Page 300 - Tungaloy Catalog

P. 300

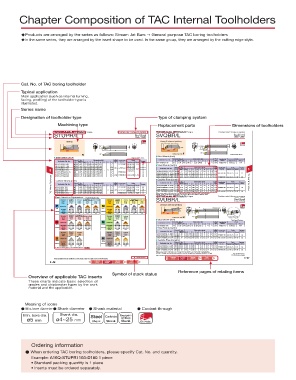

Chapter Composition of TAC Internal Toolholders

uProducts are arranged by the series as follows: Stream Jet Bars g General purpose TAC boring toolholders

uIn the same series, they are arranged by the insert shape to be used. In the same group, they are arranged by the cutting edge style.

Cat. No. of TAC boring toolholder

Typical application

Main application (such as internal turning,

facing, profiling) of the toolholder type is

illustrated.

Series name

Designation of toolholder type Type of clamping system

Machining type Replacement parts Dimensions of toolholders

S-type Positive rake / Screw-on system S-type Positive rake / Screw-on system

STUPR/L Steel Carbide SVQBR/L Steel Carbide

Shank

Shank

Shank

Shank

Boring Boring & internal profiling

ØDm h Oil Hole ØDm h

95° 117.5° Oil Hole

ØDs 25.5˚ ØDs

f f f2

f2 L2 L1 L2 L1

α α θ

U θ Cutting edge style F Right hand (R) shown.

Steel Shank (inch) Right hand (R) shown. Steel Shank (inch) Std.

Min

radius

Std.

Min Dimensions (IN) corner Applicable Parts Toolholder Cat. No. Stock bore.dia Dimensions (in) corner Applicable Parts

inserts

Stock bore.dia.

Toolholder Cat. No. radius inserts Torque R L ØDm ØDs f L1 L2 h f2 θ α rε Clamping screw Wrench

R L ØDm ØDs f L1 L2 h f2 θ α rε Clamping screw Wrench A10-SVQBR2-D16 1.00 .625 .500 7 1.25 .600 - -5 -6 .016 VBoo1103 CSTB-2.5 T-8F

A05-STUPR/L7-D07 .438 .313 .250 5.00 .625 2.88 -7˚ TPoo0902 CSTB-2.2S T-7F 0.9 Steel Shank (metric)

A06-STUPR/L2-D08 .500 .375 .281 5.00 .750 .350 -5˚ CSTB-2.5S 1.2 Min Dimensions (mm) Std. Parts

A08-STUPR/L2-D11 .688 .500 .406 5.00 1.00 .475 -3˚ .016 TPoo1102 CSTB-2.5B 1.2 Toolholder Cat. No. Stock bore.dia. corner Applicable Torque 5

radius

5 A10-STPUR/L2-D14 .875 .625 .531 7.00 1.25 .600 - 5˚ -2˚ CSTB-2.5 T-8F 1.4 A12M-SVQBR/L11-D170 R L ØDm ØDs 12 10.5 150 L1 L2 24 11 h 4.5 f2 -5˚ θ -10˚ α 0.4 rε inserts Clamping screw Wrench (N·m)

f

17

A10-STUPR/L2.5-D14 .875 .625 .531 7.00 1.25 .600 -2˚ TPoo1103 1.4 A16Q-SVQBR/L11-D215 21.5 16 13 180 30 15 5 -5˚ -8˚ 0.4 VBoo1103 CSTB-2.5 T-8F 1.2

A12-STUPR/L3-D16 1.00 .750 .594 7.00 1.437 .725 -2˚ 0˚ .032 TPoo16T3 CSTB-4M T-15F 1.4 3.0 A20R-SVQBR/L11-D255 25.5 20 25 17.5 250 36 45 18 23 5 5 -5˚ -5˚ -6˚ -8˚ 0.4 0.8 VBoo1604 CSTB-3.5 T-15F 3.0

15

200

A16-STUPR/L3-D20

TAC Internal Toolholders Carbide Shank (inch) R L ØDm ØDs f L1 Dimensions (IN) f2 θ -7˚ -5˚ α corner Applicable Clamping screw Wrench Torque E12Q-SVQBR/L11-D170 Stock L bore.dia. ØDs 12 16 20 10.5 180 L1 Dimensions (mm) 4.5 f2 5 5 -5˚ -5˚ -5˚ θ -10˚ α corner rε VBoo1103 Clamping screw Wrench Torque TAC Internal Toolholders

1.25

1.00 .688 7.00 1.75 .975

30.5

A25S-SVQBR/L16-D305

Carbide Shank (metric)

Std.

