Page 299 - Tungaloy Catalog

P. 299

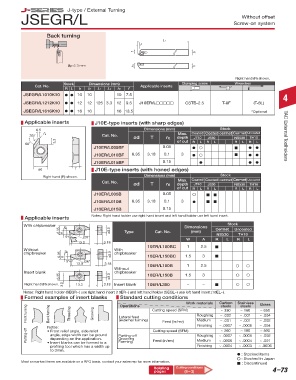

J-type / External Turning

JSEGR/L Screw-on system

Without offset

Back turning

L1

L2

f b

ap ≤ 3 mm h1 h

Dimensions (in) Applicable Clamping Screws Wrench B41 Right hand (R) shown.

Cat. No. inserts Stock Dimensions (mm) Clamping screw Wrenches

R L h b L1 L2 h1 f C Cat. No. R L h b L1 L2 h1 f Applicable inserts

JSTBR/L063 d d 0.375 0.375 0.375 0.250 0.200 JSEGR/L1010K10 d d 10 10 10 7.5

JSTBR/L083 d d 0.500 0.500 5 0.59 0.500 0.375 0.120 JTBR/L3*** CSTB-4SD T-8F (T-8L) 4

JSTBR/L103 d d 0.625 0.625 0.625 0.500 - JSEGR/L1212K10 d d 12 12 125 3.3 12 9.5 J10ER/L CSTB-2.5 T-8F (T-8L)

JSEGR/L1616K10 d d 16 16 16 13.5 *Optional

Dimensions (mm) Clamping Screws Wrench

Cat. No. Applicable Applicable inserts

R L h b L1 L2 h1 f C inserts J10E-type inserts (with sharp edges)

Stock

JSTBR/L1010K3 d d 10 10 10 6 5 0.5 Dimensions (mm) Max. Coated Coated cermet Cermet Uncoated

JSTBR/L1212K3 d d 12 12 125 15 12 8 3 JTBR3¨¨¨ CSTB-4SD T-8F - 30˚ r ε Cat. No. ød T rε depth J740 J530 NS530 TH10 TAC External Toolholders

JSTBR/L1616K3 d d 16 16 16 12 - 60˚ 3.3 of cut R L R L R L R L

J10ER/L005BF 0.05 d d d

J10ER/L010BF 6.35 3.18 0.1 3 d d d

J10ER/L015BF 0.15 d d d

ød T J10E-type inserts (with honed edges)

Right hand (R) shown. Dimensions (mm) Stock

Max.

Cat. No. ød T rε depth Coated Coated cermet Cermet Uncoated

J740

J530

NS530

TH10

of cut R L R L R L R L

J10ER/L005B 0.05

J10ER/L010B 6.35 3.18 0.1 3 d

J10ER/L015B 0.15

Applicable inserts Notes: Right hand holder use right hand insert and left hand holder use left hand insert.

W

6.35 6.35 A 5° W 26° ø3.0ø3.0 Type Cat. No. Dimensions Cermet Uncoated

With chipbreaker 6.35 W ø3.0 Stock

A A

(mm)

26°

5°

5° 13.0 26° 3.18 W A NS530 R TH10 L

13.0

3.18

L

R

13.0 3.18

10ER/L100BC 1 2.5

Without W

chipbreaker 6.35 W ø3.0 With

chipbreaker

6.35 6.35 A 5° W 13.0 26° ø3.0ø3.0 10ER/L150BC 1.5 3

A A

5°

26°

3.18

5° 13.0 26° 3.18 10ER/L100B 1 2.5

13.0 3.18 Without

Insert blank chipbreaker

6.35 ø3.0ø3.0 ø3.0 10ER/L150B 1.5 3

3.18 Insert blank

Right hand (R) shown. 6.35 6.35 3.0 13.3 3.18 10ER/L300 - -

13.3

3.0 3.0

3.18

13.3

Notes: Right hand holder (SEGR~) use right hand insert (10ER~) and left hand holder (SEGL~) use left hand insert (10EL~).

Formed examples of insert blanks Standard cutting conditions

Work materials Carbon Stainless Brass

steels

Operations

steels

Front turning Back turning Threading Grooving Lateral feed Cutting speed (SFM) Roughing ~ .002 ~ .001 ~ .004

~ 160

~ 650

~ 330

(external turning)

~ .001

~ .001

~ .002

Medium

Feed (in/rev)

Notes: Cutting speed (SFM) Finishing ~ .0007 ~ .0006 ~ .004

Parting-off angle, edge width can be ground Parting-off Feed (in/rev) Roughing ~ .0007 ~ .0006 ~ .002

~ 260

~ 100

~ 500

• Front relief angle, side relief

Grooving

depending on the application.

~ .0006

~ .001

Medium

~ .0004

• Insert blanks can be formed to a

profiling tool which has a width up Forming Finishing ~ .0004 ~ .0003 ~ .0006

to 3mm.

d : Stocked items

: Stocked items.

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. : Discontinued

: Stocked in Japan

Relating Parts Relating Cutting conditions 4–73

pages (13-1~) pages (8-3)