Page 630 - Tungaloy Catalog

P. 630

TAC Mills for large depth of cut

TGP5100RIAU

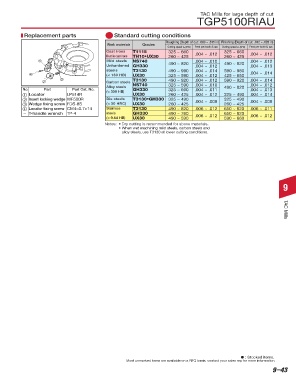

Replacement parts Standard cutting conditions

Roughing (Depth of cut: .060 ~ .315 in) Finishing (Depth of cut: .012 ~ .028 in)

Work materials Grades

Cutting speed vc (SFM) Feed per tooth fz (ipt) Cutting speed vc (SFM) Feed per tooth fz (ipt)

Cast irons T1115 325 ~ 660 .004 ~ .012 325 ~ 660 .004 ~ .012

Ductile cast irons TH10• UX30 260 ~ 425 260 ~ 425

1 Mild steels NS740 .004 ~ .010 .004 ~ .012

Unhardened GH330 490 ~ 820 .004 ~ .012 490 ~ 820 .004 ~ .013

steels T3130 490 ~ 990 .004 ~ .014 590 ~ 980

4 (< 180 HB) UX30 325 ~ 590 .004 ~ .012 425 ~ 650 .004 ~ .014

3 T3130 490 ~ 920 .004 ~ .012 590 ~ 920 .004 ~ .014

2 Carbon steels

Alloy steels NS740 325 ~ 590 .004 ~ .010 490 ~ 820 .004 ~ .012

No. Part Part Cat. No. (< 300 HB) GH330 325 ~ 660 .004 ~ .011 .004 ~ .013

a Locator LP514R UX30 260 ~ 425 .004 ~ .012 325 ~ 490 .004 ~ .014

b Insert locking wedge WF500R Die steels T3130• GH330 325 ~ 490 .004 ~ .008 325 ~ 490 .004 ~ .008

c Wedge fixing screw FDS-8S (< 30 HRC) UX30 260 ~ 425 260 ~ 425

d Locator fixing screw CM4×0.7×14 Stainless T3130 490 ~ 820 .006 ~ .012 650 ~ 820 .006 ~ .011

- T-handle wrench TP-4 steels GH330 490 ~ 760 .006 ~ .012 650 ~ 820 .006 ~ .012

(< 9.84 HB) UX30 490 ~ 590 590 ~ 660

Notes: • Dry cutting is recommended for above materials.

• When wet machining mild steels, carbon steels and

alloy steels, use T3130 at lower cutting conditions.

9

TAC Mills

: Stocked items.

Most unmarked items are available on a RFQ basis, contact your sales rep for more information.

9–43