Min

Parts

Applicable

Toolholder Cat. No.

Std.

inserts

(N·m)

radius

Min

Parts

h

ØDm

f

L2

R

Stock bore.dia.

Toolholder Cat. No.

inserts

radius

27

0.4

h

17

L2

11

rε

T-8F

E16R-SVQBR/L11-D215

E05-STUPR7-D07

21.5

.313 .250 5.00 .625 2.88

32

1.2

0.4

200

0.9

-8˚

13

CSTB-2.5

TPoo0902 CSTB-2.2S T-7F

.438

15

E06-STUPR2-D08

CSTB-2.5S

250

15

0.4

-6˚

.500

1.2

25.5

36

E20S-SVQBR/L11-D255

18

.375 .281 5.00 .750 .350

.016 TPoo1102

T-8F

5˚

-

25

17.5 300

CSTB-2.5B

23

45

E08-STUPR2-D11

E25T-SVQBR/L16-D305

5

-3˚

.500 .406 5.00 1.00 .475

30.5

1.2

.688

T-9F

1.4

When using a right or left hand insert, the right hand insert (R) is used for the left hand toolholders

.625 .531 7.00 1.25 .600

.875

-2˚

CSTB-3

E10-STUPR2.5-D14

TPoo1103

(SVQBL type), and the left hand insert (L) is used for the right hand toolholders (SVQBR type). -5˚ -8˚ 0.8 VBoo1604 CSTB-3.5 T-15F 3.0

S-type Positive rake / Screw-on system

Basic Selection Chipbreakers TPoo1102oo-oo

Precision Finishing to Precision Finishing to SVUBR/L Steel Carbide

Operation finishing Finishing medium cutting Medium cutting Operation finishing Finishing medium cutting Medium cutting Shank Shank

Grade NS9530 AH725 T9115 T9125 Grade GH330 AH725 AH725 T6130

Page 2-123 2-123 2-125 2-128 Page 2-124 2-123 2-126 2-128

01 PSF PS PM W15 PSF PSS PM

Boring & internal profiling

Chipbreaker Chipbreaker ØDm h

Steel Stainless 50˚ L2 Clamping screw Oil Hole

Vc (SFM) (500-800) (170-600) (400-800) (400-800) Vc (SFM) (100-150) (150-600) (150-600) (250-400)

Continuous ap (in) (.001-.006) (.005-.030) (.010-.060) (.040-.118) Continuous ap (in) (.001-.080) (.005-.030) (.010-.060) (.040-.118) 93° f ØDs 93° ØDs

f (in/rev) (.001-.006) (.001-.006) (.002-.008) (.003-.012) f (in/rev) (.001-.006) (.001-.006) (.002-.008) (.003-.012) f2 f

rε (in) .016 .016 .032 .032 rε (in) .016 .016 .032 .032

L1 f2

Finishing to

L1

Operation Precision medium cutting Medium cutting Operation Precision Finishing U α θ Carbide Shank style

finishing

finishing

Grade BX930 T5115 T5115 Grade DX140 GH110 Cutting edge style

Page 3-14 2-130 2-131 Page 3-24 2-124 Steel Shank (inch)

T-CBN CM No chipbreaker T-DIA W15 Right hand (R) shown.

Std.

