Page 54 - Tungaloy Catalog

P. 54

Basic Chipbreakers Negative Inserts

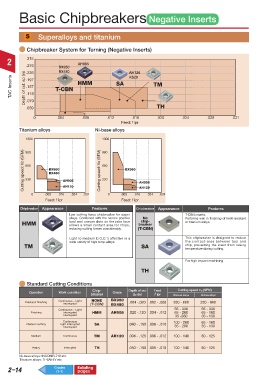

Superalloys and titanium

Chipbreaker System for Turning (Negative Inserts)

2 .315 BX950 AH905 AH120

.276

BX480

.236

TAC Inserts Depth of cut: ap (in) .197 T-CBN HMM SA KS20 TM

.157

.118

.079

.039 TH

0 .004 .008 .012 .016 .020 .024 .028 .031

Feed: f ipr

Titanium alloys Ni-base alloys

1300 1300

Cutting speed: Vc (SFM) 650 BX950 AH905 Cutting speed: Vc (SFM) 650 BX950 AH905

980

980

BX480

330

330

.024

.024

0 .008 .016 AH120 .031 0 .008 .016 AH120 .031

Feed: f ipr Feed: f ipr

Chipbreaker Appearance Features Chipbreaker Appearance Features

Low cutting force chipbreaker for super T-CBN inserts.

alloys. Combined with the narrow positive No Performs well in finishing of heat-resistant

chip-

HMM land and uneven dots on the rake face breaker or titanium alloys.

allows a small contact area for chips,

reducing cutting forces considerably. (T-CBN)

Light to medium D.O.C.’s affective in a This chipbreaker is designed to reduce

wide variety of high temp alloys. the contact-area between tool and

TM SA chip, preventing the insert from raising

temperature during cutting.

For high impact machining

TH

Standard Cutting Conditions

Chip- Depth of cut Feed Cutting speed vc (SFM)

Operation Work condition Grade

breaker ap (in) f ipr Titanium Alloys NI Base Alloys

NONE

Precision finishing Continuous ~ Light (T-CBN) BX950 .004 -.020 .002 - .008 330 - 660 230 - 980

interrupted

BX480

Continuous ~ Light 65 - 330 65 - 330

Finishing interrupted HMM AH905 .020 -.120 .004 - .012 65 - 260 65 - 160

Interrupted 35 -260 35 - 130

Continuous 100 - 260 65 - 160

Medium cutting Light interrupted SA .040 - .160 .008 - .016

Interrupted 35 - 200 35 - 130

Medium Continuous TM AH120 .004 - .125 .006 - .012 100 - 140 80 - 125

Heavy Interupted TH .050 - .160 .008 - .018 100 - 140 80 - 125

Ni-base alloys: INCONEL718 etc.

Titanium alloys: Ti-6Al-4V etc

2–14 Grades Relating

pages

(1-1)