Page 219 - Tungaloy Catalog

P. 219

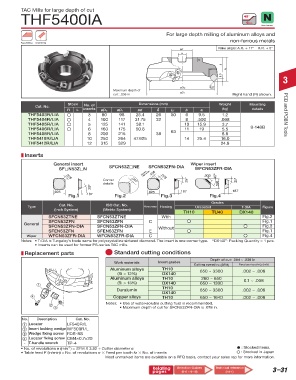

TAC Mills for large depth of cut

THF5400IA 45°

6mm

Non-ferrous

For large depth milling of aluminum alloys and

non-ferrous metals

Face Milling Chamfering

ød Rake angle: A.R. 17° R.R. 5°

a

b

R

Lf

8.0

3

øDc 45º

Maximum depth of

cut : .236 in øD1 Right hand (R) shown.

Stock Dimensions (mm) Weight Mounting

Cat. No. No. of

R L inserts øDc øD1 ød R Lf b a (kg) details

THF5403R/LIA 3 80 98 25.4 26 50 6 9.5 1.2 PCD and PCBN Tools

THF5404R/LIA 4 100 117 31.75 32 8 .500 .098

THF5405R/LIA 5 125 141 38.1 10 15.9 3.7

THF5406R/LIA 6 160 175 50.8 11 19 5.5 9-148B

THF5408R/LIA 8 200 215 38 63 8.8

THF5410R/LIA 10 250 264 47.625 14 25.4 16.0

THF5412R/LIA 12 315 329 24.9

Inserts

General insert Wiper insert

SFhN53ZhN SFCN53ZhNE SFCN53ZFN-DIA WFCN53ZFR-DIA

edge length

Effective .106 .303

.078

Corner .047 .078 25º 45º 25º

details .598

25º

.625 .625 .187 .187

Fig.1 .187 Fig.2 Fig.3 Fig.4

Grades

Cat. No. ISO Cat. No.

Type Accuracy Honing Uncoated T-DIA Figure

(Inch System) (Metric System)

TH10 TU40 DX140

SFCN53ZTNE SFCN53ZTNE With Fig.2

SFCN53ZFN SFCN53ZFN C d Fig.1

General

SFCN53ZFN-DIA SFCN53ZFN-DIA Without d Fig.3

SFEN53ZFN SFEN53ZFN E d Fig.1

Wiper WFCN53ZFR-DIA WFCN53ZFR-DIA C d Fig.4

Notes: • T-DIA is Tungaloy’s trade name for polycrystalline sintered diamond. The insert is one-corner type. “DX140”: Packing Quantity = 1 pcs.

• Inserts can be used for former PS-series TAC mills.

Replacement parts Standard cutting conditions

Depth of cut: .004 ~ .236 in

Work materials Insert grades

Cutting speed vc (SFM) Feed per tooth f z (in/t)

Aluminum alloys TH10 650 ~ 3300 .002 ~ .008

(Si < 12%) DX140

Aluminum alloys TH10 260 ~ 650 0.1 ~ .008

(Si > 13%) DX140 650 ~ 1300

1

Duralumin TH10 650 ~ 3300 .002 ~ .008

DX140

4 Copper alloys TH10 650 ~ 1640 .002 ~ .008

Notes: • Use of water-soluble cutting fluid is recommended.

2

3 • Maximum depth of cut for SFCN53ZFN-DIA is .078 in.

No. Description Cat. No.

a Locator LF540R/L

b Insert locking wedge WF500R/L

c Wedge fixing screw FDS-8S

d Locator fixing screw CM4×0.7×20

- T-handle wrench TP-4

-1

• No. of revolutions n (min ) = SFM X 3.82 ÷ Cutter diameter ø : Stocked items.

• Table feed F (in/min) = No. of revolutions n Feed per tooth fz No. of inserts : Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

Relating Selection Guides Technical reference 3–31

pages (9-6 ~ 9-18) (14-1)