbor or toolholder well

Copper alloys 650 ~ 1640 balanced to within G16.

(4) Wet cutting, using a water soluble cutting

fluid, is recommended.

(5) When the length to diameter overhang

ratio of the tool (L/D) exceeds 3, reduce

cutting speed and feed to 70 to 80% of

the values given in the table.

How to put insert together

For general Accuracy of machining Burr reduction priority

surface priority

General insert

YDEN0905PDFR-D

Applicable insert Deburring Wiper Insert YDEN0905PDFR-WD All general 1 or 2 wiper inserts in General insert: Deburring

Wiper insert

-

-

YDEN0905PDFR-BD

-

-

Number of Inserts by type

wiper insert = 1 : 1

cutter body

General insert F: Height from cutting edge R General insert F: Height from cutting edge R General insert F: Height from cutting edge

Specification of insert setting

Wiper insert 0.05 Wiper insert for

burr reduction

øD: Cutter diameter 0.2

øD: Cutter diameter øD: Cutter diameter

Accuracy of machining surface (roughness and undulation) n s

Burr of machining surface n s

Note: :First choice s : Second choice

n : Not Applicable

: Stocked items.

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

3–27