Page 58 - Tungaloy Catalog

P. 58

Basic Chipbr

Basic Chipbreakerseakers Positive InsertsPositive Inserts

Steel

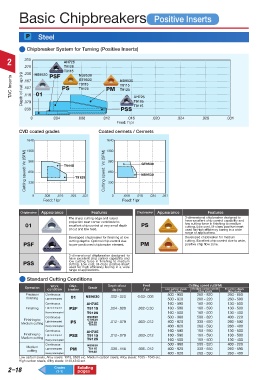

Chipbreaker System for Turning (Positive Inserts)

2 .315 AH725

.276 T9125

T9115 NS9530

.236

NS9530

PSF

TAC Inserts Depth of cut: ap (in) .197 01 PS GT9530 PM NS9530 AH725

T9115

T9115

.157

T9125

T9125

.118

.079

T9115

.039 PSS T9125

0 .004 .008 .012 .016 .020 .024 .028 .031

Feed: f ipr

CVD coated grades Coated cermets / Cermets

1640 1640

1300

1300

Cutting speed: Vc (SFM) 980 T9115 T9125 Cutting speed: Vc (SFM) 980 GT9530

650

650

NS9530

330

330

0 .008 .016 .024 .031 0 .008 .016 .024 .031

Feed: f ipr Feed: f ipr

Chipbreaker Appearance Features Chipbreaker Appearance Features

The sharp cutting edge and raised 3-dimensional chipbreaker designed to

projection near corner contribute to have excellent chip control capability and

01 excellent chip control at very small depth PS low cutting force in finishing to medium

cutting. Low cost, M-class positive insert

of cut and low feed. used for high efficiency boring in a wide

range of applications.

Developed chipbreaker for finishing at low Developed chipbreaker for medium

cutting depths. Optimal chip control due cutting. Excellent chip control due to wide,

PSF to pre-positioned chipbreaker element. PM positive chip flow zone.

3-dimensional chipbreaker designed to

have excellent chip control capability and

PSS low cutting force in finishing to medium

cutting. Low cost, M-class positive insert

used for high efficiency boring in a wide

range of applications.

Standard Cutting Conditions

Chip-

Work

Operation condition breaker Grade Depth of cut Feed Low carbon steels Cutting speed vc(SFM) Hi carbon steels

Medium carbon steels

f ipr

ap (in)

Alloy steels

Alloy steels

Alloy steels

Precision Continuous NS9530 .002-.020 0.03-.006 500 - 980 260 - 820 260 - 650

finishing Light interrupted 01 500 - 820 260 - 220 260 - 590

Continuous AH725 160 - 590 160 - 590 130 - 500

Finishing Light interrupted PSF T9115 .004-.020 .002-0.30 160 - 590 160 - 590 130 - 500

Heavy interrupted T9125 160 - 500 160 - 500 130 - 400

Continuous NS9530 500 - 980 500 - 820 400 - 220

Finishing to Light interrupted GT9530

Medium cutting PS T9115 .012-.079 .003-.012 400 - 820 330 - 650 260 - 590

T9125

Heavy interrupted 400 - 820 260 - 590 260 - 400

Continuous AH725 160 - 590 160 - 590 130 - 500

Finishing to Light interrupted PSS T9115 .012-.079 .003-.012 160 - 590 160 - 590 130 - 500

Medium cutting T9125

Heavy interrupted 160 - 500 160 - 500 130 - 400

Continuous NS9530 500 - 980 500 - 820 400 - 220

Medium Light interrupted PM T9115 .039-.118 .006-.012 400 - 820 330 - 650 260 - 590

cutting T9125

Heavy interrupted 400 - 820 260 - 590 260 - 400

Low carbon steels, Alloy steels: 1018, 8620 etc. Medium carbon steels, Alloy steels: 1035 - 1045 etc.

High carbon steels, Alloy steels: 4140,4340 ect.

2–18 Grades Relating

pages

(1-1)