Page 416 - Tungaloy Catalog

P. 416

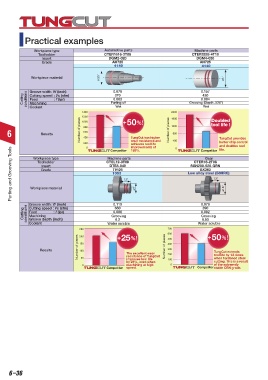

Practical examples

Workpiece type Automotive parts Machine parts

Toolholder CTER1616-2T08 CTER2525-4T10

Insert DGM2-020 DGM4-030

Grade AH725 AH725

4140 4140

Workpiece material ø.55" ø3"

Groove width: W (inch) 0.078 0.157

Cutting speed : Vc (sfm) 370 430

0.003

0.004

Cutting conditions Feed : f (ipr) Parting off Grooving (Depth .024")

Machining

Coolant

1400 Wet 2000 Wet

1200 + 50 % ! 1600 Doubled

Number of pieces 800 Number of pieces 1200 tool life !

1000

6 Results 600 0 Competitor TungCut has higher 800 0 Competitor TungCut provides

400

wear resistance and

400

better chip control

200

achieves tool life

and doubles tool

improvements of

Parting and Grooving Tools Workpiece material CTEL12-3T09 Low alloy steel (58HRC)

life.

150%.

Gear

Machine parts

Workpiece type

Toolholder

CTER16-2T08

DTE3-040

SGN200-020-QBN

Insert

BX360

Grade

T9125

1053

1.3"

1.2"

ø1.6"

ø1 "

Groove width: W (inch) 0.118 0.079

Cutting speed : Vc (sfm)

660

390

Cutting conditions Machining : f (ipr) Grooving 0.002

Feed

0.008

Grooving

Groove depth (inch)

0.03

0.2

Coolant Water soluble Water soluble

250 700

600 + 50 % !

Number of pieces 150 Number of pieces 400

200

+

25 % !

500

Results 100 The excellent wear 300 TungCut extends

tool life by 1.5 times

200

resistance of TungCut

50

improves tool life

cutting. This is a result

by 25%, even when 100 when hardened steel

0 machining at high 0 of the extremely

Competitor speed. Competitor stable CBN grade.

6–36