Page 338 - Tungaloy Catalog

P. 338

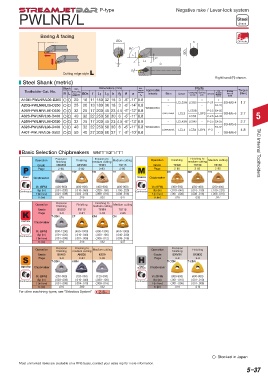

P-type Negative rake / Lever-lock system

PWLNR/L Steel

Shank

Boring & facing

ØDm h Oil Hole

95°

ØDs

f

f2

L2

rε L1

α

L θ

Cutting edge style

Right hand (R) shown.

Steel Shank (metric)

Stock Min Dimensions (mm) Std. Parts

Toolholder Cat. No. R L bore.dia. ØDs f L1 L2 h f2 θ α corner Applicable Shim Lever Clamping Spring Wrench supply Screw Torque

Oil

radius

inserts

(N·m)

for oil

ØDm

attach-

pin

rε

screw

A16M-PWLNR/L06-D200 20 16 11 150 32 15 3 -8˚ -17˚ 0.8 - - ment hole

-

LCL33N LCS33 P-2F SSHM3-4 1.7

A20Q-PWLNR/L06-D250 25 20 13 180 36 18 3 -6˚ -14˚ 0.8 - - EA-20

WNoo33o

A25R-PWLNR/L06-D320 32 25 17 200 45 23 4.5 -6˚ -12˚ 0.8 LCS3B P-2.5 EA-25

LSW312BR/L LCL3 LSP3 SSHM5-6 2.7

A32S-PWLNR/L06-D400 40 32 22 250 50 30 6 -6˚ -11˚ 0.8 LCS3 P-2.5 EA-32 5

A25R-PWLNR/L08-D320 32 25 17 200 45 23 4.5 -6˚ -13˚ 0.8 - LCL43N LCS43 - P-2.5 EA-25 SSHM5-6 2.7

A32S-PWLNR/L08-D400 40 32 22 250 50 30 6 -6˚ -11˚ 0.8 WNoo43o EA-32

LSW42BR/L LCL4 LCS4 LSP4 P-3 4.8

A40T-PWLNR/L08-D500 50 40 27 300 60 37 7 -6˚ -10˚ 0.8 - SSHM6-6

Basic Selection Chipbreakers WNuu43u-uu TAC Internal Toolholders

Operation Precision Finishing Finishing to Medium cutting Operation Finishing Finishing to Medium cutting

finishing medium cutting medium cutting

Grade NS9530 GT9530 T9115 T9115 Grade T6120 T6130 T6130

Page 2-80 2-80 2-83 2-85 Page 2-80 2-83 2-85

TF TSF TM TH SS SM TH

Steel Chipbreaker Stainless Chipbreaker

Vc (SFM) (400-800) (400-900) (400-900) (400-800) Vc (SFM) (300-550) (250-400) (250-400)

Continuous ap (in) (.001-.020) (.010-.060) (.020-.180) (.100-.220) Continuous ap (in) (.010-.040) (.010-.150) (.100-.220)

f (in/rev) (.001-.008) (.003-.010) (.008-.016) (.008-.016) f (in/rev) (.001-.008) (.008-.016) (.008-.016)

rε (in) .016 .016 .032 .047 rε (in) .016 .032 .047

Operation Precision Finishing Finishing to Medium cutting

finishing medium cutting

Grade BX930 T5115 T5115 T5115

Page 3-9 2-81 2-84 2-86

T-CBN CF CM CH

Cast lron Chipbreaker Features

(5-6)

Vc (SFM) (300-1200) (450-1300) (400-1300) (450-1300)

ap (in) (.001-.020) (.010-.040) (.020-.180) (.040-.230)

Continuous

f (in/rev) (.001-.006) (.001-.006) (.006-.012) (.008-.016)

rε (in) .016 .016 .032 .047

Finishing to

Operation Precision medium cutting Medium cutting Operation Precision Finishing

finishing

finishing

Grade BX480 AH905 KS20 Grade BXM10 BXM20

Page 3-9 2-84 2-85 Page 3-9 3-9

T-CBN HMM SA T-CBN T-CBN

Hard

Superalloys Chipbreaker Materials Chipbreaker

Vc (SFM) (230-900) (120-350) (120-300) Vc (SFM) (800-900) (400-800)

Continuous ap (in) (.003-.008) (.010-.040) (.020-.120) Continuous ap (in) (.001-.010) (.001-.010)

f (in/rev) (.001-.006) (.004-.010) (.008-.016) f (in/rev) (.001-.006) (.001-.006)

rε (in) .016 .032 .032 rε (in) .016 .016

For other machining types, see “Selection System” 2-6~

: Stocked in Japan

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

5–37