Page 56 - Tungaloy Catalog

P. 56

Basic Chipbr

Basic Chipbreakerseakers Negative InsertsNegative Inserts

Hard Materialsd Materials

Har

Chipbr

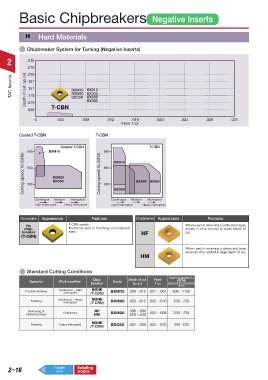

Chipbreaker System for Turning (Negative Inserts)eaker System for Turning (Negative Inserts)

2 .315

.276

.236

TAC Inserts Depth of cut: ap (in) .197 BXM10 BX310

.157

BXM20 BX330

.118

BX360

BXC50

.079

.039 T-CBN BX380

0 .004 .008 .012 .016 .020 .024 .028 .031

Feed: f ipr

Coated T-CBN-CBN

Coated T T-CBNT-CBN

Coated T-CBN T-CBN

980 BXM10 980 BX310

Cutting speed: Vc (SFM) 650 BXM20 Cutting speed: Vc (SFM) 650 BX360 BX380

BXC50

330

330

BX330

Continuous Medium interrupted Continuous Medium interrupted

Light interrupted Heavy interrupted Light interrupted Heavy interrupted

Chipbreaker Appearance Features Chipbreaker Appearance Features

No T-CBN inserts. When used in removing a carburized layer,

chip- Performs well in finishing of hardened excels in chip control at small depth of

breaker steel. HF cut.

(T-CBN)

When used in removing a carburized layer,

excels in chip control at large depth of cut.

HM

Standard Cutting Conditions

Chip- Depth of cut Feed Cutting speed vc

Operation Work condition Grade (SFM)

breaker ap (in) f ipr Hardened & pre Hardened

Steels

Continuous ~ Light NONE

Precision finishing BXM10 .002 -.012 .001 - .007 500 - 1150

interrupted (T-CBN)

NONE

Finishing Continuous ~ Heavy (T-CBN) BXM20 .002 -.012 .002 - .010 230 - 720

interrupted

Removing of HF .008 - .030

carburized layer Continuous HM BXM20 .020 - .040 .002 - .008 230 - 720

NONE

Finishing Heavy Interrupted BXC50 .002 - .020 .002 - .010 350 -720

(T-CBN)

2–16 Grades Relating

pages

(1-1)