Stock Min Dimensions (in) corner Parts

Chipbreaker Chipbreaker Toolholder Cat. No. bore.dia radius Applicable

Cast lron Non-ferrous R L ØDm ØDs f L1 L2 h f2 θ α rε inserts Clamping screw Wrench

Vc (SFM) (600-1400) (450-1300) (450-1300) Vc (SFM) (800-4000) (300-3000) A12-SVUBR2-D16 1.00 .750 .594 10 1.425 .725 - -0 -6 .016 VBoo1103 CSTB-2.5 T-8F

Continuous ap (in) (.001-.006) (.001-.080) (.001-.080) Continuous ap (in) (.001-.020) (.001-.080) Steel Shank (metric)

f (in/rev) (.001-.008) (.001-.008) (.001-.008) f (in/rev) (.001-.008) (0.0.3-0.15)

rε (in) .016 .032 .032 rε (in) .016 .016 Stock Min Dimensions (mm) Std. Parts

inserts

(N·m)

radius

ØDm

Operation Precision Finishing Operation Precision Finishing Toolholder Cat. No. R L bore.dia. ØDs f L1 L2 h f2 θ α corner rε Applicable Clamping screw Wrench Torque

finishing

finishing

Grade BX470 BX950 Grade BXM10 BXM20 A16Q-SVUBR/L11-D200 20 16 15.5 180 35 15 8 0˚ -8˚ 0.4

Page 3-12 3-14 Page 3-12 3-12 VBoo1103 CSTB-2.5 T-8F 1.2

T-CBN T-CBN T-CBN T-CBN A20R-SVUBR/L11-D250 25 20 17.5 200 40 19 8 0˚ -7˚ 0.4

Chipbreaker Chipbreaker A25S-SVUBR/L16-D320 32 25 20.5 250 50 23 8.5 0˚ -6˚ 0.8 VBoo1604 CSTB-3.5 T-15F 3.0

Hard

Superalloys Materials Carbide Shank (metric)

Vc (SFM) (300-800) (230-900) Vc (SFM) (500-1100) (400-750) Stock Min Dimensions (mm) corner Parts Torque

Std.

inserts

Continuous ap (in) (.001-.006) (.005-.030) Continuous ap (in) (.001-.008) (.001-.008) Toolholder Cat. No. R L bore.dia. ØDs f L1 L2 h f2 θ α radius Applicable Clamping screw Wrench (N·m)

f (in/rev) (.001-.008) (.001-.008) f (in/rev) (.0001-.003) (.001-.006) ØDm rε

rε (in) .016 .016 rε (in) .016 .016 E16R-SVUBR/L11-D245 24.5 16 16 200 - 15 8 0˚ -8˚ 0.4

For other machining types, see “Selection System” 2-18~ E20S-SVUBR/L11-D285 28.5 20 18 250 - 19 8 0˚ -7˚ 0.4 VBoo1103 CSTB-2.5 T-8F 1.2

E25T-SVUBR/L16-D340 34 25 21 300 - 23 8.5 0˚ -6˚ 0.8 VBoo1604 CSTB-3.5 T-15F 3.0

When using a right or left hand insert, the right hand insert (R) is used for the left hand toolholders

(SVUBL oo type), and the left hand insert (L) is used for the right hand toolholders (SVUBR oo type). : Stocked items.

: Stocked in Japan

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

: Stocked items. Features Relating Sleeves Parts 5–27

Most unmarked items are available on a RFQ basis, contact your sales rep for more information. (5-6) pages (5-64~) (13-1~)

Parts

5–26 Features Relating Sleeves (13-1~)

(5-64~)

pages

(5-6)

Applicable TAC inserts

Reference pages of relating items

Symbol of stock status

Overview of applicable TAC inserts

These charts indicate basic selection of

grades and chipbreaker types by the work

material and the application.

■ Meaning of icons

d Min. bore diameter d Shank diameter d Shank material d Coolant through

Min. bore dia. Shank dia. Steel Carbide Tsuppari-

Ichiban

ø5 mm ø4~25 mm Shank Shank Shank Oli Hole

■ Ordering information

d When ordering TAC boring toolholders, please specify Cat. No. and quantity.

Example: A16Q-STUPR1103-D180 1 piece

• Standard packing quantity is 1 piece

• Inserts must be ordered separately.